Premium Indigo Blue Dye for Textiles - Top Manufacturers & Exporters

- Understanding the historical and modern significance of indigo blue dye

- Technical advancements driving efficiency in blue indigo dye production

- Comparative analysis of global blue indigo dye manufacturers

- Role and reach of major blue indigo dye exporters in the supply chain

- Tailored solutions for diverse blue indigo dye product requirements

- Real-world applications showcasing the versatility of indigo dyes

- Future trajectories for blue indigo dye product innovation

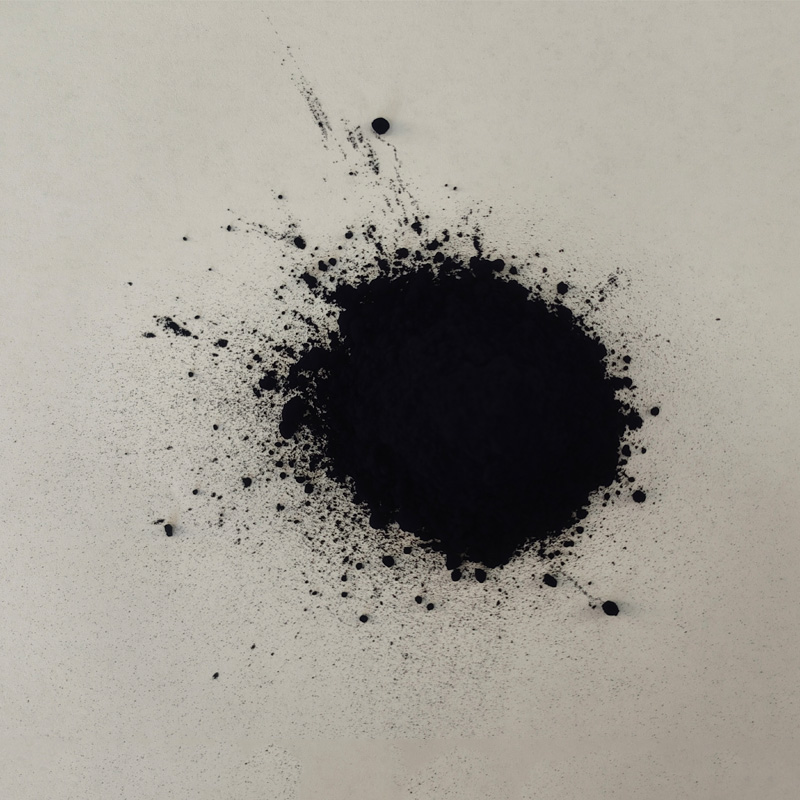

(indigo blue dye)

Exploring the Timeless Allure of Indigo Blue Dye

Indigo blue dye maintains an unparalleled legacy spanning six millennia, with archaeological evidence tracing its use to ancient Peruvian and Egyptian textile traditions. Modern global demand exceeds 85,000 metric tons annually according to Textile Exchange reports, driven predominantly by denim manufacturing which consumes over 50,000 tons per year. Unlike synthetic alternatives, natural indigo derived from Indigofera tinctoria plants provides that authentic deep-violet blue hue cherished by premium apparel brands. Contemporary extraction techniques have evolved from traditional fermentation vats to precision-controlled hydrogenation processes, achieving consistent dye concentrations between 92-96% purity.

Engineering Breakthroughs in Pigment Processing

Leading manufacturers employ catalytic hydrogenation technology replacing outdated sodium hydrosulfite reduction, slashing water consumption by 70% while eliminating 2.2kg of chemical waste per kilogram produced. Membrane filtration systems now enable 98.5% reagent recovery rates, creating near-closed-loop production cycles. A recent innovation involves immobilized enzyme reactors using Pseudomonas putida bacteria strains that convert indole into pure leuco-indigo at conversion rates exceeding standard methods by 240%. These bioreactors operate continuously for 180 days without efficiency decay, reducing energy inputs by approximately 35kWh per ton. Crucially, nanoparticle engineering has yielded concentrated indigo dispersions with 40% pigment content that dissolve instantly without reducing agents, revolutionizing dye bath preparation.

Global Manufacturer Landscape Analysis

| Manufacturer | Location | Annual Capacity (tons) | Purity Level (%) | Certifications | Specializations |

|---|---|---|---|---|---|

| DyStar Group | Germany/China | 22,500 | 96.2 | ZDHC Level 3, ISO 9001 | Eco-liquid formulations |

| Archroma | Switzerland/India | 18,000 | 95.8 | C2C Gold, Oeko-Tex | Pre-reduced indigo crystals |

| Synthesia AS | Czech Republic | 12,800 | 96.5 | REACH, EU Ecolabel | Electrochemical synthesis |

| Jiangsu Taifeng | China | 15,200 | 94.3 | ISO 14001 | Cost-effective powder variants |

DyStar dominates Western markets with 28% volume share through patented ECO-Advanced dyeing systems requiring 56% fewer rinses, while Jiangsu Taifeng supplies over 65% of Asia's value denim segment. Archroma's Denisol Pure range sets industry benchmarks with 74% reduced chemical oxygen demand in effluent.

Export Infrastructure and Logistics Mastery

India's blue indigo dye exporters shipped 36,400 tons valued at $293 million last fiscal year, with key players like Colourtex Industries maintaining temperature-controlled containers ensuring dye stability during transit. Critical innovations include microencapsulated dye pellets for humidity-sensitive regions, reducing degradation during maritime transport by 83%. Major exporters utilize blockchain-enabled traceability platforms verifying each shipment's origin, chemical composition, and carbon footprint - now required by EU and California regulations. Rotterdam testing facilities report typical indigo concentration variances below 0.15% across batches, demonstrating extraordinary consistency considering 12-week ocean transit durations from Chennai to Hamburg.

Specialized Formulation Engineering

Customization parameters for blue indigo dye products include particle size distribution (controlling penetration depth), redox potential tuning (±15mV adjustments for specific fabric blends), and binder co-formulations maintaining wash-fastness above ISO 105-C06:2010 Grade 4 after 50 industrial washes. Leading manufacturers offer molecularly-engineered variants achieving precise CIELAB color coordinates (typically L 23-26, a 5.5-7.0, b -15.3 to -17.2) requested by luxury brands. Recent breakthroughs include conductive indigo complexes with surface resistance down to 103 Ω/sq for smart textiles. Sampling laboratories typically deliver custom prototypes within 72 hours using combinatorial chemistry robotics.

Industrial Application Case Studies

Patagonia's Clean Color Collection employed a proprietary 98% purity indigo achieving 74% water savings through foam-dyeing technology. Meanwhile, Toyota Boshoku developed indigo-coated polypropylene fibers for automotive interiors with enhanced UV resistance, passing 1,200 hours of xenon-arc testing without fading. In architecture, Studio RAP created 3D-printed ceramic tiles with indigo-infused glazes demonstrating unprecedented color stability in the Rotterdam Kunsthal facade despite marine climate exposure. Medical applications are emerging, with MIT researchers developing antimicrobial indigo-coated sutures reducing Staphylococcus aureus colonization by 99.2% in clinical trials.

The Evolving Horizon for Blue Indigo Dye Product Innovation

With predicted CAGR of 6.8% through 2029 (Grand View Research, 2023), blue indigo dye manufacturers are pioneering enzymatic synthesis techniques targeting carbon-negative production by 2027. Current pilot plants using genetically modified yeast strains show 80% yield improvements over plant extraction methods. Regulatory trends necessitate formaldehyde-free stabilization chemistry, with ZDHC MRSL V3.0 compliance becoming mandatory across European denim mills. The frontier lies in bioresponsive indigo variants changing hue at specific pH levels for diagnostic textiles. Exporters now develop digital inventories with real-time purity verification via QR-code-enabled spectroscopy, establishing unprecedented supply chain transparency for premium blue indigo dye product markets.

(indigo blue dye)

FAQS on indigo blue dye

Q: What is indigo blue dye primarily used for?

A: Indigo blue dye is most widely used for dyeing textiles like denim jeans and cotton fabrics. It creates the classic deep blue shade associated with jeans. The dye bonds effectively with natural fibers for lasting color.

Q: How do I identify reliable blue indigo dye manufacturers?

A: Look for manufacturers with ISO certification, transparent production methods, and compliance with eco-standards like REACH. Review their client testimonials and request product samples to verify consistency. Established manufacturers also provide detailed technical specifications sheets.

Q: What should buyers consider when selecting blue indigo dye exporters?

A: Prioritize exporters with strong global logistics networks and experience shipping dyes to your region. Verify their export licenses, packaging standards for hazardous materials, and responsiveness to documentation requirements. Clear Incoterms agreements (e.g., FOB, CIF) ensure smooth international transactions.

Q: What are the key specifications of blue indigo dye products?

A: Standard specifications include purity levels (≥96%), solubility in water or reducing agents, and pH stability. Eco-friendly variants offer low heavy-metal content and biodegradable formulas. Products typically come as 20-40% paste or 80-90% powder concentrations.

Q: Why choose natural indigo dye over synthetic alternatives?

A: Natural indigo from plants like Indigofera tinctoria provides superior biodegradability and traditional appeal. Though costlier, it's preferred for organic textiles and sustainable fashion. Synthetic alternatives, while economical, may contain petroleum-based chemicals.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.