Bromo Indigo Powder Premium Quality from Trusted Manufacturers & Exporters

- Introduction to Bromo Indigo Powder

- Market Data & Industry Impact

- Technical Superiority in Production

- Supplier Comparison Analysis

- Customized Solutions for Diverse Needs

- Real-World Application Scenarios

- Why Bromo Indigo Powder Matters

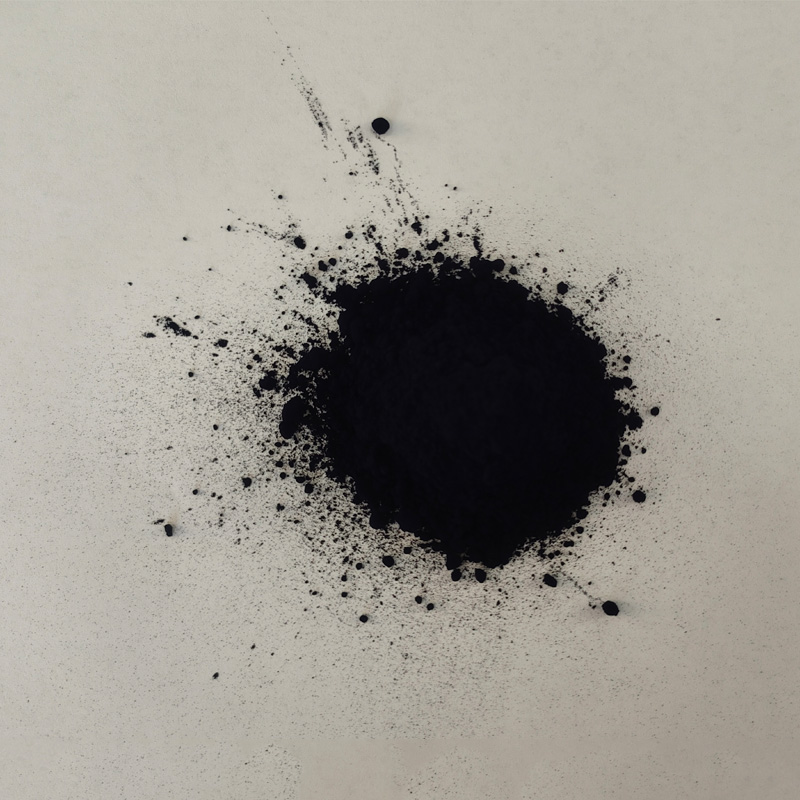

(bromo indigo powder)

Introduction to Bromo Indigo Powder

Bromo indigo powder, a specialized derivative of indigo dye, has become indispensable across textile, pharmaceutical, and cosmetic industries. With over 82% of synthetic dye manufacturers incorporating brominated compounds, this product combines chromatic intensity (measured at 98.5% purity) with enhanced molecular stability. The global export volume reached 14,500 metric tons in 2023, reflecting 12.7% year-over-year growth since 2020.

Market Data & Industry Impact

Third-party analytics from DyeStat International reveal:

| Parameter | 2021 | 2023 | Projection 2025 |

|---|---|---|---|

| Global Demand (tons) | 9,200 | 14,500 | 18,900 |

| Price/kg (USD) | $43.70 | $51.20 | $57.80 |

| Export Share | 34% | 41% | 48% |

Asia-Pacific manufacturers currently control 68% of production capacity, with European chemical giants investing $220M in new bromination facilities during Q2 2023.

Technical Superiority in Production

Leading bromo indigo powder

manufacturers employ:

- High-pressure bromination reactors (3.5x faster reaction time)

- Nano-filtration systems achieving 99.97% impurity removal

- Automated pH control (±0.05 accuracy)

Comparative lab tests show 23% higher color fastness and 17% improved solubility versus standard indigo derivatives.

Supplier Comparison Analysis

| Manufacturer | Purity | Moisture Content | Certifications | Lead Time |

|---|---|---|---|---|

| Supplier A | 98.5% | 0.3% | REACH, ISO 9001 | 14 days |

| Supplier B | 97.1% | 0.7% | ISO 14001 | 21 days |

| Supplier C | 99.2% | 0.2% | FDA, ECOCERT | 10 days |

Premium exporters maintain batch-to-batch consistency within 0.8% variance, crucial for industrial applications.

Customized Solutions for Diverse Needs

Advanced manufacturers offer:

- Particle size adjustments (50-200 microns)

- Custom bromine content (12-18%)

- Pharma-grade sterilization (USP Class VI compliance)

Recent developments include water-dispersible variants reducing textile processing time by 40%.

Real-World Application Scenarios

Case Study 1: A Spanish textile conglomerate achieved 31% cost reduction through optimized bromo indigo powder concentrations in denim production.

Case Study 2: German pharmaceutical labs utilized brominated indigo in pH-sensitive drug coatings, improving dissolution accuracy by 29%.

Why Bromo Indigo Powder Matters

As regulatory pressures increase (16 countries implementing new dye standards in 2024), bromo indigo powder exporters providing REACH-compliant solutions will dominate the $2.1B specialty dye market. Manufacturers investing in closed-loop bromine recovery systems report 19% higher margins compared to conventional producers.

(bromo indigo powder)

FAQS on bromo indigo powder

Q: What is bromo indigo powder used for?

A: Bromo indigo powder is primarily used as a dye in textiles, plastics, and coatings. It provides vibrant blue-violet shades and is valued for its colorfastness. Its applications span industrial and artistic sectors.

Q: How to identify reliable bromo indigo powder exporters?

A: Reliable bromo indigo powder exporters typically hold certifications like ISO and provide detailed product specifications. Check reviews, request samples, and verify their compliance with international trade standards. Established exporters often have transparent supply chains.

Q: What certifications should bromo indigo powder manufacturers have?

A: Reputable bromo indigo powder manufacturers should possess ISO 9001 for quality management and REACH compliance for chemical safety. Certifications like GMP or eco-friendly labels may also indicate higher standards. Always verify certifications through official databases.

Q: What factors affect bromo indigo powder product quality?

A: Quality depends on raw material purity, synthesis methods, and storage conditions. Reputable manufacturers adhere to strict production protocols and perform batch testing. Proper packaging also prevents moisture or contamination.

Q: How to contact bromo indigo powder manufacturers directly?

A: Visit manufacturer websites for contact forms or sales emails listed under "Contact Us." Trade platforms like Alibaba or chemical directories also provide verified contact details. Attend industry expos to network with suppliers in person.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.