indigo dye fabric manufacturer

The Art and Craft of Indigo Dye Fabric Manufacturing

Indigo dyeing is a time-honored technique that dates back thousands of years, renowned for its rich blue hues and cultural significance across various civilizations. The process of manufacturing indigo dye fabric combines traditional craftsmanship with modern technology, resulting in textiles that are not only visually stunning but also sustainably produced.

The Art and Craft of Indigo Dye Fabric Manufacturing

Once the indigo is extracted, it undergoes a process of reduction and oxidation, transforming it into a soluble form suitable for dyeing fabrics. The fabric, typically made from cotton or silk, is then immersed in the indigo dye bath. This process can be repeated multiple times to achieve varying shades of blue, creating a depth of color that is characteristic of indigo-dyed textiles. Each dip in the dye bath leaves a unique imprint, making every piece one-of-a-kind.

indigo dye fabric manufacturer

In recent years, manufacturers have embraced advanced dyeing technologies while staying true to traditional methods. Innovations such as digital dyeing and eco-friendly indigo substitutes help reduce water usage and chemical pollution. Additionally, many companies are investing in research to create synthetic indigo alternatives that maintain the vibrancy of the color while reducing reliance on natural resources.

The applications of indigo-dyed fabrics are vast. From fashion to home décor, these textiles add a touch of elegance and sophistication. Designers appreciate the timeless appeal of indigo, integrating it into contemporary collections while honoring its historical roots. Furthermore, handcrafted indigo fabrics often come with a narrative, telling stories of heritage and artistry.

As demand for indigo dye fabric continues to rise, manufacturers are also focusing on fair trade practices, ensuring that artisans and workers receive just compensation for their skills. This holistic approach not only preserves traditional dyeing techniques but also fosters economic empowerment within communities.

In conclusion, indigo dye fabric manufacturing is a beautiful blend of art, heritage, and sustainable practices. As the world becomes increasingly aware of the importance of ethical sourcing and environmental responsibility, the timeless appeal of indigo remains irreplaceable, resonating with both consumers and creators alike. Whether through a simple scarf or an elaborate garment, indigo continues to weave its way into the fabric of our lives, celebrating both tradition and innovation.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

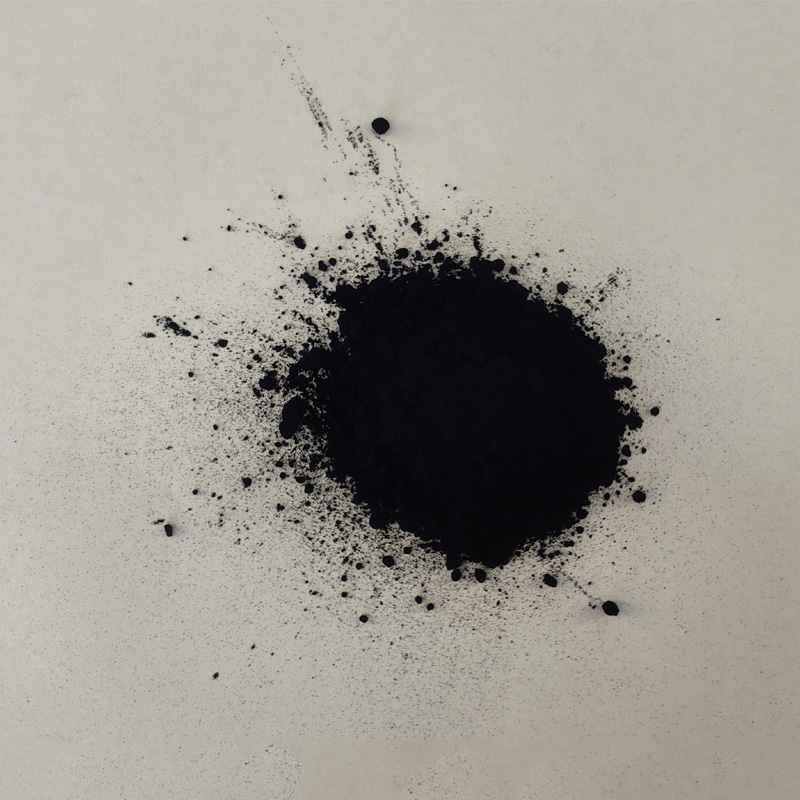

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.