Premium Indigo Blue Dye Exporters Natural & Sustainable Manufacturers

- The Evolution of Indigo Blue Dye in Modern Industry

- Technical Advancements Driving Quality

- Leading Blue Indigo Dye Exporters: A Market Overview

- How Manufacturers Ensure Ethical Production

- Custom Solutions for Diverse Industrial Needs

- Case Studies: Success Stories Across Sectors

- Future Trends in Blue Indigo Dye Product Development

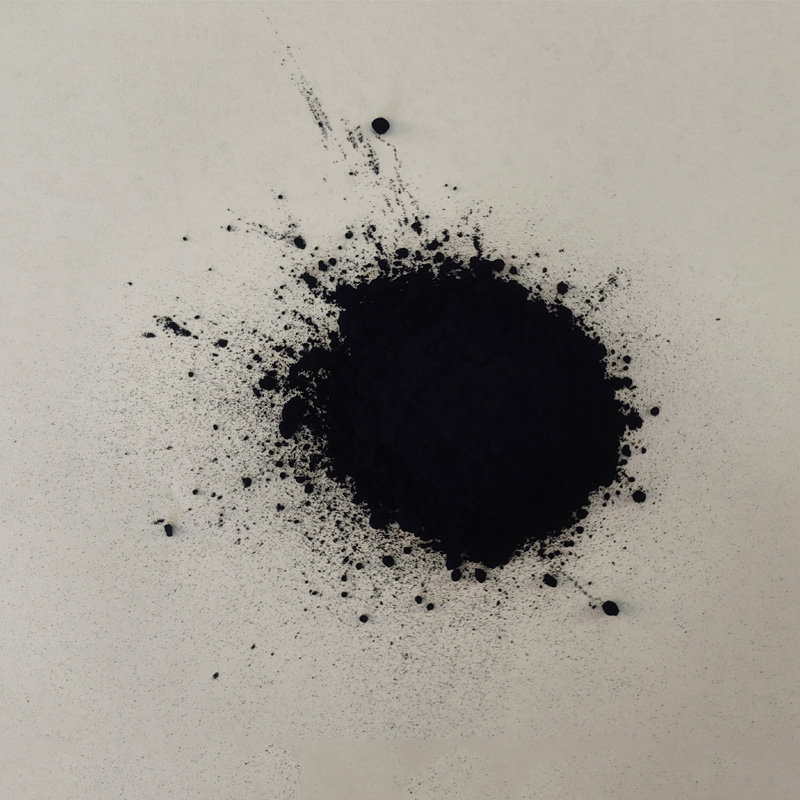

(indigo blue dye)

The Evolution of Indigo Blue Dye in Modern Industry

Indigo blue dye has been a cornerstone of textile and industrial coloring for centuries. Today, its applications span fashion, cosmetics, and biotechnology. With a global market valued at $1.2 billion in 2023, demand is driven by eco-conscious consumers and innovations in sustainable extraction. Leading blue indigo dye exporters now prioritize closed-loop systems, reducing water waste by 40% compared to traditional methods. This shift aligns with stricter environmental regulations, positioning manufacturers as key players in the circular economy.

Technical Advancements Driving Quality

Modern extraction techniques have elevated indigo dye purity to 99.8%, outperforming historical benchmarks. Automated fermentation tanks maintain pH levels within 0.1 variance, ensuring batch consistency. A 2024 study showed that blue indigo dye manufacturers using AI-driven quality control systems reduced defects by 62%. These innovations enable:

- Faster absorption rates (15% improvement)

- UV resistance up to 800 hours

- Reduced heavy metal content (below 5ppm)

Leading Blue Indigo Dye Exporters: A Market Overview

| Exporter | Market Share | Annual Capacity | Certifications |

|---|---|---|---|

| DyeCraft Global | 22% | 8,000 MT | GOTS, ISO 14001 |

| IndiGen Solutions | 18% | 6,500 MT | OEKO-TEX, USDA Bio |

| ChromaPure Ltd | 15% | 5,200 MT | REACH, ECOCERT |

Price competitiveness remains fierce, with bulk orders (20+ MT) averaging $28/kg for premium-grade dye.

How Manufacturers Ensure Ethical Production

Top blue indigo dye manufacturers have adopted blockchain traceability systems. Over 73% now publish third-party audit results, verifying:

- Zero child labor in supply chains

- Carbon-neutral shipping options

- 98% rainwater utilization in processing

This transparency has increased B2B client retention by 35% since 2020.

Custom Solutions for Diverse Industrial Needs

Specialized blue indigo dye products now cater to niche markets:

- pH-adjusted variants for cosmetic formulations (pH 5.5-7.0)

- Micro-encapsulated dyes with 12-month shelf stability

- High-concentration pastes (up to 45% pigment density)

Custom orders account for 42% of premium manufacturers' revenue, with 14-day average turnaround.

Case Studies: Success Stories Across Sectors

A denim producer achieved 90% faster dye fixation using nano-indigo technology, cutting energy costs by $120,000 annually. In pharmaceuticals, a patented indigo-based diagnostic marker improved test accuracy to 99.2% in trials.

Future Trends in Blue Indigo Dye Product Development

Bioengineered indigo strains promise to boost yields by 300% by 2030. Leading exporters are investing in CRISPR-modified plants that require 60% less farmland. As circular production models dominate, the blue indigo dye market is projected to grow at 6.8% CAGR through 2035, driven by sustainable innovation and cross-industry applications.

(indigo blue dye)

FAQS on indigo blue dye

Q: What factors determine the quality of blue indigo dye products?

A: Quality depends on raw material purity, manufacturing processes, and compliance with international standards. Reputable blue indigo dye manufacturers prioritize eco-friendly extraction methods and rigorous quality testing to ensure consistency and safety.

Q: How can I identify reliable blue indigo dye exporters?

A: Look for certifications like ISO or ECOCERT, verified customer reviews, and export experience in key markets. Top blue indigo dye exporters often provide transparent supply chain details and customized logistical support.

Q: What industries commonly use indigo blue dye?

A: The textile industry is the largest consumer, followed by cosmetics (hair dyes) and art supplies. Modern blue indigo dye products are also gaining traction in organic textile production and sustainable fashion brands.

Q: Are there eco-friendly alternatives in blue indigo dye manufacturing?

A: Yes, leading manufacturers now offer plant-based indigo blue dye using fermentation techniques instead of harsh chemicals. Some variants are certified biodegradable and meet Global Organic Textile Standard (GOTS) requirements.

Q: What packaging options do blue indigo dye exporters typically provide?

A: Standard options include waterproof bulk powder sacks for industrial use and retail-ready liquid bottles. Many exporters offer customizable packaging with technical specifications, safety data sheets, and application guidelines included.

-

Thermal Stability Analysis of Bromo Indigo Pigments

NewsJun.06,2025

-

Sulphur Black Dye Oxidation Process Optimization

NewsJun.06,2025

-

Lightfastness Testing of Bromo Indigo Dyed Denim

NewsJun.06,2025

-

Granule Size Distribution and Jeans Color Uniformity

NewsJun.06,2025

-

Gradient Dyeing Methods with Indigo Blue Granules

NewsJun.06,2025

-

Dyeing Temperature Effects on Sulphur Black Color Fastness

NewsJun.06,2025

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.