DIY Indigo Dyeing Techniques for Home Crafting Enthusiasts

Exploring OEM Indigo Dyeing at Home A Beginner’s Guide

Indigo dyeing, with its rich heritage and vibrant hues, has fascinated artisans and DIY enthusiasts alike for centuries. Traditionally derived from the leaves of the Indigofera plant, this dye is known for its deep blue color and unique properties. Today, indigo dyeing has become increasingly accessible, with many turning to OEM (Original Equipment Manufacturer) kits that allow individuals to replicate this ancient craft at home. In this article, we will explore the world of OEM indigo dyeing at home, discussing the materials, methods, and tips for achieving beautiful results.

Understanding Indigo Dyeing

Indigo dyeing involves a fermentation process that creates a natural dye from the indigo plant. The dye is unique because it is insoluble in water until it goes through a reduction process, where it becomes soluble and can bind to fabrics. When the dyed fabric is exposed to oxygen, the indigo oxidizes and turns that characteristic deep blue color. This magical transformation is what makes indigo dyeing so captivating.

Necessary Materials

Before diving into the dyeing process, it’s crucial to gather all necessary materials. An OEM indigo dyeing kit typically includes

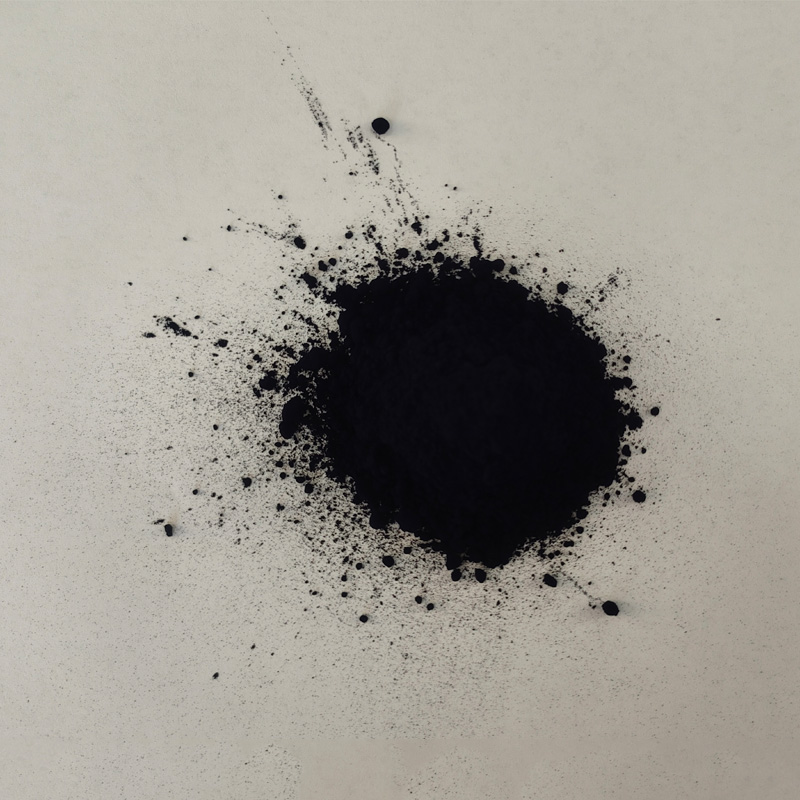

1. Indigo Dye This is usually a powdered form that requires mixing. 2. Pre-reduced Indigo Some kits come pre-reduced, which simplifies the process for beginners. 3. Dyeing Vessel A large container made of non-reactive materials (such as plastic or stainless steel) to hold the dye bath. 4. Protective Gear Gloves, masks, and aprons to protect your skin and clothing from staining. 5. Fabric Natural fibers like cotton, silk, or linen work best as they absorb the indigo dye effectively. 6. Soda Ash This is commonly used as a mordant to help bind the dye to the fabric. 7. Water Distilled water is often recommended for the best results.

The Dyeing Process

1. Preparation Start by preparing your fabric. Wash it to remove any finishes that may inhibit dye absorption. If necessary, scouring the fabric in a soda ash bath can enhance dye penetration.

oem indigo dyeing at home

2. Mixing the Dye Follow the instructions included in your OEM kit to prepare the indigo dye solution. Usually, you need to dissolve the indigo dye powder in water and then add a reducing agent such as thiourea dioxide or another specified chemical.

3. Creating the Dye Bath In your dyeing vessel, mix the reduced indigo solution with water according to your kit’s guidelines. The dye bath should have a consistent, cloudy appearance.

4. Dyeing the Fabric Submerge your prepared fabric into the dye bath, ensuring that it is fully saturated. The longer the fabric stays submerged, the deeper the color will be. Once removed, allow the fabric to oxidize in the air, which will turn it blue.

5. Repeating the Process A single dip usually results in a lighter shade of blue. For deeper colors, repeat this process several times, allowing for oxidation between each dip.

6. Finishing Touches Once you achieve your desired color, rinse the dyed fabric in cold water to remove excess dye. It’s advisable to wash it in a mild detergent afterward to set the color.

Tips for Success

- Experiment with Patterns Indigo dyeing can be combined with various resist techniques, such as shibori or tie-dye, to create stunning patterns. Explore these methods for unique designs. - Test Swatches Always test a small fabric swatch before committing to your main piece. This helps you understand how the dye will react and allows adjustments if necessary. - Avoid Contamination Use dedicated tools for dyeing to prevent unwanted contamination from previous dyes or chemicals.

Conclusion

Indigo dyeing at home is not just a craft; it is a journey into a world of color, culture, and creativity. With the help of an OEM indigo dyeing kit, you can unlock the secrets of this craft and create beautiful, one-of-a-kind pieces. As you embark on this colorful adventure, remember to embrace the learning curve and enjoy every dip into the dye. Happy dyeing!

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.