affordable indigo dyes for vibrant and sustainable fabric coloring solutions

Exploring Cheap Indigoid Dyes An Overview

Indigoid dyes have held a significant place in the history of textile coloration. Known for their vibrant blue hues, these dyes have been utilized for centuries in various cultures around the world. While the traditional indigo dye was derived from the plant Indigofera tinctoria, the quest for affordable alternatives has led to the development of synthetic variants. This article delves into the world of cheap indigoid dyes, exploring their properties, production methods, applications, and environmental considerations.

Properties of Indigoid Dyes

Indigoid dyes are characterized by their excellent lightfastness and washfastness, making them ideal for dyeing textiles. They interact with cellulose fibers like cotton, resulting in a deep, rich blue color that is both appealing and durable. These dyes are also notable for their distinct chemical structure, which consists of a conjugated system that allows them to absorb light effectively, contributing to their vibrant colors.

Historical Context

Historically, indigo was a luxury product, meticulously harvested and processed by artisans. The high cost associated with natural indigo cultivation—intensive labor, lengthy production times, and the requirement of specific climatic conditions—made it inaccessible to many. However, the advent of synthetic chemistry in the late 19th century paved the way for cheaper alternatives, drastically altering the dyeing industry.

Synthetic Indigo Dyes

Synthetic indigo was first produced in laboratories in the late 1800s and became commercially available in the early 1900s. These synthetic dyes are less expensive to produce than their natural counterparts, thanks to industrial-scale manufacturing processes. The most common synthetic indigo dye is made from aniline, a derivative of coal tar. While cheaper and more consistent in quality, synthetic indigo dyes have raised concerns regarding their environmental impact due to the petroleum-based methods of production and chemical waste generated during the process.

Advantages of Cheap Indigoid Dyes

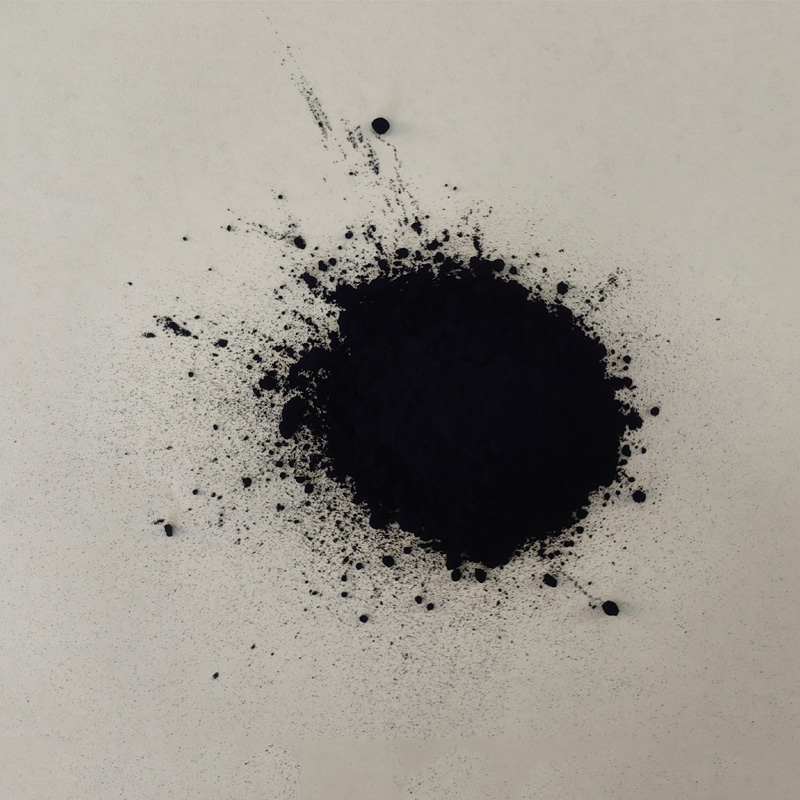

cheap indigoid dyes

The primary advantage of cheap indigoid dyes is their affordability. This cost-effectiveness has made them accessible to smaller textile manufacturers and artisans, allowing for innovative designs and wider market reach. Additionally, their ease of use and improved stability make them suitable for various applications, from denim to home textiles.

Moreover, the development of newer synthetic alternatives, such as the “bio-based” indigo, has garnered attention as an eco-friendly solution. These newer dyes aim to reduce reliance on fossil fuels by utilizing plant-based sources or sustainable chemical processes, thus addressing some of the environmental concerns associated with traditional synthetic indigo.

Applications

Indigoid dyes are predominantly used in the textile industry, especially in the production of denim. The iconic blue jeans that dominate fashion worldwide are often dyed with indigo, thanks to its vibrant color and ability to create distinct fade patterns. Beyond textiles, indigoid dyes are also used in inks, art supplies, and even food products, showcasing their versatility.

Environmental Considerations

As with any chemical dyeing process, the environmental impact of indigoid dyes cannot be overlooked. Traditional dyeing methods often involve large amounts of water and can release toxic chemicals into waterways. Consequently, there has been a push towards more sustainable practices within the industry. Brands are increasingly adopting waterless dyeing technologies, recycling dyes, and utilizing natural coagulants to mitigate environmental harm.

Conclusion

Cheap indigoid dyes play a crucial role in the textile industry, providing vibrant colors at an affordable price. While synthetic alternatives have revolutionized the market, it’s essential to consider the environmental implications of their production and application. The future of indigoid dyes likely lies in a balance between cost efficiency and sustainable practices, ensuring that this beloved hue remains accessible while protecting our planet. As consumers and manufacturers alike become more conscious of their environmental footprint, the evolution of indigoid dyes will continue, shaping the next chapter in the rich history of textile dyeing.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.