Premium Indigo Dyeing Manufacturers | Eco-Friendly Textile Solutions

The Art and Science of Indigo Dyeing A Look at Manufacturers

Indigo dyeing is an ancient practice that has captivated artisans, designers, and consumers for centuries. Revered for its deep blue hues and rich cultural significance, indigo dyeing has a complex manufacturing process that blends art, science, and tradition. Today, numerous manufacturers around the globe work to produce high-quality indigo dye, each contributing unique techniques and innovations to this timeless craft.

The History of Indigo Dyeing

Indigo dyeing dates back thousands of years, with archaeological evidence suggesting its use in ancient Egypt, India, and China. Historically derived from the leaves of the indigo plant, the dye has played a significant role in societal development, fashion, and trade. The process of extracting dye from indigo plants is labor-intensive, requiring skill and knowledge passed down through generations. In many cultures, indigo dyeing is not just a method of color application; it is also a ceremonial and communal activity.

The Manufacturing Process

Modern indigo dye manufacturers typically follow a more industrialized version of this age-old craft, using both natural and synthetic indigo. The natural dye is sourced from plants like Indigofera tinctoria and is prized for its vibrancy and eco-friendliness. The manufacturing process begins with the harvesting of indigo leaves, which are then fermented to extract the indigo compound. This liquid is treated with lime and air to create a dye vat that can be used to dye fabrics.

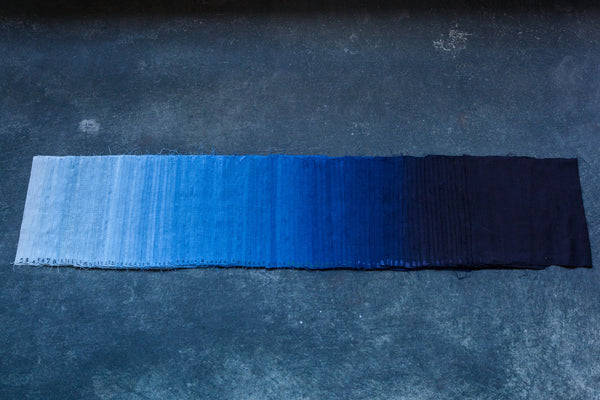

On the other hand, synthetic indigo is produced from chemical processes that allow for mass production and consistency in color, often making it a more affordable option for manufacturers. While this method lacks the organic qualities of natural indigo, it provides a wide range of colors and shades, catering to diverse fashion and design needs.

indigo dyeing manufacturers

Eco-Friendly Practices

As environmental concerns have become more prevalent, many indigo dye manufacturers are striving to adopt sustainable practices. Brands are exploring organic farming methods for cultivating indigo plants and utilizing eco-friendly production methods that reduce water and chemical use. Some manufacturers have also begun to implement closed-loop systems that recycle water used in the dyeing process, thereby minimizing waste and environmental impact.

Moreover, there is a growing trend toward promoting local artisans and small-scale manufacturers who specialize in traditional indigo dyeing techniques. These artisans often work within their communities, ensuring that their skills are passed down while also supporting local economies.

The Global Demand for Indigo

The resurgence of interest in sustainable fashion has sparked a renewed demand for indigo-dyed products across the globe. From high-end fashion collections to artisanal home decor, indigo’s versatility and aesthetic appeal are being embraced by a wide range of industries. Manufacturers are increasingly collaborating with designers and brands to incorporate unique indigo patterns and techniques into their collections, bridging the gap between tradition and contemporary style.

In conclusion, indigo dyeing is more than just a manufacturing process; it is a synthesis of artistry, culture, and sustainability. As various manufacturers continue to innovate while respecting the traditional practices, the future of indigo dyeing looks vibrant. By supporting these manufacturers, consumers are not only investing in beautiful, timeless products but also contributing to the preservation of a rich cultural heritage that spans across centuries and continents.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.