oem dyeing indigo

The Art and Science of OEM Dyeing Indigo

Indigo dyeing has a rich heritage that dates back thousands of years, with its deep blue hue becoming synonymous with craftsmanship and quality. Today, the process of Original Equipment Manufacturer (OEM) dyeing indigo has transformed the textile industry, providing a unique combination of traditional techniques and modern manufacturing practices.

The Art and Science of OEM Dyeing Indigo

The indigo dyeing process typically starts with natural indigo, derived from the leaves of the indigofera plant, or synthetic indigo, which is widely used due to its consistency and vibrant color. The traditional method involves creating an indigo vat using the reducing agent, which allows the dye to dissolve. The fabric is then submerged in this vat, absorbing the dye gradually. As the fabric is exposed to oxygen upon removal from the vat, it develops its characteristic blue color.

oem dyeing indigo

One of the key advantages of OEM dyeing is the versatility it offers in terms of scale and customization. Brands can work closely with OEM manufacturers to create bespoke indigo-dyed fabrics that align with their design visions and consumer expectations. Whether it is for high-end fashion, sustainable apparel, or everyday denim, the OEM process can adapt to various aesthetic and functional specifications.

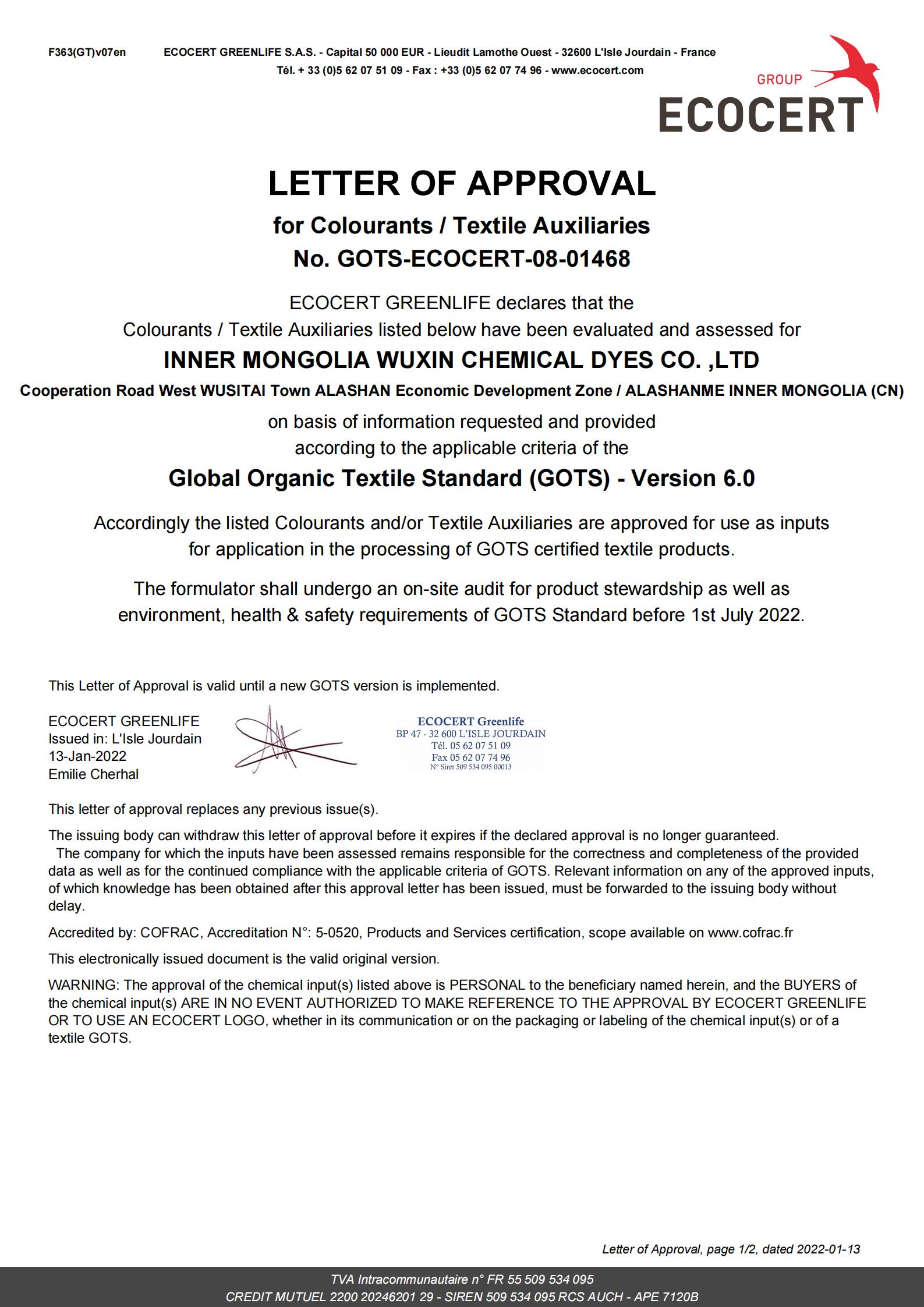

Moreover, with the growing consumer awareness of sustainability, many OEM dyeing manufacturers have started integrating eco-friendly practices. This includes using organic indigo, adopting water-saving dyeing techniques, and minimizing waste in the dyeing process. This shift not only caters to environmentally conscious consumers but also enhances the brand image.

An emerging trend within the OEM indigo dyeing landscape is the rise of digital printing technology. Brands are increasingly using digital methods to apply indigo dyes, allowing for intricate designs and patterns that were previously difficult to achieve. This innovation opens new avenues for creativity while maintaining the quality that indigo is known for.

In conclusion, OEM dyeing indigo represents a blend of tradition and innovation. It preserves the craftsmanship associated with indigo dyeing while embracing modern technological advancements. As the industry evolves, the collaboration between brands and OEM manufacturers will continue to shape the future of textile production, ensuring that the rich legacy of indigo remains vibrant and relevant in today’s market.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.