light indigo color company

Trustworthiness is essentially built on transparency and results. Documenting the production process with digital content such as tutorial videos, detailed blogs on the dye's environmental benefits, and user guides on maintaining dyed fabrics, fortify the artisan’s reputation. Showcasing testimonials and case studies alongside high-resolution photography of the indigo's journey from farm to wardrobe not only solidifies marketing efforts but enhances visibility on search engines. Employing targeted keywords judiciously within this content aligns organically with SEO strategies, reaching audiences passionate about quality, sustainability, and craftsmanship. Challenges like the commercial competition from synthetic dyes persist; however, the advantages of natural indigo in terms of sustainability, unique aging properties, and consumer affiliation with historical and eco-friendly practices offer compelling selling points. Marketing high-quality indigo dye as a premium product requires educating customers about the dye’s lifecycle, its reduced environmental footprint, and its cultural significance. Moreover, reinforcing expertise through workshops, collaborative projects with fashion designers, and academic partnerships can position your brand as a leader in the indigo dye sector. Staying abreast of technological advances such as AI-driven color calibration for consistency or blockchain for transparent supply chains ensures a modern touch to ancient practices, resonating with contemporary market dynamics. In summary, mastering the production of high-quality indigo dye involves a commitment to sustainable practices, an intimate knowledge of traditional techniques, and a proactive approach to market challenges. Crafting a compelling narrative around these elements and maintaining consistent, transparent communication with customers transforms the ancient art of indigo dyeing into a celebrated modern commodity.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

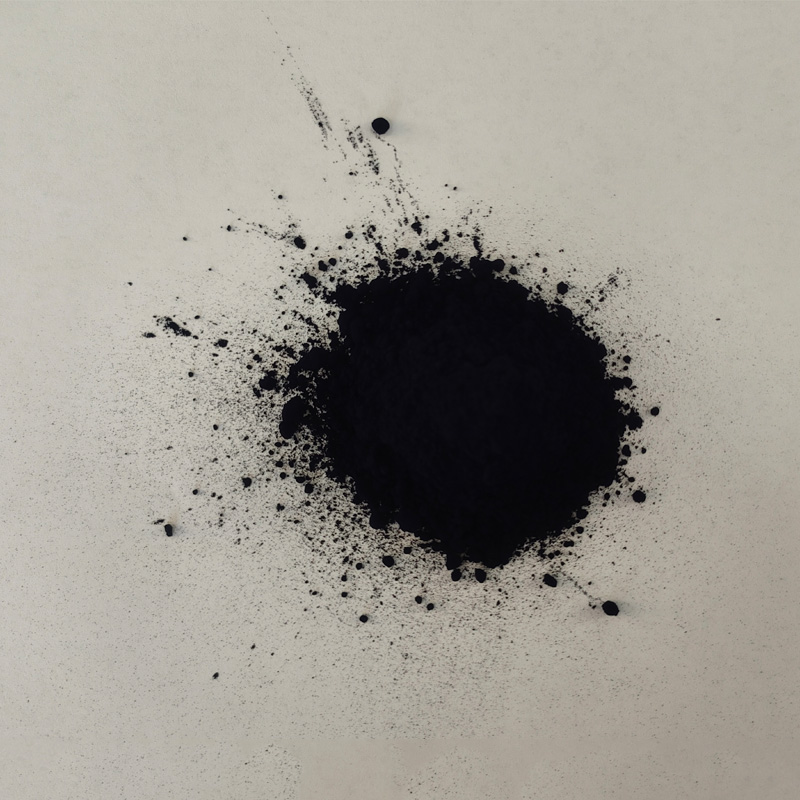

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.