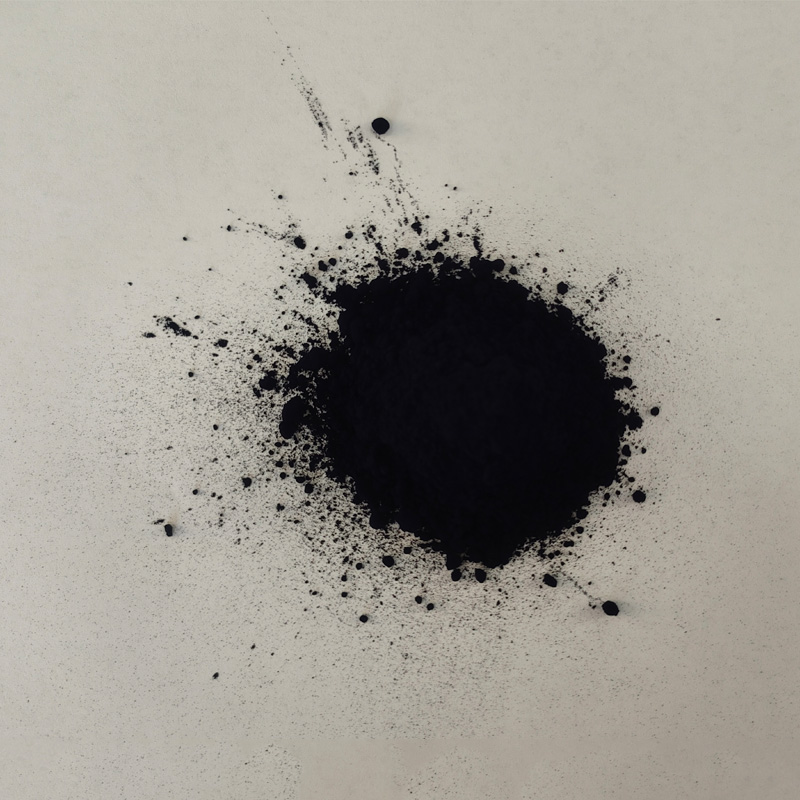

odm indigo compound

Understanding ODM Indigo Compound A Comprehensive Overview

The world of textiles and dyes is rich with history, evolution, and innovation, and one of the most significant components in this realm is indigo. Specifically, the ODM (original design manufacturer) indigo compound stands out as a critical factor in the production of indigo dye, especially in the realm of fashion and fabric. This article aims to delve into the intricacies of ODM indigo compounds, their applications, sustainable aspects, and the future of dyeing in the textile industry.

The Significance of Indigo Dye

Indigo dye has a storied history that dates back thousands of years, revered for its deep blue hue. Traditionally extracted from plants, such as the Indigofera tinctoria, this dye has been utilized in cultures around the world, from ancient Egypt to contemporary denim manufacturing. Its popularity surged due to the vibrant color it imparts and its unique properties, such as colorfastness and versatility.

What is ODM?

An ODM, or Original Design Manufacturer, is a company that designs and manufactures products based on another company's specifications. In the textile industry, ODMs often play a crucial role as they enable brands to develop unique products tailored to their specific design needs while also benefitting from the expertise and resources of the manufacturer. They allow companies to streamline their production processes, minimize costs, and enhance their product offerings.

ODM Indigo Compound Composition and Production

The ODM indigo compound refers specifically to formulations of indigo that are developed and produced by ODMs for various applications, particularly in the textile industry. This compound may comprise pure indigo, synthetic versions, or blended formulations designed to enhance certain properties of the dye, such as solubility, stability, and color intensity.

Historically, traditional indigo extraction was a labor-intensive and time-consuming process. However, with advancements in chemical engineering and biotechnology, contemporary ODMs have refined this process. They now utilize synthetic methods to create indigo in a more controlled, efficient manner. This not only ensures consistency in color but also reduces the environmental impact associated with traditional dye extraction.

odm indigo compound

Sustainable Dying Practices

As environmental concerns rise, the textile industry has faced increasing pressure to adopt sustainable practices. Everyday consumers are becoming more conscious of the manufacturing processes behind their clothing, leading to a demand for eco-friendly dyes. ODMs are responding by innovating sustainable indigo compounds that minimize water usage, reduce toxic runoff, and utilize renewable resources.

For example, some modern ODMs have started using bio-based processes to create indigo from renewable sources, such as sugarcane. Moreover, advances in dyeing techniques, such as digital printing and waterless dyeing methods, contribute significantly to reducing the textile industry's water footprint.

Applications of ODM Indigo Compounds

The versatility of ODM indigo compounds is noteworthy. They are used not only in traditional denim production but also in a wide range of textile applications, including home furnishings, fashion apparel, and even technical textiles. The ability to customize the indigo compound allows ODMs to cater to niche markets, ensuring that clients receive tailored solutions.

Additionally, the fashion industry benefits from ODM indigo compounds through their ability to create unique color palettes, textures, and finishes. From vivid hues to subtle shades, the advancements in dye technology have broadened the creative horizons for designers, allowing them to push boundaries in their collections.

The Future of Indigo in Textiles

As the textile industry continues to evolve, the role of ODM indigo compounds will undoubtedly expand. With increased focus on sustainability and ethical production, the demand for eco-friendly and innovative dyes will grow. ODMs are poised to lead the charge in this transition, developing new compounds and dyeing techniques that will not only preserve the heritage of indigo dyeing but also align with modern values.

In conclusion, ODM indigo compounds represent a crucial intersection of tradition, innovation, and sustainability in the textile industry. Their significance cannot be overstated; as they blend the rich history of indigo dye with contemporary manufacturing practices, they continue to shape the future of fashion and textiles. As consumers become more aware and demanding of sustainable practices, the development and implementation of ODM indigo compounds will play a pivotal role in the evolution of the industry.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.