Notizia

-

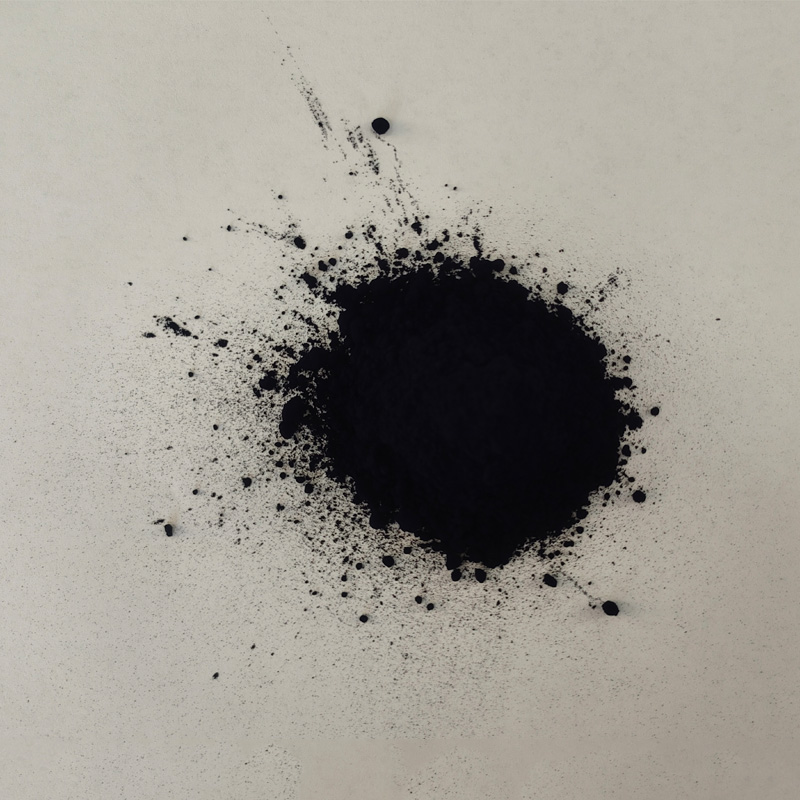

Sulfur black, so sulfur dyes themselves do not have dyeing ability for cotton. However, it has good dyeing properties for cotton by reducing the dye to leucosomes in aqueous solution of Sodium sulfide. The sulfur dye dyeing is carried out in Sodium sulfide solution.Per saperne di più

Sulfur black, so sulfur dyes themselves do not have dyeing ability for cotton. However, it has good dyeing properties for cotton by reducing the dye to leucosomes in aqueous solution of Sodium sulfide. The sulfur dye dyeing is carried out in Sodium sulfide solution.Per saperne di più -

Sulphur Black Dyes Sulphur Liquid Black Q

Sulfur dyes are insoluble in water but soluble in solution of alkaline reducing agents that convert them into their leuco form in which they have high affinity for fibre. Sulphur dyes liquid blacks are fully or partially reduced liquids.Per saperne di più -

Sulfur linkages are the integral part of chromophore in sulfur dyes

Sulfur dyes are the most commonly used dyes manufactured for cotton in terms of volume. They are inexpensive, generally have good wash-fastness, and are easy to apply. Sulfur dyes are predominantly black, brown, and dark blue.[1] Red sulfur dyes are unknown, although a pink or lighter scarlet color is availablePer saperne di più -

a preparation method for bromindigo dyestuff

is characterized in that: by the indigo oil of mirbane that is dissolved in, add bromizating agent, after reacting by heating 4-15h, with after organic solvent washing, filter to obtain filter cake, filter cake is with being drying to obtain product after hot wash.Per saperne di più -

A kind of preparation method of bromindigo dyestuff

The present invention relates to a kind of preparation method of dyestuff, be specifically related to a kind of preparation method of bromindigo dyestuff.Per saperne di più -

6,6'-Dibromoindigo is an organic compound with the formula (BrC6H3C(O)CNH)2. A deep purple solid, the compound is also known as Tyrian purple, a dye of historic significance.Per saperne di più

-

Indigo and Bromo Indigo. The Plant and Animal Kingdoms

Natural indigo was used since ancient times for dyeing textiles a blue color. Its structure became later known and has been synthesized by Adolf von Baeyer in 1880 in Germany who got the Nobel Prize in 1905. Bromo-indigo is a purple dye which was also used since ancient times by the Phoenicians in present day Lebanon and known as Tyrian purple obtained from the snails of Murex branderis in the Mediterranean Sea.Per saperne di più -

sulphur black-How did you first become interested in indigo and natural dyes in general?

Bailiwick Blue farm, is located in Gélé Vinery, on the west coast of Guernsey, within an old Guernsey Frampton commercial greenhouse, built in the 1960s. The term “vinery” is a colloquialism stemming from the commercial Guernsey grape and tomato growing industry.Bailiwick Blue has been in residence since 2017. It was originally a small project just to grow, make and dye with indigo for personal use, sharing the space with other creatives. In 2019, Gélé Vinery became home to Bailiwick Blue and many Persicaria Tinctoria (Japanese Indigo) plants.The dye plant varieties have increased over the years. Indigo grows in half of the working footprint. Madder, marigold, dyer’s chamomile, coreopsis, scabiosa, sulphur cosmos and Hopi sunflowers are also part of the Bailiwick Blue growing arena.Per saperne di più -

indigo granular-How to Make Organic Indigo Vat Tutorial

My first forays into natural dyeing began with the vibrant blue dye of indigo. Indigo is the name given to the dye that comes from plants (of which there are many species) containing the indican compound that produces an incredible blue dye. Used throughout Asia, South America & Africa, indigo has a rich and vibrant history & is one of the oldest know natural dyes used by man. The process of dyeing with indigo is unlike most other natural colourants, setting it apart from many other dyes. I am going to show you how to make a simple indigo vat based on a recipe by French chemist, Micheal Garcia known as the 1-2-3 vat, using as the name suggests three ingredients which are indigo – Lime – Fructose.Per saperne di più -

indigo-Hot vs Cold indigo extraction from fresh Japanese Indigo leaves

Currently the main method of indigo extraction in use on internet Facebook pages is the 2 -3 day long soak in water. I believe this was the main method used commercially in the days before synthetic indigo wiped out the western market for natural indigo. Originally used to extract indigo from Indigofera tinctoria it is still used for small scale production in South Asia. The method is now used for Japanese indigo presumably because the traditional Japanese Method of composting the leaves is too large scale and time consuming for craft dyers. So it has been with some bafflement that I’ve seen the rise of this soaking method as I have always followed the Jenny Dean method which is even quicker.Per saperne di più -

Indigo, or indigotin, is a dyestuff originally extracted from the varieties of the indigo and woad plants. Indigo was known throughout the ancient world for its ability to color fabrics a deep blue. Egyptian artifacts suggest that indigo was employed as early as 1600 b.c. and it has been found in Africa, India, Indonesia, and China.The dye imparts a brilliant blue hue to fabric. In the dying process, cotton and linen threads are usually soaked and dried 15-20 times. By comparison, silk threads must be died over 40 times. After dying, the yarn may be sun dried to deepen the color. Indigo is unique in its ability to impart surface color while only partially penetrating fibers. When yarn died with indigo is untwisted, it can be seen that the inner layers remain uncolored. The dye also fades to give a characteristic wom look and for this reason it is commonly used to color denim. Originally extracted from plants, today indigo is synthetically produced on an industrial scale.Per saperne di più

Indigo, or indigotin, is a dyestuff originally extracted from the varieties of the indigo and woad plants. Indigo was known throughout the ancient world for its ability to color fabrics a deep blue. Egyptian artifacts suggest that indigo was employed as early as 1600 b.c. and it has been found in Africa, India, Indonesia, and China.The dye imparts a brilliant blue hue to fabric. In the dying process, cotton and linen threads are usually soaked and dried 15-20 times. By comparison, silk threads must be died over 40 times. After dying, the yarn may be sun dried to deepen the color. Indigo is unique in its ability to impart surface color while only partially penetrating fibers. When yarn died with indigo is untwisted, it can be seen that the inner layers remain uncolored. The dye also fades to give a characteristic wom look and for this reason it is commonly used to color denim. Originally extracted from plants, today indigo is synthetically produced on an industrial scale.Per saperne di più -

indigo granular-Is Natural Indigo More Sustainable than Synthetic?

Continuing our series of mythbusting and clarifying, we now turn our eye toward another essential ingredient for denim: indigo dye. Conscious consumers have a tendency to romanticize the natural stuff that is produced from plants, swooning over its long history of use in traditional and artisan fashion production, while turning up their noses (in theory) at modern synthetic dyes that make churning out millions of $20 fast fashion jeans possible.Per saperne di più