odm indigo dyeing machine

Exploring the Innovations in ODM Indigo Dyeing Machines

The textile industry is in a constant state of evolution, driven by advancements in technology and the demand for sustainability. One of the notable innovations in this sector is the ODM indigo dyeing machine. This machine represents a significant leap forward in the dyeing process, specifically for denim fabrics, which are typically dyed using traditional methods that can be resource-intensive and environmentally damaging.

Indigo dyeing has been a cornerstone of denim production for centuries, with its distinctive deep blue hue being a hallmark of quality denim. However, traditional indigo dyeing processes often involve the use of large amounts of water and chemicals, contributing to environmental pollution and resource depletion. This is where ODM indigo dyeing machines come into play. These machines have been designed to minimize the environmental impact of dyeing while enhancing efficiency and product quality.

The key features of ODM indigo dyeing machines include advanced technology that allows for precise control over the dyeing process. This results in more consistent color application and reduces the occurrence of defects such as uneven dyeing and fading. Additionally, these machines often incorporate closed-loop systems that recycle water and dye to significantly reduce waste. By capturing and reusing water, ODM machines contribute to significant water conservation—an essential factor in an industry that heavily relies on this precious resource.

Another innovative aspect of ODM indigo dyeing machines is their ability to work with a variety of fabrics. While denim is the primary focus, the versatility of these machines allows for the dyeing of other materials, broadening their application and market appeal. This adaptability is crucial in today's fast-paced fashion industry, where trends can change rapidly, and manufacturers need to respond swiftly.

odm indigo dyeing machine

In terms of energy consumption, ODM machines are engineered to be more energy-efficient than their predecessors. This not only lowers operational costs for manufacturers but also aligns with the growing emphasis on sustainable practices within the industry. By reducing energy consumption, ODM machines help mitigate the carbon footprint associated with textile production, making them an attractive option for eco-conscious brands.

Moreover, the automation features found in modern ODM indigo dyeing machines lead to improved labor efficiency. With fewer manual interventions, manufacturers can streamline their processes, reduce human error, and increase productivity. This translates into faster turnaround times and a more agile approach to production, which is invaluable in meeting the demands of consumers for quicker delivery times.

As sustainability continues to shape the future of the textile industry, ODM indigo dyeing machines are at the forefront of this transformation. Their ability to reduce environmental impact while enhancing quality and efficiency positions them as a pivotal technology for manufacturers looking to adopt greener practices.

In conclusion, ODM indigo dyeing machines symbolize a significant advancement in the quest for sustainable and efficient textile production. By minimizing waste, conserving water and energy, and promoting versatility in fabric processing, these machines not only cater to the needs of modern manufacturers but also align with the values of today’s environmentally conscious consumers. As the industry progresses, the role of such innovative machines will be crucial in balancing tradition with modern sustainable practices, ensuring that the legacy of denim and indigo dyeing continues in an eco-friendly manner.

-

Denim Indigo Dye Supports Sustainable Fashion

NewsAug.28,2025

-

Black Sulfur Elevates Material Durability

NewsAug.28,2025

-

The Alchemist's Indigo: A Forgotten Dye Of The Ancient World

NewsAug.28,2025

-

Sustainable Sulphur Black Dyeing: Eco-Friendly Methods For Textile Factories

NewsAug.28,2025

-

Sulfur Black Dyes: The Superior Choice For Industrial Applications

NewsAug.28,2025

-

Indigo Blue: History And Cultural Significance

NewsAug.28,2025

-

Global Sulphur Black Suppliers: Market Trends And Future Demand

NewsAug.28,2025

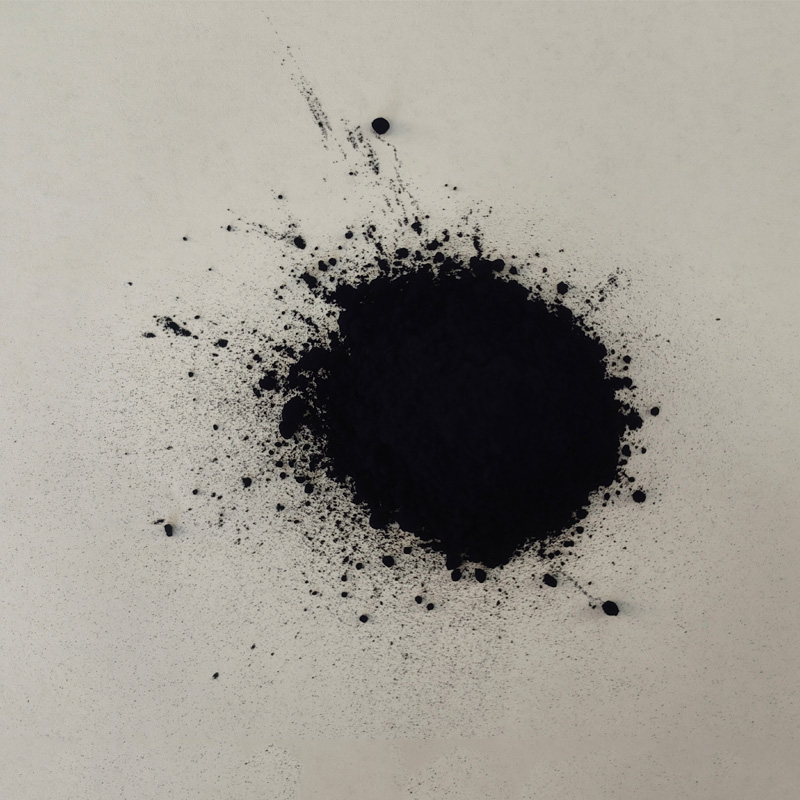

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.