Sulfur-Free Black Powder for High-Performance Applications and Clean Energy Solutions

The Rise of Sulfur-Free Black Powder A Revolutionary Shift in Explosives

In recent years, the demand for safer and cleaner explosives has led to significant innovations in the field of pyrotechnics and ammunition manufacturing. One of the most notable advancements in this sector is the development of sulfur-free black powder. Traditionally, black powder, often comprising saltpeter, charcoal, and sulfur, has been used for centuries in various applications, ranging from fireworks to firearms. However, the inclusion of sulfur has raised environmental and safety concerns, propelling the industry towards sulfur-free alternatives.

Understanding Black Powder Composition

Traditional black powder relies on three key ingredients potassium nitrate (saltpeter), charcoal, and sulfur. While this combination is effective, sulfur contributes to several disadvantages. It not only generates harmful sulfur dioxide gas upon combustion but also poses a risk of corrosion to weapons and storage facilities. Additionally, sulfur can create a more volatile mixture, making handling and storage more hazardous. Therefore, creating a formulation that eliminates sulfur while retaining performance has become a priority for manufacturers.

The Benefits of Sulfur-Free Black Powder

The primary advantage of sulfur-free black powder lies in its environmental impact. By removing sulfur from the composition, the production and combustion processes become significantly cleaner. This shift not only mitigates toxic gas emissions but also reduces the environmental footprint of explosive products. Furthermore, sulfur-free black powder tends to have a longer shelf life, as it is less susceptible to moisture absorption and chemical degradation, making it a preferred choice for commercial and military applications.

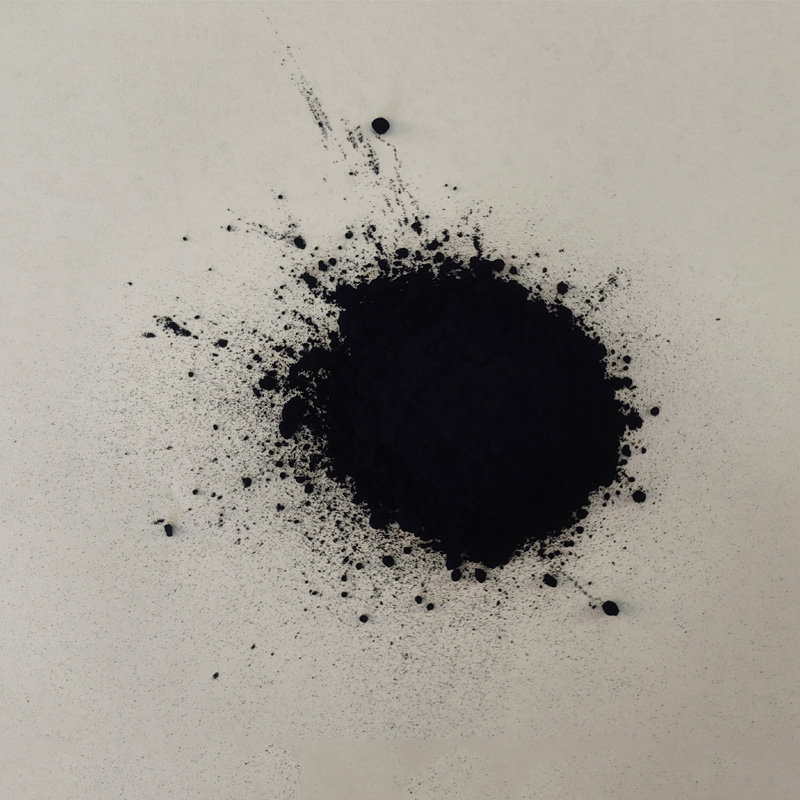

sulfur free black powder product

Moreover, the performance of sulfur-free black powder has proven to be comparable to that of traditional formulations. Although some may argue that the absence of sulfur affects the burn rate or energy output, advancements in chemistry and material science have led to the development of substitutes that enhance the explosive properties without compromising safety. These new formulations exhibit superior stability and reliability, ensuring their effectiveness in various uses, from recreational shooting to controlled explosives for mining operations.

Market Demand and Future Prospects

As environmental regulations become stricter across the globe, the demand for eco-friendly alternatives in the explosives industry has surged. Sulfur-free black powder is gaining traction not only among recreational users but also in military contracts that prioritize the safety of personnel and minimal environmental impact. The rising awareness of safety issues and the push for sustainable practices will likely accelerate the adoption of these new formulations.

Furthermore, research and development in this area are ongoing, with scientists exploring new materials and methods to enhance the performance of sulfur-free explosives. Innovations in nanotechnology and other advanced manufacturing techniques could lead to the creation of even more effective and versatile sulfur-free powder options.

Conclusion

The evolution towards sulfur-free black powder signifies a critical turning point in the explosive materials industry. As manufacturers respond to the challenges posed by traditional compositions, the resulting products not only ensure the safety of users and the environment but also maintain the high performance needed for various applications. With further advancements on the horizon, sulfur-free black powder could very well become the standard in explosives, leading to a cleaner and safer future in the world of pyrotechnics and ammunition manufacturing.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.