Indigo Powder Suppliers and Manufacturers for Quality Dyeing Solutions

The Journey of Indigo Powder From Ancient Roots to Modern Manufacturing

Indigo powder, a natural dye that has been cherished for centuries, has a rich history that dates back to ancient civilizations. This deep blue pigment, derived from the leaves of the indigo plant, particularly Indigofera tinctoria, has been used for dyeing textiles, creating art, and even in traditional medicine. In recent years, the resurgence of interest in organic and sustainable materials has brought indigo powder back into the spotlight, leading to a growing market for indigo powder manufacturers.

Historical Significance of Indigo

The use of indigo can be traced back over 6,000 years to ancient Egypt, where it was used for dyeing fabrics and for cosmetic purposes. It was highly prized and often reserved for the garments of the elite. The cultivation of indigo spread to various parts of the world, including India, Africa, and Japan, where each culture developed its unique techniques for extracting the dye. In India, the method of extracting indigo dye became a sophisticated craft, often involving complex fermentation processes to obtain the vibrant blue color.

The production of indigo also had significant economic implications. It was one of the few dyes that could produce a fast color, making it desirable for textiles. The transatlantic trade of indigo became notable, with European colonizers exploiting indigo cultivation in the Americas. However, by the 19th century, synthetic dyes replaced traditional indigo, leading to a decline in natural indigo cultivation.

A Resurgence of Interest

In today’s world, the demand for natural dyes is experiencing a renaissance. Environmental concerns regarding synthetic dyes have pushed manufacturers and consumers towards sustainable alternatives. Indigo powder, with its plant-based origins and environmental benefits, has become a popular choice for eco-conscious brands. Natural indigo dyeing is perceived as more sustainable, as it typically involves less water and fewer chemicals compared to synthetic alternatives.

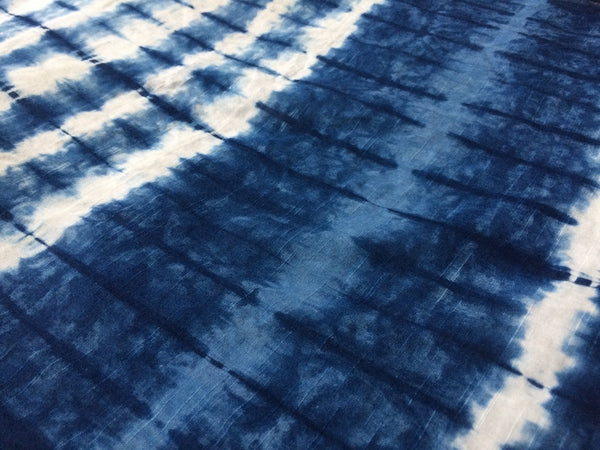

indigo powder indigo powder manufacturers

The quest for authenticity in consumer products has also fueled interest in indigo powder. Artisans and designers are turning to traditional techniques to create unique, handcrafted textiles that tell a story. Indigo dye is now utilized in various applications, from fashion to home décor, reflecting a blend of heritage and modern design.

Indigo Powder Manufacturers The Modern Landscape

The current market for indigo powder manufacturers is diverse, ranging from small-scale artisanal producers to larger industrial operations. Many manufacturers emphasize sustainable and eco-friendly practices, often sourcing raw indigo leaves from local farmers who are committed to organic cultivation methods. This not only supports local economies but also ensures the production process respects the environment.

Manufacturers employ various techniques to convert indigo leaves into powder, including drying, fermenting, and grinding. The quality of the indigo powder can vary based on the methods and practices of production. As consumers become more discerning, manufacturers are investing in quality control and transparency, often providing detailed information about the sourcing and production of their indigo.

Conclusion

Indigo powder, with its deep historical roots and modern-day relevance, represents a unique intersection of tradition and innovation. As the world leans towards sustainability, the role of indigo powder manufacturers becomes increasingly important. Their commitment to quality, sustainability, and fair trade practices not only preserves a cherished craft but also contributes to a more responsible future for fashion and textiles. Whether in the form of dyestuff for artisans or as a natural pigment in various applications, indigo powder continues to captivate and inspire, reminding us of the beauty found in nature and tradition. As we embrace this rich heritage, we are also paving the way for a more sustainable and conscientious approach to consumption.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.