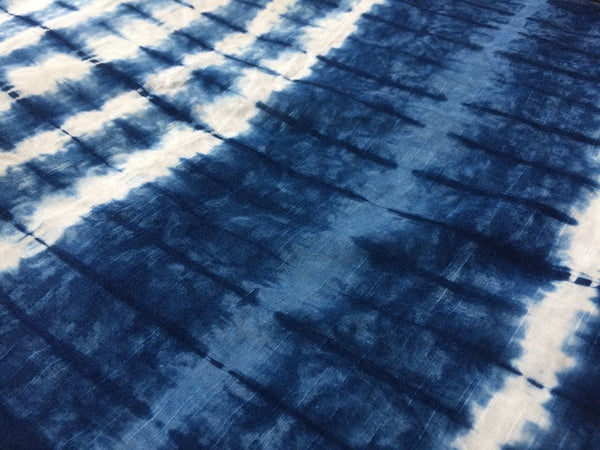

light indigo color manufacturers

From an expert perspective, the success of integrating Sulphur Black 200 into manufacturing processes depends significantly on the technique and craftsmanship of the workers involved. Companies striving for excellence in their final product should prioritize training their team to adeptly manage the dyeing process. Trustworthy suppliers also play a crucial role in the supply chain, ensuring that they deliver high-quality and authentic sulphur dyes. Working with renowned suppliers secures the consistency and effectiveness of the dye, thereby enhancing the overall credibility of the finished textile product. Real-world experiences speak volumes about the practicality of Sulphur Black 200 as a tactical solution to achieve superior black hues. Industry challenges such as color fading, variability in penetration, or fiber compatibility are mitigated through meticulously planned dyeing processes, supervised by seasoned professionals who always adhere to high standards. In conclusion, Sulphur Black 200 remains a staple in the textile dyeing industry due to its proven effectiveness, affordability, and colorfastness. Positioned as a critical component in manufacturing aesthetically appealing and durable products, its adoption is backed by decades of expertise and authoritative testimonials. Trust in this product is inherent, as it consistently validates the industry's demands for quality and reliability.

-

Thermal Stability Analysis of Bromo Indigo Pigments

NewsJun.06,2025

-

Sulphur Black Dye Oxidation Process Optimization

NewsJun.06,2025

-

Lightfastness Testing of Bromo Indigo Dyed Denim

NewsJun.06,2025

-

Granule Size Distribution and Jeans Color Uniformity

NewsJun.06,2025

-

Gradient Dyeing Methods with Indigo Blue Granules

NewsJun.06,2025

-

Dyeing Temperature Effects on Sulphur Black Color Fastness

NewsJun.06,2025

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.