indigo tie and dye manufacturers

The Art of Indigo Tie and Dye Manufacturing

Indigo tie and dye, an age-old textile tradition, holds a treasured place in the annals of fabric production. This vibrant art form, often seen in various cultures, is notable for its striking deep blue hues derived from the indigo plant. In recent years, there has been a resurgence of interest in indigo tie and dye, largely due to its eco-friendly appeal and the unique aesthetic it offers.

The manufacturing process of indigo tie and dye involves several intricate steps, each requiring a passionate artisan's attention to detail. First, fabric—commonly cotton or silk—is prepared through washing, which removes impurities and allows the dye to adhere better. Next, the fabric is tied, stitched, or folded in various patterns, depending on the desired design. This step is crucial, as it creates distinct resist areas that remain undyed when the fabric is submerged in the indigo dye bath.

The dye itself is created from the leaves of the indigo plant, which are harvested and fermented to extract the pigment. This natural dyeing method is not only sustainable but offers an array of shades, from deep navy to bright blue, depending on the dyeing technique and the number of dips the fabric undergoes. As the fabric emerges from the dye bath, it reveals the beauty hidden within the knots and folds, creating mesmerizing patterns.

indigo tie and dye manufacturers

In recent years, indigo tie and dye manufacturers have become more innovative, incorporating modern techniques and designs while remaining faithful to traditional methods

. Many now experiment with different materials, blending indigo dyeing with other textile arts such as block printing and screen printing. This fusion creates unique and contemporary pieces that appeal to a broader audience, thereby enhancing the market for indigo textiles.Moreover, the rise of sustainable fashion has significantly impacted indigo tie and dye manufacturers. As consumers become more conscious of their purchasing decisions, there is an increasing demand for environmentally friendly products. Many manufacturers are embracing sustainably sourced indigo and organic fabrics, ensuring that their production processes have minimal adverse effects on the environment.

In addition to aesthetic and ethical considerations, indigo tie and dye also offers economic benefits. It supports local artisans and traditional craftsmanship, contributing to communities' livelihoods. By promoting handmade products, manufacturers can preserve these cultural traditions while empowering artisans to showcase their skills on a global platform.

In conclusion, indigo tie and dye manufacturing is not just about fabric; it's about culture, sustainability, and creativity. As the world continues to embrace eco-friendly practices, the timeless appeal of indigo will remain relevant, inspiring future generations to explore this rich textile heritage. With each piece created, indigo tie and dye not only adds beauty to the fabric of the world but also weaves together stories, traditions, and the artistry of its makers.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

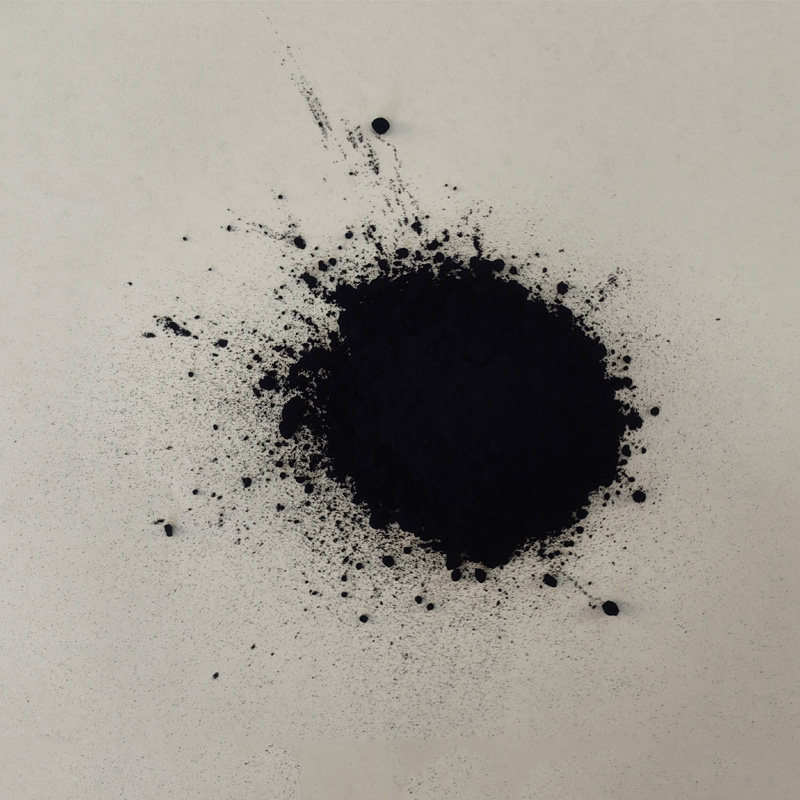

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.