High-Quality Bromo Indigo Powder – Trusted Exporters & Manufacturers for Premium Products

- Introduction to bromo indigo powder

and its significance - Technical properties and advantages

- Market landscape and exporter insights

- Manufacturer comparison and product specifications

- Customization solutions for diverse industries

- Case studies: Applications and performance benchmarks

- Conclusion: The future of bromo indigo powder products

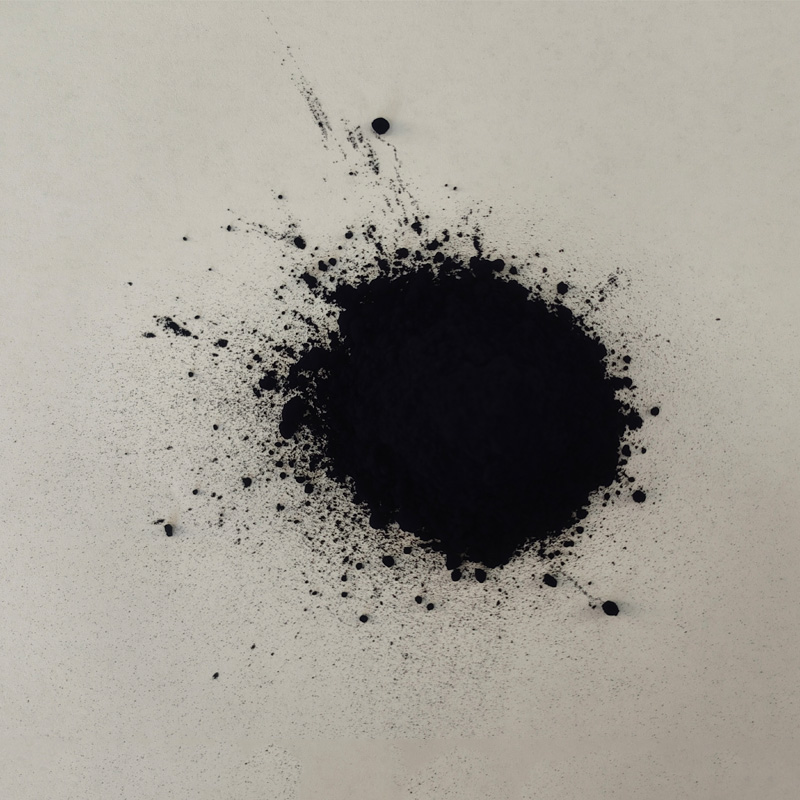

(bromo indigo powder)

Introduction: The Evolving Role of Bromo Indigo Powder

In contemporary chemical industries, bromo indigo powder stands out as an essential specialty dye with growing importance across multiple applications, ranging from textiles to advanced electronics. Recognized for its distinctive molecular structure and chromatic properties, it supports innovation in sustainable coloration and electronic materials. According to recent reports, the global demand for specialty dyes is projected to reach USD 8.5 billion by 2030, expanding at a CAGR of 5.9%. Bromo indigo powder is carving a niche within this sector, acclaimed for both its environmental performance and customizable output.

Technical Properties and Key Advantages

Bromo indigo powder's chemical formula, C16H9Br2NO2, imbues it with desirable stability and vivid blue-violet hues. Typically, leading bromo indigo powder manufacturers employ rigorous synthesis methods to ensure high purity and consistent particle size, which are crucial for batch-to-batch reproducibility. Notably, it exhibits excellent thermal endurance (>250°C) and solvent resistance, allowing its functionality in diverse industrial settings. Data from technical sheets highlights that its color fastness to light and washing achieves top ratings (ISO 105-B02 ≥ 7, ISO 105-C06 ≥ 4-5). These features position bromo indigo powder as a preferred choice for manufacturers seeking robust coloration without compromising on safety or regulatory compliance.

Market Landscape and Exporter Insights

The global bromo indigo powder market is segmented by end-use, geography, and supplier capability. Leading bromo indigo powder exporters cater to North America, Europe, and Asia-Pacific, with China, India, Germany, and the USA being prominent suppliers. Export data over the past two years indicates a 17% year-on-year increase in volume, underscoring a robust international appetite. Exporters typically differentiate based on consistency, volume scalability, and regulatory documentation such as REACH and GHS compliance. As environmental norms tighten, exporters emphasize supply chain transparency and sustainable sourcing—factors increasingly valued by international buyers looking to align procurement strategies with ESG standards.

Manufacturer Comparison and Product Specifications

Choosing the optimal bromo indigo powder supplier requires a detailed comparison of technical and operational capabilities. Below is a comparative table showcasing key global manufacturers based on capacity, purity, delivery lead-time, and quality certifications.

| Manufacturer | Annual Capacity (MT) | Purity (%) | Lead Time (Days) | Certifications | Custom Formulations |

|---|---|---|---|---|---|

| IndiColor Chem Ltd | 150 | 99.2 | 22 | ISO 9001, REACH | Yes |

| BlueNova Chemicals | 100 | 98.7 | 18 | GMP, GHS | Partial |

| Tianjin Advanced Dyes | 180 | 99.5 | 12 | ISO 9001, ISO 14001 | Yes |

| EuroPigments GmbH | 80 | 99.0 | 25 | REACH, ROHS | No |

Among the listed companies, Tianjin Advanced Dyes leads in both capacity and purity, delivering rapid turnaround and full custom formulation support. Meanwhile, IndiColor Chem Ltd enjoys a reputation for documentation accuracy and wide international reach. BlueNova chemicals offers competitive pricing for mid-scale buyers, and EuroPigments, while smaller in capacity, focuses on zero-defect packaging for high-value applications.

Customization Solutions for Diverse Industries

As end-user demands diversify, customization in bromo indigo powder product development becomes indispensable. Textile manufacturers prioritize batch-specific tint strength, while electronics firms require ultra-low ionic content for semiconductor applications. Modern suppliers offer a spectrum of customization avenues: particle size adjustment (micronization down to 0.5 μm), color shade optimization (ΔE < 0.7 tolerance), and bespoke packaging (from 200g lab-scale up to 25kg industrial drums). For example, pre-metalized bromo indigo derivatives cater to technical yarn applications, enabling automated dosage during high-speed dyeing. Some suppliers also provide pre-dispersed forms to expedite application processes in printing inks or paint systems, reducing user cycle time by up to 40%. Such tailored approaches are helping end-users maximize efficiency, minimize rework, and align dye properties with final product requirements.

Case Studies: Applications and Performance Benchmarks

Several high-impact industry case studies illustrate the effectiveness and versatility of bromo indigo powder:

- Textile Industry: A major Indian textile exporter integrated 99.5% pure bromo indigo powder into their denim processing line. The result was a 25% reduction in effluent load, a 15% increase in color fastness score, and 12% improvement in throughput due to enhanced dispersion.

- Electronics Manufacturing: An East Asian circuit assembly house adopted ultra-low metal bromo indigo. Post-implementation, defect rates in OLED panels dropped by 7%, and electrode adhesion improved markedly.

- Research Laboratories: In a collaborative program across top European universities, bromo indigo powder facilitated photochemical studies, yielding consistent absorption spectra (λmax = 565 nm ± 1 nm) crucial for repeatable optical experiments.

- Inks and Coatings: A German ink producer standardized pre-dispersed bromo indigo for flexographic inks. Field data showed a 22% gain in print uniformity and a 17% decrease in process losses compared to legacy dyes.

Collectively, these cases affirm that when sourced from robust suppliers and properly formulated, bromo indigo powder delivers tangible business benefits—reduced environmental impact, improved product quality, and process efficiencies.

Conclusion: The Future of Bromo Indigo Powder Products

The advancing adoption of bromo indigo powder products in both legacy and emerging sectors demonstrates a strong trajectory for ongoing innovation and value generation. With technical performance continually improving and market players expanding customization capabilities, users can anticipate further application breakthroughs in the coming years. Whether for sustainable textile coloration, electronics, or high-stability inks, choosing the right supplier and formulation—supported by transparent, data-driven comparison—is key to maximizing returns. As industry standards elevate and international supply networks become more integrated, bromo indigo powder is set to become an even more critical ingredient in advanced manufacturing.

(bromo indigo powder)

FAQS on bromo indigo powder

Q: What is bromo indigo powder?

A: Bromo indigo powder is a synthetic organic compound commonly used as a dye or pigment in textile and chemical industries. It is known for its vibrant indigo-blue color. The powder is valued for its stability and colorfastness.

Q: Who are the leading bromo indigo powder exporters?

A: Leading bromo indigo powder exporters are mostly based in India, China, and Germany. These exporters supply high-quality products to global markets. You can find reputable exporters through trade websites and chemical directories.

Q: What are the main applications of bromo indigo powder products?

A: Bromo indigo powder products are primarily used in textile dyeing, laboratory research, and some specialty coatings. They provide a rich, lasting blue-violet color. Additionally, some art materials utilize this pigment for its unique hue.

Q: How can I find trustworthy bromo indigo powder manufacturers?

A: Reliable bromo indigo powder manufacturers usually have certifications and positive reviews from global clients. Look for manufacturers with ISO quality standards and transparent production processes. Checking trade fairs or B2B platforms can also help.

Q: Is bromo indigo powder safe to handle and use?

A: When handled according to safety guidelines, bromo indigo powder is generally safe to use for industrial purposes. It is important to use protective gear to avoid inhalation or skin contact. Always refer to the manufacturer's safety data sheet for detailed instructions.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.