odm sulphur black 2br

Understanding ODM Sulphur Black 2BR Properties, Applications, and Production

Introduction to Sulphur Black 2BR

Sulphur Black 2BR is a synthetic dye belonging to the class of sulphur dyes, which are known for their excellent colorfastness and affordability. This specific dye is commonly used in the textile industry for dyeing cotton, viscose, and other cellulose fibers. It offers a rich, deep black hue which is highly desirable in various applications. The unique chemical structure of Sulphur Black 2BR allows it to meet the demands of today's textile producers while maintaining environmental considerations.

Chemical Composition and Properties

Sulphur Black 2BR is primarily composed of polysulfide compounds. Its chemical structure includes multiple sulfur atoms attached to an aromatic ring, which contributes to its unique coloration properties. One of the key advantages of sulphur dyes, including 2BR, is their solubility in alkaline solutions. This property facilitates the dyeing process, as the dye can penetrate the fiber more effectively during the application process. Moreover, Sulphur Black 2BR is known for its excellent wash and light fastness, which makes it suitable for products that undergo extensive laundering or exposure to sunlight.

Dyeing Process and Techniques

The application of Sulphur Black 2BR involves several key steps that ensure even coloring and optimal fastness properties. The dyeing process typically includes the following stages

1. Preparation The fabric must be pre-treated to remove any impurities, oils, or finishes that might hinder dye uptake. This might involve scouring or bleaching. 2. Dyeing The dye is dissolved in an alkaline solution, activating the dye for application. The fabric is then submerged in this solution, and sodium sulfide is often added to facilitate the dye uptake. It's essential to maintain the temperature and pH level within specific parameters to achieve the desired color depth.

3. Oxidation Once the desired color is achieved, the fabric must be oxidized to stabilize the dye molecules within the fibers. This is usually done using sodium dichromate or other oxidizing agents.

4. Finishing After dyeing and oxidation, the fabric is thoroughly rinsed to remove any excess dye and chemicals. Finally, it may undergo finishing processes such as softening or setting to enhance its texture and appearance.

odm sulphur black 2br

Applications Across Industries

Sulphur Black 2BR is predominantly used in the textile industry, but its applications extend beyond just fabrics. Here are some notable uses

- Apparel From denim jeans to t-shirts, Sulphur Black 2BR is often chosen for its deep, rich color that appeals to fashion trends.

- Home Textiles Items such as curtains, bed linens, and upholstery fabrics benefit from the durability and aesthetic qualities of this dye.

- Non-Woven Fabrics Sulphur Black 2BR is also utilized in non-woven textiles, which are increasingly used in medical and hygiene products.

- Leather While not as common, some leather products may also employ this dye, especially for those aiming for a specific aesthetic.

Environmental Considerations

While Sulphur Black 2BR offers many advantages, its production and application must consider environmental impacts. The dye industry has faced scrutiny over the years for water pollution and chemical waste. However, many manufacturers are adopting sustainable practices, such as closed-loop water systems and eco-friendly chemicals, to mitigate these effects. Additionally, research into biodegradable alternatives and lower-impact synthetic dyes is ongoing, highlighting the industry's commitment to sustainability.

Conclusion

In summary, ODM Sulphur Black 2BR is a crucial dye in the textile industry, known for its vibrant color and excellent fastness properties. Its comprehensive dyeing process ensures high-quality results across various applications, from fashion to functional materials. As the industry continues to adapt to environmental challenges, ongoing innovations will likely enhance the sustainability and efficacy of Sulphur Black 2BR, securing its place in the fabric of modern textiles.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

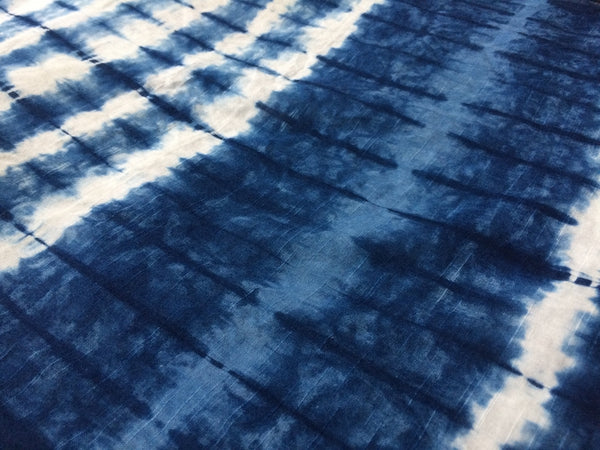

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.