odm sulphur black msds

Furthermore, the trustworthiness of ODM Sulphur Black is reinforced through transparent supply chain practices. Manufacturers provide detailed MSDS documentation with every shipment, outlining potential hazards, first-aid measures, fire-fighting techniques, and safe disposal norms. Such openness not only fulfills legal obligations but engenders a sense of reliability, cementing the manufacturer's reputation. For textile professionals seeking to optimize the use of Sulphur Black, understanding the MSDS becomes a critical part of operational excellence. The document is not just a regulatory requirement but a powerful tool that, when correctly interpreted, can enhance efficiency and safeguard the workforce. Professionals advocate for periodic auditing of MSDS information, ensuring it aligns with current industrial best practices and technological advancements, thus maintaining a proactive stance on safety and quality control. Incorporating ODM Sulphur Black into the production process demands an integration of experience, expertise, adherence to authoritative guidelines, and fostering trustworthiness at every operational level. By embedding these core principles into the handling of Sulphur Black, businesses can not only ensure their products meet the highest standards of quality and safety but also position themselves as pioneers of industry best practices, earning the respect and continued patronage of their consumers.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

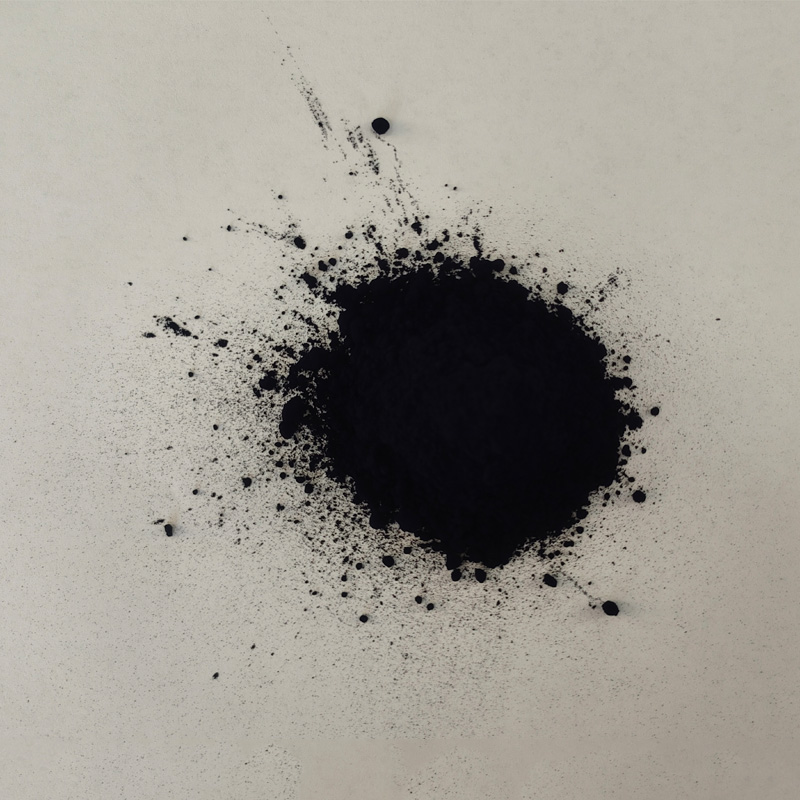

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.