make indigo manufacturers

The Art and Science of Indigo Production

Indigo, a deep blue dye extracted from the leaves of the indigo plant, has been cherished for centuries for its vibrant color and unique properties. This natural dye has a rich history, deeply rooted in both art and industry, and its production involves intricate processes that combine traditional techniques with modern innovations. In this article, we will explore the journey of indigo from plant to pigment, the role of indigo manufacturers, and the resurgence of indigo in contemporary markets.

The Historical Significance of Indigo

Indigo dyeing dates back thousands of years and can be traced to ancient civilizations in India, Egypt, and China. Historically, indigo was considered more valuable than gold and was often used to signify wealth and status. It played a crucial role in trade routes, especially during the colonial era, where European powers capitalized on indigo’s popularity. The rich, alluring hue of indigo made it a sought-after commodity, leading to large-scale production in colonies across the Americas and Asia.

Cultivation of Indigo Plants

Indigo dye is primarily derived from the leaves of the *Indigofera* plant. The cultivation process begins with the careful selection of high-quality seeds, which are sown in nutrient-rich soil. Indigo plants thrive in warm climates with abundant sunlight and rainfall. Farmers must ensure their fields are free of weeds to allow the indigo plants to grow unimpeded.

Once the plants reach maturity, typically within 90 to 120 days, the leaves are harvested. This process requires skill and precision, as the leaves must be picked at the right time to ensure optimal dye yield. After harvesting, the leaves undergo a fermentation process, during which they are soaked in water to release indican, a compound that converts to indigo dye through a series of chemical reactions.

The Fermentation Process

The fermentation process is a crucial step in transforming indigo leaves into dye. The harvested leaves are placed in large vats filled with water, where they are allowed to ferment for several hours. During this time, enzymes break down the indican, releasing indigo pigment. The mixture becomes a thick, frothy fluid that is then subjected to aeration, which helps precipitate indigo dye from the solution.

make indigo manufacturers

After fermentation, the indigo precipitate settles to the bottom of the vat and is collected. This crude indigo is then dried and often processed further into various forms, such as cakes or powders, making it easier to handle and store.

The Role of Indigo Manufacturers

Indigo manufacturers play a vital role in the dyeing industry. They are responsible for the large-scale production and processing of indigo to meet the demands of textile manufacturers and artists alike. With advancements in technology, many indigo manufacturers have integrated sustainable practices into their operations. This shift addresses growing concerns about environmental impact and ethical production.

Modern indigo manufacturing often incorporates bioengineering techniques to optimize dye yield and reduce water usage. Some manufacturers are exploring the cultivation of genetically modified indigo plants that require fewer resources while still producing high-quality dye. Furthermore, innovative extraction methods aim to minimize waste and enhance the dyeing process, making it more efficient.

The Resurgence of Indigo in Contemporary Markets

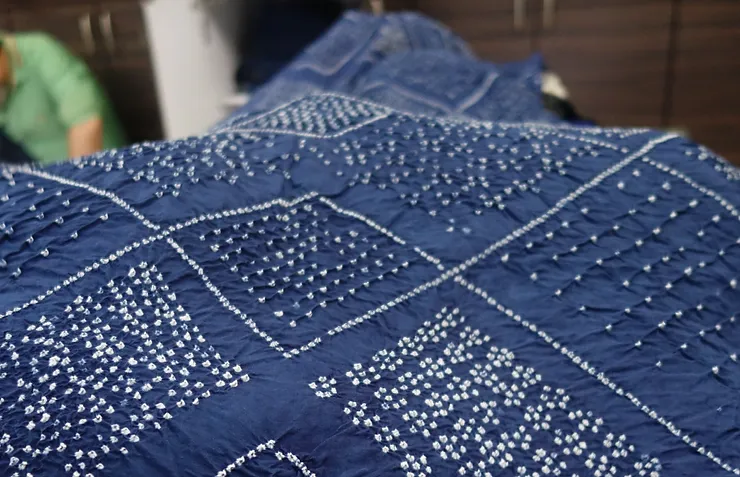

In recent years, there has been a renaissance of interest in natural indigo, driven by a growing demand for sustainable and eco-friendly products. Consumers are increasingly turning away from synthetic dyes, which can be harmful to both the environment and health. As a result, natural indigo has found its way back into fashion, textiles, and artisanal crafts.

Many fashion designers and textile artists are collaborating with indigo manufacturers to create unique, handcrafted pieces that showcase the beauty of this traditional dye. By spotlighting the rich history and craftsmanship associated with indigo, contemporary artisans are breathing new life into the age-old art of indigo dyeing, celebrating its aesthetics and significance.

Conclusion

From its historical roots to modern-day applications, indigo stands as a testament to the interplay of art, culture, and industry. The role of indigo manufacturers is critical in preserving this ancient practice while meeting contemporary demands. As the world moves towards more sustainable practices, indigo’s legacy continues to thrive, captivating new generations with its stunning hues and rich history. Whether in the form of a beautifully dyed fabric or a cherished piece of art, indigo remains a symbol of creativity and tradition, bridging the past with the future.

-

Thermal Stability Analysis of Bromo Indigo Pigments

NewsJun.06,2025

-

Sulphur Black Dye Oxidation Process Optimization

NewsJun.06,2025

-

Lightfastness Testing of Bromo Indigo Dyed Denim

NewsJun.06,2025

-

Granule Size Distribution and Jeans Color Uniformity

NewsJun.06,2025

-

Gradient Dyeing Methods with Indigo Blue Granules

NewsJun.06,2025

-

Dyeing Temperature Effects on Sulphur Black Color Fastness

NewsJun.06,2025

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.