bromo indigo factories

The Evolution and Impact of Bromo Indigo Factories

Bromo indigo, a synthetic dye derived from indigo, has significantly influenced the textile industry since its inception in the late 19th century. The advent of bromo indigo factories marked a transformative period in dye production, integrating chemical innovation with industrial manufacturing processes. This article delves into the history, manufacturing process, and environmental implications of bromo indigo factories.

Historical Context

The discovery of indigo dye dates back thousands of years, with its use prominent in ancient civilizations such as Egypt, India, and China. However, traditional indigo extraction was labor-intensive and costly, making it less accessible. The quest for a more efficient dyeing process led to the development of synthetic indigo in the late 1800s, primarily through the work of German chemist Johann Friedrich Wilhelm Adolf von Baeyer. His synthesis paved the way for the commercial production of synthetic indigo, which included the bromo indigo variant.

Bromo indigo was first produced in the early 20th century and quickly gained popularity due to its vibrant color and ease of application. Factories specializing in bromo indigo emerged, revolutionizing the dyeing industry. These factories became pivotal in meeting the growing demand for textiles while ensuring consistency in color and reducing production costs.

Manufacturing Process

The production of bromo indigo involves several critical steps, starting with the synthesis of its precursor compounds. The primary ingredient, aniline, is derived from coal tar, which undergoes a series of chemical reactions to form bromo indigo. The essential process includes bromination, where bromine is introduced to the indigo structure, resulting in a more stable and brilliant dye.

bromo indigo factories

Once synthesized, the bromo indigo is then processed into a form suitable for application to fabrics. This preparation often involves creating a paste that can be mixed with water or other solvents, allowing for easier application in various dyeing techniques. Factories that specialize in this dye often employ advanced machinery and automated systems to enhance efficiency and replicate high-quality results.

Furthermore, these factories must adhere to strict quality control measures, ensuring that the dye produced meets industry standards for colorfastness, toxicity, and overall performance. This careful attention to detail has solidified bromo indigo's reputation as one of the preferred dyes in the market.

Environmental Impact

Despite the advantages of synthetic dyes like bromo indigo, their production and application raise environmental concerns. The chemical processes involved often lead to the release of hazardous substances into the environment, posing risks to both ecosystems and human health. Additionally, the waste generated during the dyeing process can contaminate water sources if not managed correctly.

In recent years, there has been growing awareness of the environmental footprint of dye production. Many bromo indigo factories have begun implementing sustainable practices, such as closed-loop systems that recycle water and chemicals, thereby minimizing waste. Additionally, the development of eco-friendly alternatives to traditional synthetic dyes is on the rise, driven by consumer demand for more sustainable fashion options.

Conclusion

Bromo indigo factories have played a pivotal role in the evolution of the textile industry, providing a consistent and vibrant dye that has shaped fashion trends for over a century. As the industry continues to evolve, the focus on sustainable practices and environmental stewardship becomes increasingly crucial. Balancing the benefits of bromo indigo with the need for responsible production methods will define the future of dye manufacturing. Advancements in technology and chemistry hold promise for creating dyes that are not only beautiful but also safe for our planet. As consumers become more conscientious about their choices, the industry must adapt to meet these demands, ensuring a harmonious relationship between innovation and sustainability.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

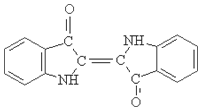

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.