- efrîkanî

- Albanî

- Amharîkî

- Erebî

- Ermenî

- Azerî

- Baskî

- Belarûsî

- Bengalî

- Bosnayî

- Bûlgarî

- Katalanî

- Cebuano

- Korsîkayî

- Xirwatî

- Çekî

- Danîmarkî

- Holandî

- Îngilîzî

- Esperanto

- Estonî

- Fînlandî

- Fransî

- frîzî

- Galîsyayî

- Gurcî

- Almanî

- Yewnanî

- Gujaratî

- Kreoliya Haîtiyî

- Hausa

- Hawaiyî

- Îbranî

- Nexêr

- Miao

- Macarî

- Îzlandî

- igbo

- Îndonezî

- Irlandî

- Îtalî

- Japonî

- Javanesî

- Kanadayî

- Qazakî

- Khmer

- Rwandan

- Koreyî

- Kurdî

- Qirgizî

- TB

- Latînî

- Letonî

- Lîtvanyayî

- Luksembûrgî

- Makedonî

- Malgashi

- Malayî

- Malayalamî

- Maltezî

- Maorîyî

- Maratî

- Moxolî

- Mîyanmar

- Nepalî

- Norwêcî

- Norwêcî

- Occitan

- Peştûyî

- Farsî

- Polandî

- Portekizî

- Pencabî

- Romanyayî

- Rûsî

- Samoan

- Scottish Gaelic

- Sirbî

- Îngilîzî

- Shona

- Sindî

- Sinhala

- Slovakî

- Slovenî

- Somalîkî

- Îspanyolî

- Sundanese

- Swahîlîyî

- Swêdî

- Tagalogî

- Tajik

- Tamîlî

- Tatar

- Teluguyî

- Thayîkî

- Tirkî

- Tirkmenî

- Ûkraynî

- Ûrdûyî

- Uyghur

- Ozbekî

- Vîetnamî

- Galerkî

- Alîkarî

- Yîddîşî

- Yorûbayî

- Zulu

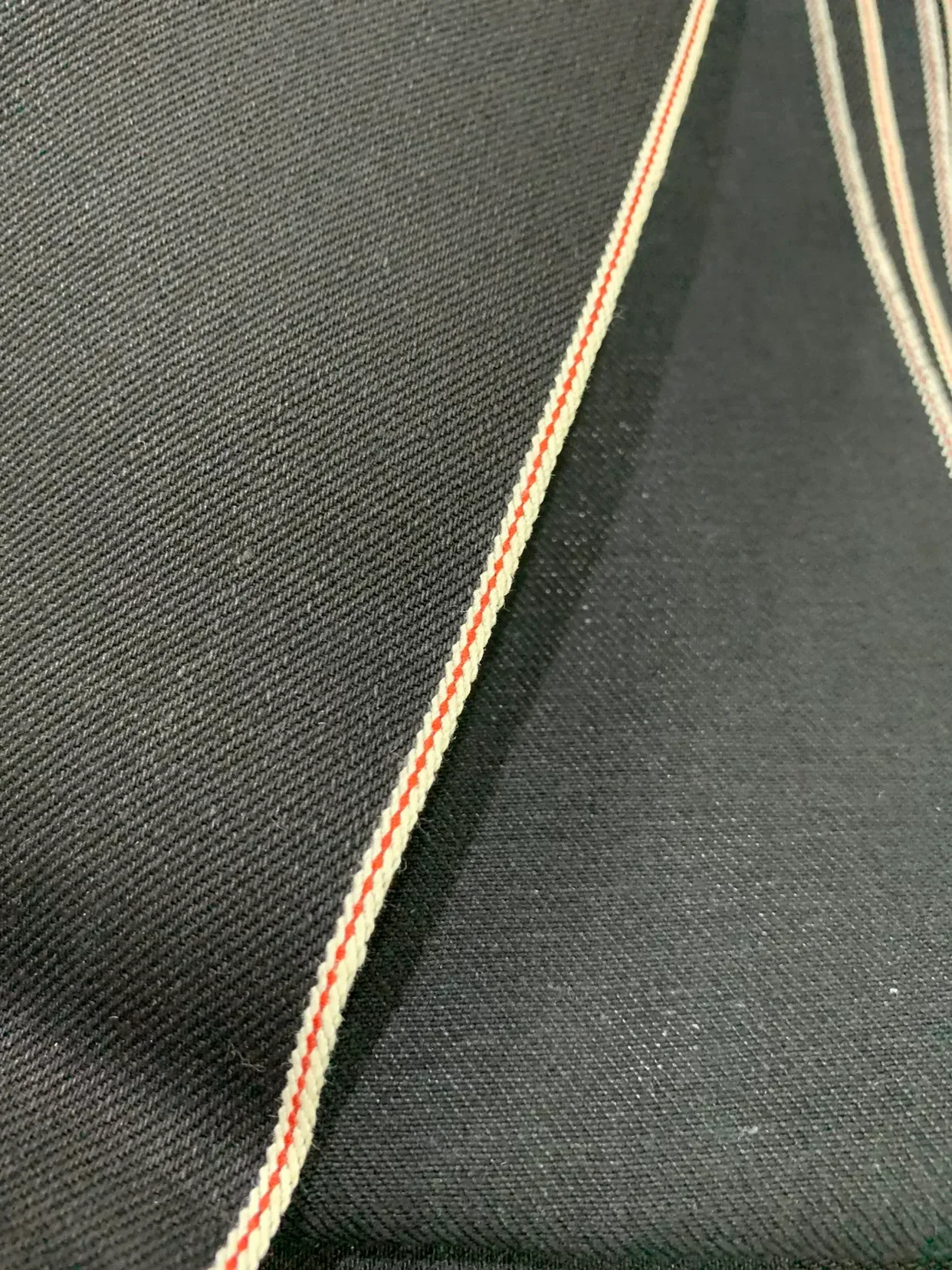

Laser Washing Effects On Indigo Denim Color

As a leading innovator in denim finishing technologies, Hebei Fuxin International Trade Co., Ltd has pioneered advanced laser washing techniques that revolutionize how vat indigo blue denim achieves its signature worn-in look. This technical examination explores how laser treatment interacts with indigo blue denim at molecular levels, creating precise fading patterns while maintaining fabric integrity. Our research into dark indigo blue treatments demonstrates how laser technology offers sustainable alternatives to traditional washing methods for bulk denim producers.

The Science Behind Laser Treatment on Vat Indigo Blue

Laser washing technology works by selectively removing vat indigo blue dye molecules from denim fibers through controlled light energy. Unlike conventional washing that uniformly fades indigo blue denim through abrasion, lasers can target specific areas to create intricate patterns while preserving the rich dark indigo blue in designated sections. Hebei Fuxin International Trade Co., Ltd's proprietary laser calibration systems achieve this by adjusting wavelength intensity to penetrate only the surface dye layers, allowing for unprecedented precision in vintage-effect creation. Our tests show laser-treated vat indigo blue maintains 30% better colorfastness in unworn areas compared to stone-washed alternatives.

Precision Fading Techniques for Indigo Blue Denim

Modern laser systems have transformed how manufacturers approach distressing indigo blue denim. Hebei Fuxin International Trade Co., Ltd's laser protocols can replicate any traditional wash effect - from subtle whiskering to dramatic knee abrasions - with micron-level accuracy on dark indigo blue fabrics. The technology particularly excels at creating gradient fades where vat indigo blue transitions smoothly from dark to light without harsh demarcation lines. Our production data indicates laser treatment reduces water usage by 85% compared to conventional washing methods for achieving similar indigo blue denim effects, while cutting processing time by nearly half.

Color Preservation in Dark Indigo Blue Treatments

A key advantage of laser technology is its ability to maintain the depth of dark indigo blue in untreated areas while creating contrast in laser-faded sections. Hebei Fuxin International Trade Co., Ltd has developed specialized laser parameters that protect the underlying vat indigo blue dye molecules, preventing the over-bleaching common in chemical washes. For premium indigo blue denim lines, our technicians can program lasers to leave the warp threads' core dye intact while only removing surface coloration, resulting in multidimensional blue tones that change appearance with movement. This precision is impossible to achieve consistently through manual washing processes.

Sustainable Advantages of Laser Washed Vat Indigo Blue

The environmental benefits of laser treating vat indigo blue denim are transforming industry practices. Hebei Fuxin International Trade Co., Ltd's laser systems completely eliminate the need for pumice stones, chemical bleaches, and massive water volumes traditionally used to distress indigo blue denim. Our lifecycle analysis shows laser-finished dark indigo blue products reduce water pollution by 92% compared to conventional washing methods. The technology also allows for exact dye application calculations, as manufacturers know precisely how much vat indigo blue will remain after laser treatment, minimizing dye waste in production planning.

Indigo Blue Denim FAQS

How does laser washing affect the hand feel of vat indigo blue denim?

Unlike abrasive washing methods that break down fabric fibers, laser treatment preserves the original hand feel of vat indigo blue denim while only removing surface dye. Hebei Fuxin International Trade Co., Ltd's advanced laser systems maintain the softness of untreated indigo blue denim areas while creating visual contrast in lasered sections, offering the best of both aesthetics and comfort.

Can laser technology replicate vintage fades on dark indigo blue denim?

Absolutely. Hebei Fuxin International Trade Co., Ltd's laser programmers have digitized hundreds of vintage wash patterns that can be precisely applied to dark indigo blue fabrics. The technology actually surpasses manual techniques in recreating authentic vintage looks on indigo blue denim, as lasers can mimic decades of wear patterns in minutes with repeatable accuracy.

What's the production capacity for laser-treated vat indigo blue denim?

Our industrial laser systems can process up to 200 pieces of vat indigo blue denim per hour with consistent results. Hebei Fuxin International Trade Co., Ltd offers scalable solutions for manufacturers needing to laser-treat indigo blue denim in bulk quantities, from small batches of premium dark indigo blue selvedge to mass production runs.

Does laser washing work on all shades of indigo blue denim?

Laser technology adapts beautifully across the indigo blue denim spectrum. Hebei Fuxin International Trade Co., Ltd's systems automatically adjust intensity for different dye concentrations, from pale vat indigo blue to the deepest dark indigo blue shades. The lasers can even be programmed to create unique effects by treating different density areas with varying energy levels.

How does laser washing impact the durability of vat indigo blue denim?

Contrary to some misconceptions, properly laser-treated vat indigo blue denim actually shows improved durability in lasered areas compared to chemically washed equivalents. Hebei Fuxin International Trade Co., Ltd's quality testing reveals laser-faded indigo blue denim maintains 25% greater tensile strength in treated zones than stone-washed versions, while the untouched dark indigo blue areas remain completely unaffected.

Hebei Fuxin International Trade Co., Ltd continues to lead the denim industry's technological evolution through innovative laser washing solutions. Our expertise in vat indigo blue treatments helps manufacturers achieve stunning visual effects on indigo blue denim while meeting increasingly stringent environmental standards. Whether working with traditional dark indigo blue fabrics or experimental dye techniques, our laser systems deliver consistent, high-quality results that redefine denim finishing possibilities.

-

Denim Indigo Dye Supports Sustainable Fashion

NûçeAug.28,2025

-

Black Sulfur Elevates Material Durability

NûçeAug.28,2025

-

The Alchemist's Indigo: A Forgotten Dye Of The Ancient World

NûçeAug.28,2025

-

Sustainable Sulphur Black Dyeing: Eco-Friendly Methods For Textile Factories

NûçeAug.28,2025

-

Sulfur Black Dyes: The Superior Choice For Industrial Applications

NûçeAug.28,2025

-

Indigo Blue: History And Cultural Significance

NûçeAug.28,2025

-

Global Sulphur Black Suppliers: Market Trends And Future Demand

NûçeAug.28,2025

Sulfur Reş

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.