sulphur dyes factories

The Evolving Landscape of Sulphur Dyes Factories

In the world of textile manufacturing, dyes play a crucial role in defining color, vibrancy, and quality of finished products. Among the myriad types of dyes available, sulphur dyes have carved a significant niche due to their unique properties and versatility. The sulphur dyeing process has evolved over the decades, leading to the establishment of specialized factories dedicated to producing these dyes. This article explores the importance of sulphur dyes, the manufacturing process, and the future trends in sulphur dye factories.

Understanding Sulphur Dyes

Sulphur dyes are a class of water-insoluble dyes derived from organic compounds. They are particularly favored for dyeing cellulose fibers like cotton and are known for their high lightfastness, washfastness, and ability to produce deep colors. These dyes are typically employed in a variety of applications, from apparel to home furnishings, making them a staple in the textile industry.

The unique characteristics of sulphur dyes stem from their chemical structure. They are generally applied in a reduced, water-soluble form, allowed to penetrate the fabric, and subsequently oxidized to their insoluble form, resulting in vivid and durable colors. This two-step dyeing process contributes to the complexity of sulphur dye production and necessitates the establishment of specialized manufacturing facilities.

Manufacturing Process of Sulphur Dyes

The production of sulphur dyes involves several key steps, each of which is essential in ensuring high-quality output. First, the manufacturing process begins with the synthesis of the dye compounds, often involving intricate chemical reactions that take place in controlled environments. This stage requires skilled chemists and stringent safety measures, given the potential hazards involved in handling raw materials and intermediate products.

sulphur dyes factories

Once the dyes are synthesized, they must be processed into a form suitable for dyeing applications. This typically includes drying, grinding, and sometimes granulating the dyes to achieve desired physical properties. Quality control is paramount at this stage, as inconsistencies can significantly impact the dyeing process and the final product quality.

Furthermore, sustainable practices are becoming increasingly important in the sulphur dye manufacturing process. Many factories are adopting eco-friendly technologies and methods to minimize waste and reduce the environmental footprint of their operations. This shift reflects the growing awareness of sustainability within the textile industry and the demand for environmentally responsible manufacturing practices.

Future Trends in Sulphur Dye Factories

Looking ahead, it is clear that the sulphur dye industry is poised for transformation. Innovations in technology, such as the use of advanced spectrophotometry for color matching and automated dyeing machines, are changing the landscape of dye production. These advancements not only improve efficiency and reduce labor costs but also enhance the precision of dye application.

Moreover, as consumers become more environmentally conscious, there is a rising demand for eco-friendly dyes. This necessitates a shift towards more sustainable and biodegradable options within the sulphur dye sector. Companies are investing in research and development to create less harmful dye formulations and more efficient dyeing processes that conserve water and energy.

Global textile regulations are also evolving, pushing manufacturers to adhere to stricter safety and environmental standards. This will likely further influence the operational practices within sulphur dye factories, ensuring they align with international expectations.

In conclusion, sulphur dyes continue to be a vital component of the textile industry, with specialized factories playing a crucial role in their production. As the industry adapts to technological advancements and increased sustainability demands, sulphur dye factories will likely evolve, embracing new methods and practices that prioritize effectiveness without compromising environmental responsibility. This transformation promises to enhance the quality and appeal of textile products while meeting the growing expectations of consumers and regulators alike.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

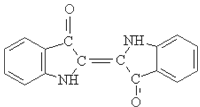

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.