china dye production

The Evolution of Dye Production in China A Historical and Industrial Perspective

Dye production in China has a rich history that stretches back thousands of years, reflecting the country’s profound connection with color and textiles. From ancient dynasties to the modern industrial era, the dye industry has evolved significantly, shaping cultural aesthetics and economic practices. Today, China stands as one of the world's largest producers of dyes, playing a pivotal role in the global textile market.

Historical Background

The origins of dyeing in China can be traced to the early days of the Yellow River civilization, where natural dyes derived from plants, minerals, and insects were used to color textiles. Historical texts suggest that during the Han dynasty (206 BCE – 220 CE), advanced dyeing techniques were developed, enabling artisans to create a broader spectrum of colors. Indigo dyeing, in particular, became a staple in textile production, leading to the well-known blue and white porcelain, which remains a symbol of Chinese artistry.

During the Tang (618–907 CE) and Song (960–1279 CE) dynasties, the demand for vibrant colors surged due to increased trade along the Silk Road. This period witnessed the rise of indigo and other natural dyes, such as madder and safflower. The intricate tie-dye and batik techniques also flourished, showcasing the artistic capabilities of Chinese dyers.

The Industrial Revolution and Synthetic Dyes

The turning point for dye production came with the Industrial Revolution in the 19th century and the subsequent development of synthetic dyes. In the late 1800s, European chemists first synthesized artificial dyes, which quickly gained popularity for their vibrant colors and cheap production costs. As these synthetic dyes began to enter the Chinese market, local dyers faced challenges adapting to the new technology.

By the early 20th century, China began to invest in modern dye production techniques. Factories were established, and knowledge of synthetic dye chemistry was disseminated among local artisans. This not only transformed dye production but also contributed to the growth of the textile industry as a whole. The vibrant colors produced by synthetic dyes allowed for greater creativity in textile design, ultimately leading to increased exports.

china dye production

Modern Dye Industry and Global Impact

Today, China is the largest producer of dyes in the world, exporting a significant portion of its output to various countries. The Chinese dye industry has embraced modern technologies, utilizing advanced chemical processes to produce a wide range of dye products, including reactive, acid, and disperse dyes. Innovations in eco-friendly dyeing practices have also emerged, driven by international demand for sustainable production methods.

The rapid expansion of the dye industry is closely linked to China’s booming textile sector. As one of the world’s largest manufacturers of clothing and fabric, China’s dye production plays a crucial role in meeting the needs of global markets. The country produces several hundred thousand tons of dyes annually, catering to various applications beyond textiles, such as plastics, leather, and paper.

Environmental Considerations

However, the growth of the dye industry has not come without challenges, particularly concerning environmental sustainability. Traditional dyeing processes can cause significant pollution, leading to concerns about water contamination and toxic waste. In recent years, the Chinese government has implemented stricter environmental regulations aimed at curbing pollution and promoting sustainable practices.

The dye industry is increasingly exploring eco-friendly alternatives, such as natural dyes and innovative waste treatment technologies. Moreover, advancements in biotechnological methods for dye production are being researched to mitigate harmful environmental impacts while maintaining the industry's economic viability.

Conclusion

In conclusion, the evolution of dye production in China reflects a tapestry of cultural heritage, technological advancement, and industrial growth. From the ancient use of natural dyes to the modern embrace of synthetic and sustainable practices, the Chinese dye industry has continuously adapted to meet the changing demands of society and global markets. As the world moves towards a more sustainable future, the ability of China’s dye industry to innovate and evolve will be critical in shaping the landscape of textile production and beyond.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

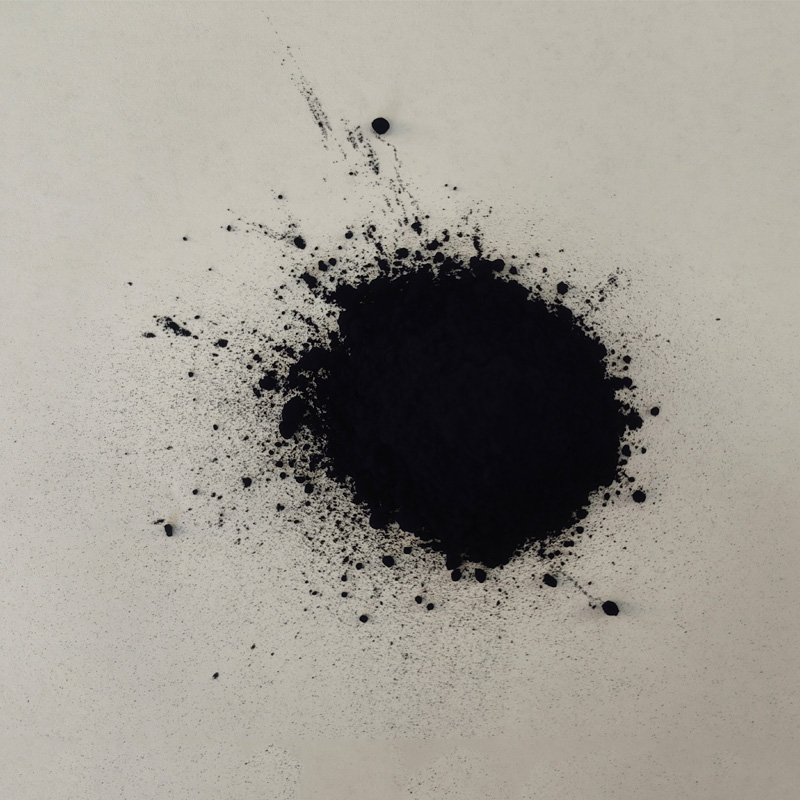

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.