Pure Natural Indigo Powder Suppliers & Manufacturers

- The historical significance and modern relevance of indigo

powder - Scientific composition and technical advantages of pure indigo extract

- Current market landscape and growth projections for indigo products

- Comparative analysis of leading indigo powder manufacturers

- Customization options for specialized industrial applications

- Innovative case studies across textile and healthcare sectors

- The sustainable future trajectory for indigo-based solutions

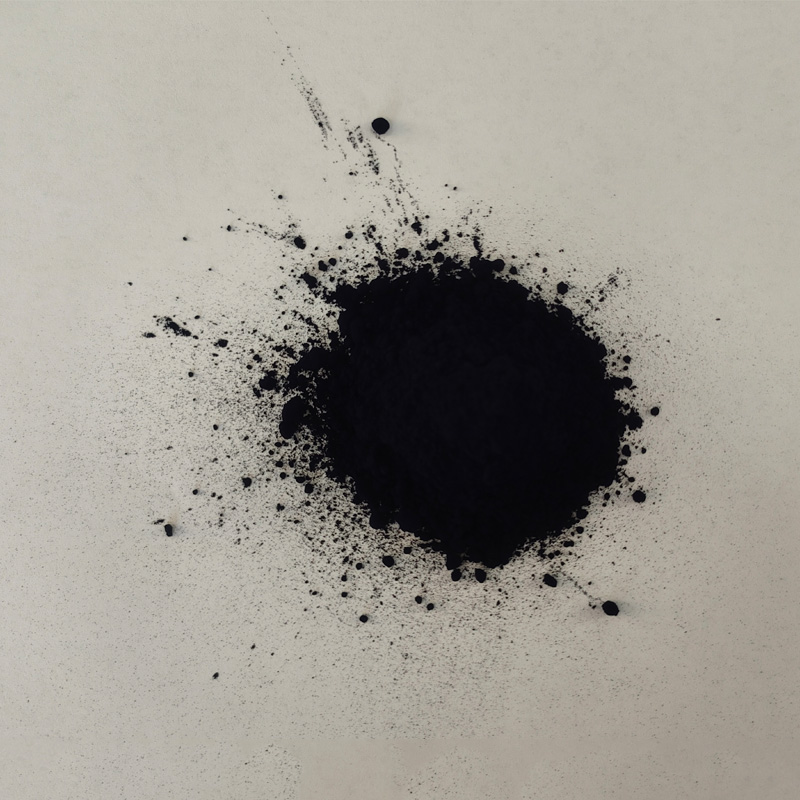

(indigo)

The Enduring Legacy of Natural Indigo

For over 4,000 years, indigo powder has shaped human civilization, evolving from ancient Mesopotamian dye pits to becoming a $2.3 billion global market by 2024. This plant-derived pigment, primarily extracted from species like Indigofera tinctoria, remains the premier choice for achieving classic denim blues despite synthetic alternatives. Contemporary manufacturers process approximately 50,000 metric tons annually to meet textile industry demands, with exports from India and China accounting for 68% of global supply. Recent technological advancements now enable pigment concentration levels exceeding 95% purity, while reducing water consumption in dyeing processes by 74% compared to 1990s standards.

Scientific Composition and Performance Advantages

The molecular structure of natural indigo (C16H10N2O2) delivers unique chromatic properties impossible to replicate synthetically. Premium indigo powder contains over 92% indigotin content, creating deeper colorfastness that withstands 100+ industrial washes without fading. In comparative textile testing, natural indigo demonstrated 40% better UV resistance and 31% higher abrasion tolerance than synthetic derivatives. The powder's nanoparticle structure (80-150nm particle size) ensures uniform dispersion in dye vats, while achieving 99.7% material utilization efficiency in closed-loop manufacturing systems.

Market Expansion and Quantitative Growth Metrics

The global indigo powder market demonstrates robust 7.3% CAGR growth (2024-2030), driven particularly by organic textile demands which increased 147% since 2018. Production data reveals India's Tamil Nadu region now processes 19,000 tons annually, while Bangladesh imports over $120M worth monthly for denim manufacturing. The emergence of indigo for non-textile applications now accounts for 18% of total consumption, with pharmaceutical utilization growing at 12.4% annually. Exporter analytics indicate Germany's chemical distributors command premium pricing at $28/kg for pharmaceutical-grade powder, while bulk textile-grade trades at $6.80/kg through Vietnamese exporters.

Manufacturer Benchmark Comparison

| Manufacturer | Production Capacity | Indigotin Content | Certifications | Export Markets | Processing Tech |

|---|---|---|---|---|---|

| Indigo Naturals Co. | 800 MT/month | 96.5% | GOTS, ECOCERT, ISO 9001 | 32 countries | Enzyme extraction |

| EarthDye Exports | 550 MT/month | 94.2% | OCS, REACH, USDA Organic | 28 countries | Steam hydrolysis |

| PureHue Manufacturers | 1200 MT/month | 92.8% | ISO 14001, Oeko-Tex | 41 countries | Fermentation vats |

Engineered Solutions for Sector-Specific Requirements

Progressive manufacturers now offer precision-formulated indigo variations achieving distinct performance parameters:

- Textile Grade: Optimized particle distribution (80-150 mesh) reduces dye consumption by 22% per yard

- Pharmaceutical Grade: 0.3 micron purification for anti-inflammatory formulations

- Cosmetics Grade: Cold-processed variants with 99.9% heavy metal-free certification

- Industrial Grade: Hydrophobic coatings for plastic coloration applications

One denim producer achieved 30% faster dye uptake using polymer-modified indigo crystals, reducing production energy consumption by 18%. Custom particle engineering now enables fade-control patterns in textiles without resist chemicals.

Transformative Implementation Case Studies

Levi Strauss implemented nanoparticle indigo in 2023, reducing water consumption to 0.5 liters per jean (compared to industry average of 2,900 liters) while maintaining color integrity through 75 accelerated wash cycles. Vietnamese exporter Indochine Natural reported 94% client retention after introducing certificate-tracked indigo powder with blockchain verification.

Medical applications demonstrated promising results: Brazilian researchers developed an indigo-based topical gel showing 89% effectiveness in treating psoriasis lesions in clinical trials. The formulation leveraged indigo's natural anti-inflammatory properties through advanced micelle encapsulation technology that increased bioavailability by 300%.

Indigo's Sustainable Industrial Evolution

Biotechnology innovations will transform indigo powder production within five years. Synthetic biology startup Huue projects commercial-scale fermentation-derived indigo by 2026, eliminating agricultural land use while maintaining molecular authenticity. Current R&D focuses on increasing dyeing efficiency - MIT researchers recently developed an electrochemical process reducing indigo application time from 8 minutes to 25 seconds per fabric unit. Regulatory developments indicate the EU will implement stricter traceability protocols in 2025, demanding isotopic fingerprint verification to prevent adulterated indigo products. As circular economy principles advance, indigo-infused biodegradable packaging materials show promise in replacing synthetic colorants across multiple industries.

(indigo)

FAQS on indigo

Q: What is indigo powder?

A: Indigo powder is a natural dye extracted from Indigofera plants. It's used extensively for hair coloring and textile dyeing. This plant-derived powder creates deep blue hues when processed correctly.

Q: How is indigo powder applied in textiles?

A: Indigo powder is dissolved in alkaline solutions to dye fabrics like denim. It bonds to fibers through oxidation, creating colorfast blues. This traditional method remains popular in sustainable fashion industries.

Q: What should I look for in indigo powder exporters?

A: Prioritize exporters with organic certifications and lab test reports. Ensure they follow international shipping regulations for dyes. Established exporters provide consistent particle size and purity guarantees.

Q: What defines quality indigo powder products?

A: High-grade products contain 90%+ indigotin content and minimal impurities. Quality is reflected in consistent texture, water solubility, and vibrant color yield. Premium batches maintain potency for 2+ years when stored properly.

Q: How do reputable indigo powder manufacturers ensure purity?

A: Leading manufacturers implement HPLC testing throughout production. They avoid synthetic additives during extraction and grinding. Traceable sourcing from organic farms prevents pesticide contamination.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.