sulphur black 1 manufacturers

Overview of Sulphur Black 1 Manufacturers

Sulphur Black 1, a versatile synthetic dye, plays a crucial role in textile, leather, and other industries, providing a deep, rich black color. Its importance extends beyond aesthetics, as it is utilized in various applications due to its excellent fastness properties and cost-effectiveness. This article explores the landscape of Sulphur Black 1 manufacturers, highlighting their processes, quality control measures, and the challenges they face in the market.

Understanding Sulphur Black 1

Sulphur Black 1 is a type of sulfur dye that is water-insoluble but can dissolve in alkaline solutions. It is primarily used for dyeing cotton, wool, and other cellulose fibers, as well as for leather. This dye is favored for its high color strength, lightfastness, and wash fastness, making it ideal for products that undergo frequent washing or exposure to sunlight.

Due to its composition, Sulphur Black 1 provides a stark contrast to lighter colors, making it a preferred choice for denim production, print fabrics, and leather goods. The dyeing process typically involves reducing the dye in an alkaline solution, allowing it to penetrate the fibers before being oxidized to bring out the desired black color.

Key Manufacturers and Their Processes

The Sulphur Black 1 manufacturing process requires precise chemistry and rigorous quality control to ensure high standards. Leading manufacturers invest heavily in R&D to improve their production methods and develop eco-friendlier alternatives. Companies such as Huntsman Corporation, DyStar, and Archroma are some of the prominent players in this market.

1. Huntsman Corporation Recognized for its innovation, Huntsman focuses on producing high-quality dyes, including Sulphur Black 1, while adhering to environmental sustainability. They utilize advanced chemical engineering techniques to enhance dye performance and reduce environmental impact.

2. DyStar A global textile chemicals supplier, DyStar offers a comprehensive range of dye solutions, including Sulphur Black 1. Their commitment to quality is evident in their stringent testing protocols, ensuring that each batch adheres to international safety and environmental standards.

3. Archroma One of the industry leaders in color and specialty chemicals, Archroma emphasizes sustainable practices in dye production. They are constantly exploring alternative raw materials and processes that minimize wastewater and emissions.

sulphur black 1 manufacturers

Quality Control Measures

Quality control in the manufacturing of Sulphur Black 1 is critical. Manufacturers conduct extensive testing at various stages, from raw materials to finished products. This includes

- Raw Material Inspection Ensuring that the raw materials meet specific standards for purity and composition. - In-Process Testing Monitoring chemical reactions during production to maintain consistent performance and prevent defects. - Final Product Testing Evaluating color fastness, dye strength, and solubility to ensure compliance with industry standards.

Additionally, manufacturers often implement ISO certifications, which are indicative of their commitment to maintaining high-quality standards in their production processes.

Market Dynamics and Challenges

The demand for Sulphur Black 1 is influenced by several factors, including global trends in textile manufacturing, consumer preferences for sustainable dyes, and regulatory changes regarding chemical use. While the market for this dye remains strong, manufacturers face challenges such as

- Environmental Regulations Stricter environmental laws are driving manufacturers to invest in cleaner production technologies, which can increase costs. - Competition The rise of alternative dyes and new entrants in the market increases competition, compelling established manufacturers to innovate and maintain customer loyalty. - Supply Chain Disruptions Global events can impact the availability of raw materials, causing delays in production and affecting overall supply.

Conclusion

As Sulphur Black 1 continues to be a staple in dyeing and coloration, manufacturers must balance quality, sustainability, and cost-effectiveness. The industry's key players stand at the forefront, innovating while adhering to environmental practices that not only benefit their businesses but also contribute to a greener planet. In this dynamic landscape, quality assurance and adherence to regulatory standards will be critical for the future of Sulphur Black 1 manufacturing. As they navigate through these challenges, manufacturers will play an essential role in shaping sustainable practices in the coloring industry.

-

Thermal Stability Analysis of Bromo Indigo Pigments

NewsJun.06,2025

-

Sulphur Black Dye Oxidation Process Optimization

NewsJun.06,2025

-

Lightfastness Testing of Bromo Indigo Dyed Denim

NewsJun.06,2025

-

Granule Size Distribution and Jeans Color Uniformity

NewsJun.06,2025

-

Gradient Dyeing Methods with Indigo Blue Granules

NewsJun.06,2025

-

Dyeing Temperature Effects on Sulphur Black Color Fastness

NewsJun.06,2025

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

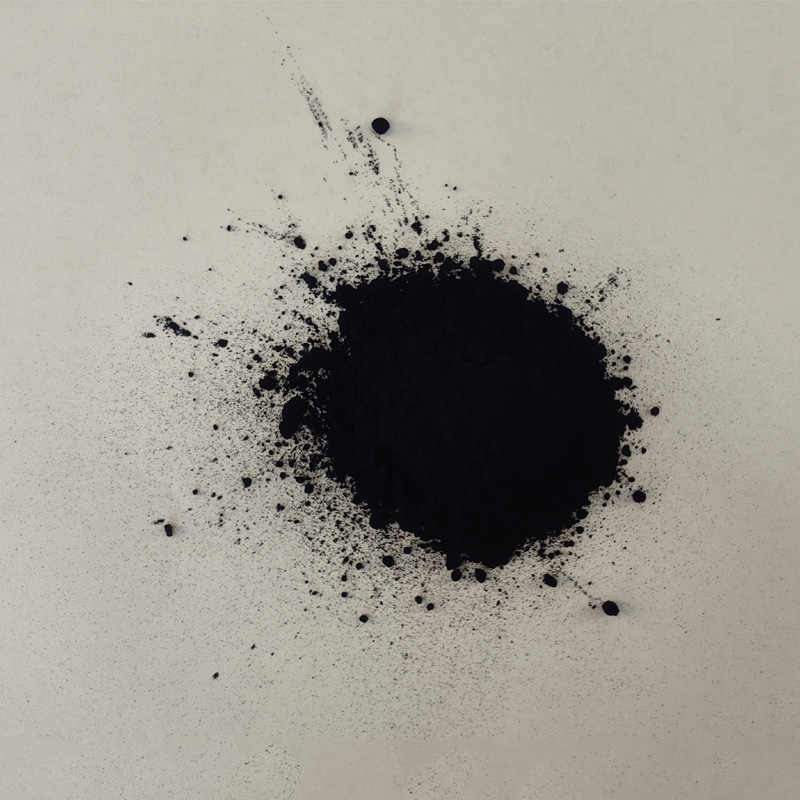

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.