Exploring the Quality and Uses of Indigo Powder from Leading Manufacturers

The Rich Hue of Indigo A Dive into Indigo Powder Manufacturing

Indigo powder, known for its deep and rich blue color, has been cherished for centuries not only for its aesthetic appeal but also for its cultural significance. The manufacturing of indigo powder has a storied history, intricately woven into the fabric of ancient dyeing traditions. As a major player in the textile industry, indigo continues to be an essential product that fuels creativity and craftsmanship across the globe.

The process of manufacturing indigo powder begins with the cultivation of indigo plants, primarily *Indigofera tinctoria*. These plants thrive in warm, tropical climates, making regions in India, Africa, and parts of South America pivotal for their growth. Farmers carefully cultivate the plants, ensuring they are harvested at the right time to achieve optimum color yield. The leaves are then harvested and subjected to a fermentation process that allows the release of indigo dye.

Once fermented, a crucial step follows the extraction of the dye. The leaves are soaked and agitated in water, which breaks down the cellular structure and releases the pigment. The mixture undergoes a process called reduction, where oxygen is removed in order to convert the indigo through a series of complex chemical reactions. This results in a soluble form of indigo that can be concentrated and precipitated out.

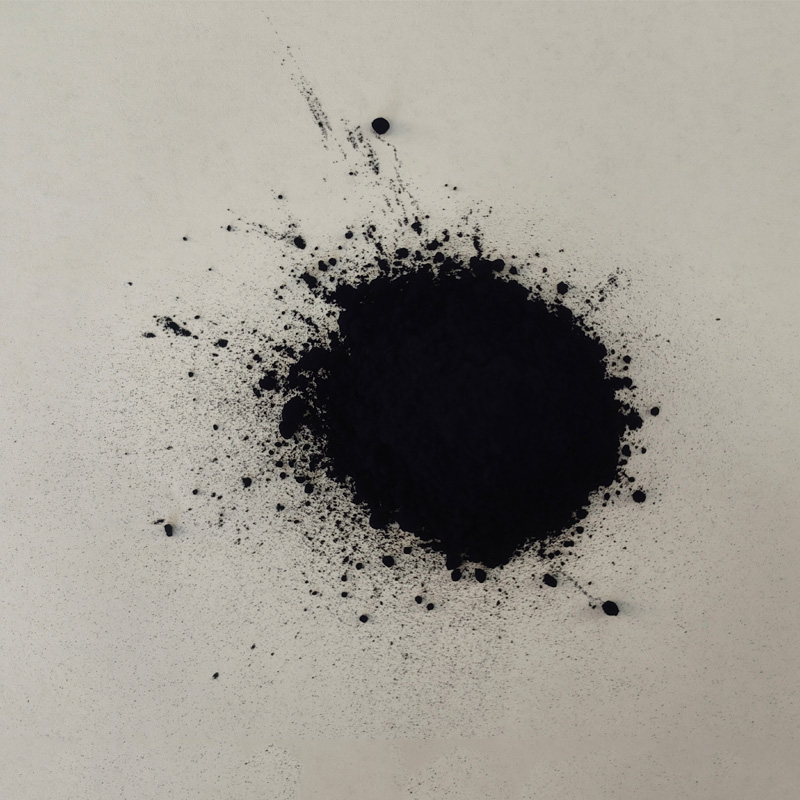

After this extraction, the solid indigo is filtered, dried, and ground into a fine powder. The quality of the powder is of utmost importance, as it affects the final product in terms of color intensity and dyeing properties. High-quality indigo powder exhibits a vibrant hue with excellent lightfastness and stability, making it highly sought after by artisans and manufacturers alike.

color of indigo powder manufacturer

The applications of indigo powder extend far beyond dyeing textiles. Today, it finds uses in art, cosmetics, and even wellness products. The natural and organic nature of indigo makes it an appealing choice for eco-conscious consumers seeking sustainable alternatives.

Moreover, the resurgence of interest in traditional and artisanal dyeing techniques has sparked a renaissance in indigo powder manufacturing. Craftspeople worldwide are exploring innovative ways to incorporate this magical hue into their work, bridging ancient practices with contemporary design.

As the demand for indigo powder continues to grow, manufacturers are increasingly adopting sustainable practices to ensure environmental preservation while maintaining the quality for which indigo is renowned. The future of indigo powder manufacturing not only honors its rich heritage but also champions a responsible approach to production that respects both the artisans and the earth.

In conclusion, the color of indigo powder is much more than a visual delight; it encapsulates a legacy of craftsmanship, sustainability, and cultural significance that continues to inspire innovation in various industries. Whether used in fabric dyeing or artistic expression, this remarkable powder remains an enduring symbol of beauty and tradition.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.