Creating Your Own Indigo Dye Production Facility at Home

Creating an Indigo Dye Factory A Journey into Sustainable Fashion

In the world of textiles, indigo dye has held a significant place for centuries, prized for its rich blue hue and cultural significance. As the fashion industry becomes increasingly aware of its environmental impact, the revival of traditional methods of indigo dyeing presents an exciting opportunity to create a sustainable dye factory. This article explores the creation of an indigo dye factory, including the methods of production, the cultural importance of indigo, and the benefits of adopting such practices in the modern textile industry.

The History of Indigo Dyeing

Indigo dyeing dates back over 6,000 years, with roots in ancient civilizations across Africa, Asia, and the Americas. The process of extracting dye from the indigo plant (Indigofera tinctoria) is labor-intensive and requires traditional craftsmanship. From the export of indigo in India to the blue jeans of contemporary Western fashion, indigo's journey reflects a complex interplay of cultural exchange and economic impact. A factory dedicated to the production of indigo dye would not only honor this rich history but also provide a platform for reviving time-honored techniques that have been overshadowed by synthetic dyes.

Setting Up the Factory

Establishing an indigo dye factory begins with sourcing raw materials the indigo plants themselves. Cultivating indigo in an environmentally responsible manner is essential. This can involve organic farming practices that avoid harmful pesticides and encourage biodiversity. The next step is to implement a sustainable production process that minimizes water usage and waste. Traditional techniques such as fermentation and natural dyeing can be employed, allowing for a reduction in chemical treatments often associated with synthetic dyes.

The factory layout should include areas for dye extraction, dyeing, and drying. In the extraction phase, the leaves of the indigo plant are harvested and fermented to create a rich dye solution. The dyeing process requires careful temperature and timing control to ensure that fabrics absorb the color evenly. Once dyed, textiles must be dried properly to fix the color, preserving its vibrancy.

Craftsmanship and Community Involvement

make indigo dye factory

A successful indigo dye factory is about more than just production; it’s about building a community. Engaging local artisans who have traditional dyeing skills can promote knowledge sharing and foster a sense of pride in local craftsmanship. Offering training programs can empower individuals with the necessary skills while ensuring that the cultural significance of the craft is preserved.

Incorporating storytelling into the product line can also resonate with consumers who are increasingly interested in the origins of what they buy. Each fabric dyed in the factory could tell a story – about the farmers who grow the indigo, the artisans who execute the dyeing, and the sustainable practices that make the product unique.

Environmental and Economic Benefits

The environmental impact of synthetic dyes is alarming, with many processes discharging toxic waste into waterways and using excessive amounts of water. An indigo dye factory that employs sustainable practices can significantly reduce this pollution. By focusing on organic cultivation and traditional techniques, the factory not only lessens its ecological footprint but also promotes biodiversity and healthy ecosystems.

Economically, such a factory can provide jobs for the community, stimulate local economies, and support sustainable agriculture. As consumers become more inclined to make ethical choices, a factory producing eco-friendly indigo dye could cater to the burgeoning market for sustainable fashion.

Conclusion

The establishment of an indigo dye factory is a venture that merges tradition with sustainability, offering an alternative to the harmful practices prevalent in the modern textile industry. By focusing on eco-friendly methods, uplifting local communities, and sharing the rich history of indigo dyeing, such an initiative can pave the way for a more sustainable fashion future. Embracing the indigo legacy not only enriches our aesthetic experience but also reconnects us with our planet and the artistry of textile production. Through conscious choices, we can inspire a shift toward greater sustainability in fashion, one dye vat at a time.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

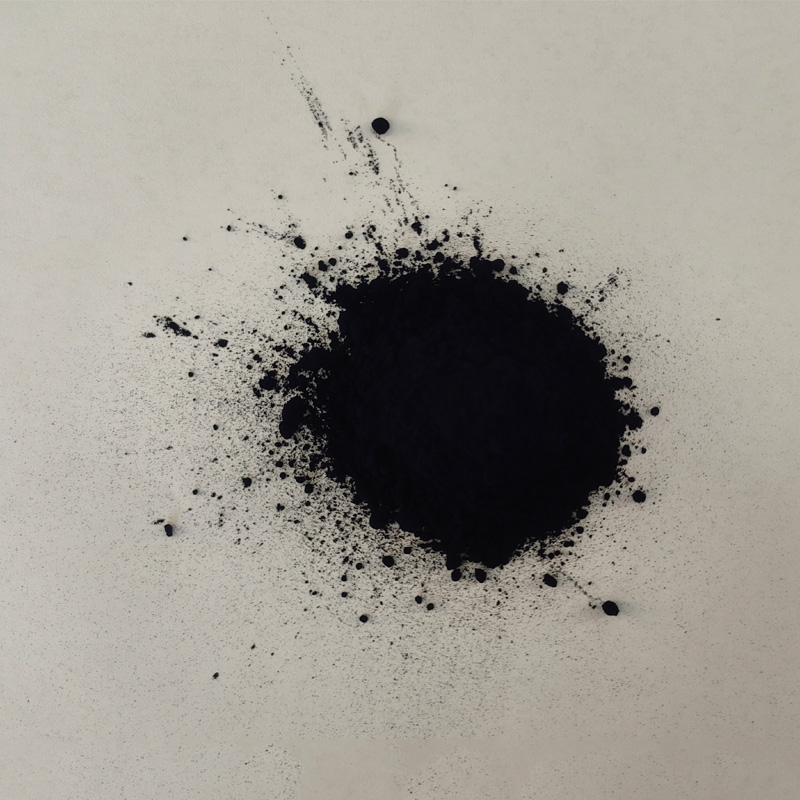

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.