Unique Indigo Dye Options for Customizing Your Clothing Designs

The Art and Craft of Custom Indigo Dye for Clothes

Indigo dyeing has a rich history that stretches back thousands of years, with its roots deeply embedded in various cultures across the world. Characterized by its deep blue hue, indigo dye offers a unique way to personalize clothing, turning ordinary garments into stunning pieces of art. In recent years, the trend of custom indigo dyeing has surged, inviting craft enthusiasts and fashion-forward individuals alike to explore the beauty of this ancient technique.

The History of Indigo Dyeing

Indigo dyeing was one of the earliest forms of textile dyeing, known to have originated in regions such as India, Africa, and Japan. The dyeing process involves extracting pigment from the leaves of the indigo plant, a process that requires skill and patience. In many cultures, indigo was not just a dye, but also a symbol of wealth and social status. In ancient Japan, for example, the process of dyeing textiles with indigo became an art form, leading to beautiful patterns often seen in traditional garments like kimono.

With the advent of synthetic dyes in the 19th century, natural dyes, including indigo, began to fall out of favor. However, the growing movement toward sustainability and eco-friendly practices has rekindled interest in natural dyes, including custome indigo dyeing. As fashion increasingly embraces individual expression, custom indigo dyeing has emerged as a fashionable way to make a statement and connect with the history and craftsmanship of the textile world.

The Process of Custom Indigo Dyeing

Creating custom indigo-dyed clothing can be a gratifying process that combines artistry and craftsmanship. The fundamental steps involved in the dyeing process include preparing the fabric, creating the dye bath, dyeing the material, and finishing the garment.

1. Preparation The first step involves preparing the fabric. Natural fibers like cotton, linen, or silk work best for indigo dyeing. The fabric must be thoroughly cleaned and sometimes pre-mordanted with a solution to help the dye adhere properly.

custom indigo dye for clothes

2. Creating the Dye Bath The dye bath is created by extracting pigment from fresh or dried indigo leaves or using powdered indigo. This process typically involves fermenting the leaves to allow the dye to develop its rich hue. A basic dye bath also includes water and an alkaline substance, which is necessary for the dye to dissolve effectively.

3. Dyeing Once the dye bath is ready, it’s time for the fun part—dyeing! The fabric is submerged in the dye bath, where it absorbs the color. One unique aspect of indigo dyeing is that the fabric will initially appear green when it is removed from the bath. As it comes into contact with air, the dye reacts and transforms into a deep blue.

4. Finishing After achieving the desired shade, the fabric is rinsed and allowed to air dry, completing the process. The final product can be further treated or embellished, adding personal touches such as patterns and textures.

The Joy of Customization

What makes custom indigo dyeing particularly appealing is the opportunity for personalization. Each dyeing session is unique, resulting in one-of-a-kind garments. Artisans and hobbyists can use various techniques such as shibori, tie-dye, or block printing to create intricate designs that reflect their creativity and style.

Moreover, custom indigo-dyed clothing is not just visually striking but also sustainable. By opting for natural dyes and methods, individuals are making environmentally conscious choices that reduce their carbon footprint compared to mass-produced clothing.

Conclusion

In conclusion, custom indigo dye for clothes offers a profound way to connect with tradition while expressing personal style. This remarkable technique not only highlights the beauty of craftsmanship but also embraces sustainability—a crucial consideration for today’s fashion landscape. Whether you’re a seasoned artisan or a newcomer to the world of dyeing, the journey of creating custom indigo garments can be a fulfilling and inspiring experience. As we celebrate the past while looking toward a more sustainable future, indigo dyeing stands out as a timeless and modern creative outlet for all.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

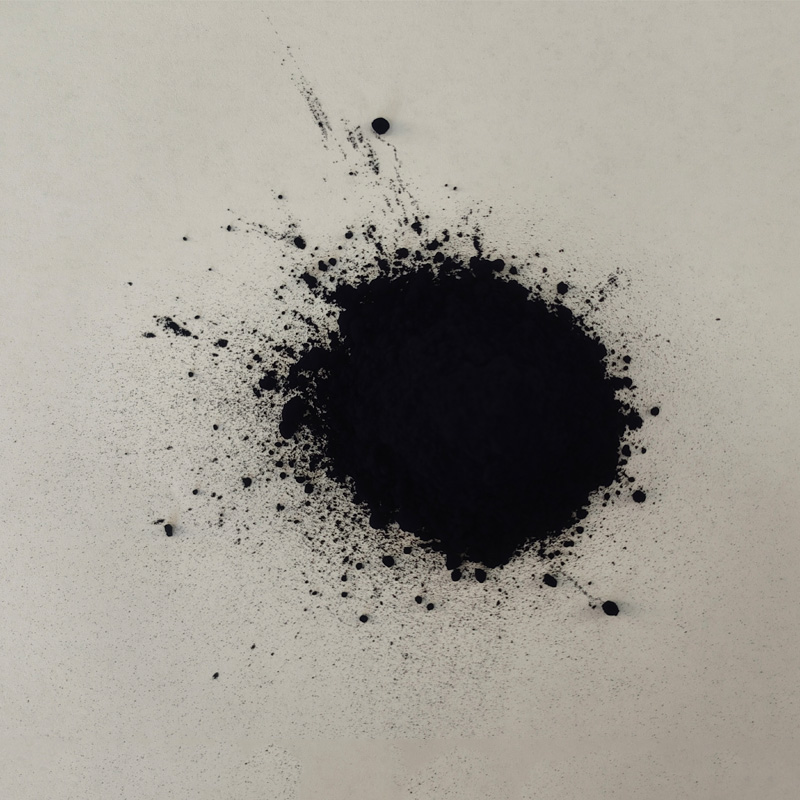

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.