Leading Manufacturers of Indigo Color Dye for Textile Applications

The Indigo Color Dye Manufacturer A Journey Through History and Production

Indigo dye, a deep blue color that has captured the imagination of artists, designers, and consumers for centuries, is derived from the indigo plant or synthetically produced. As the global demand for this rich hue continues to rise, the role of indigo color dye manufacturers has become critical in ensuring a sustainable and authentic supply of this valuable dye.

Historical Significance of Indigo

The history of indigo dye is as vibrant as its color. Dating back over 6,000 years, indigo was one of the earliest dyes used by various civilizations, including the Egyptians, Greeks, and Indians. The dye was prized not only for its beautiful shade but also for its colorfastness. Ancient methods often involved fermentation processes where indigo leaves were soaked and fermented to extract the dye.

The cultivation and production of indigo became a significant economic activity in many regions, particularly in India, where it was known as Neel and formed the backbone of the textile industry. The indigo trade flourished during the colonial period, leading to the establishment of plantations in various countries, including parts of Africa and the Americas.

Modern Indigo Dye Production

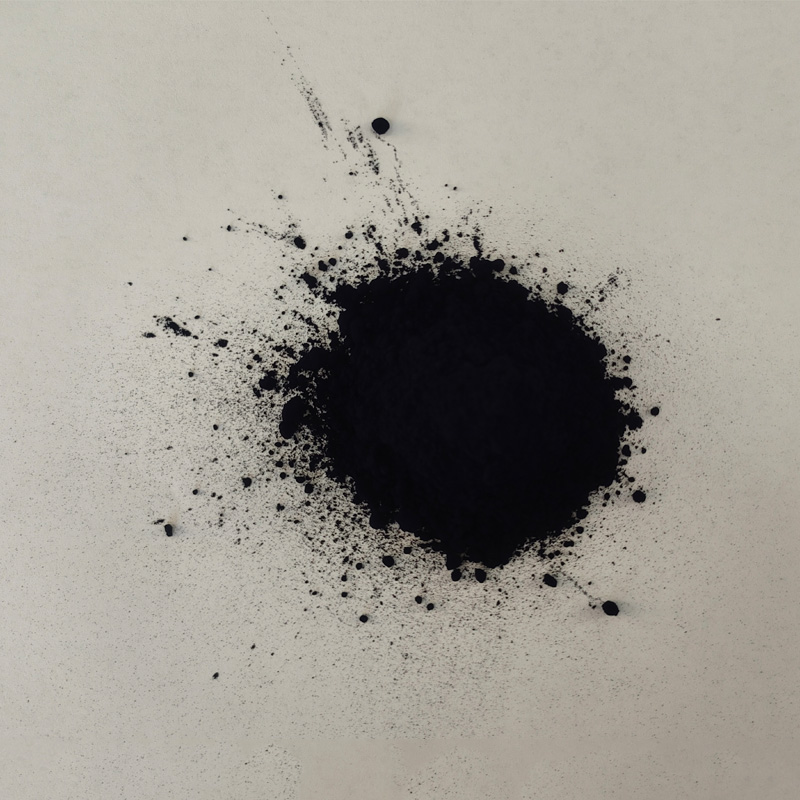

Today, the process of manufacturing indigo dye has evolved but retains much of its traditional essence. Modern indigo dye manufacturers utilize both natural and synthetic methods to produce the dye. The natural method continues to involve the harvesting of indigo plants, primarily Indigofera tinctoria. These plants undergo a fermentation process that helps in extracting the dye, which is then processed into powdered form for textile applications.

On the synthetic side, chemists have developed artificial indigo, which is produced from petrochemicals. This production method offers several advantages, including a more consistent color product, lower cost, and a reduced risk of crop failure. However, the environmental implications of synthetic dye production cannot be overlooked, prompting manufacturers to explore more sustainable practices.

Sustainability in Indigo Dye Manufacturing

indigo color dye manufacturer

As awareness of environmental issues has grown, so has the demand for sustainable and eco-friendly practices in dye production. Indigo manufacturers are increasingly turning to organic farming methods, ensuring that their crops are grown without harmful pesticides and fertilizers. This not only benefits the environment but also supports the health and livelihoods of farming communities.

Furthermore, many manufacturers are investing in innovative production processes that reduce water usage and minimize waste. For instance, some companies are adopting closed-loop systems where wastewater is treated and reused during the dyeing process, greatly reducing the environmental footprint.

The Role of Technology

Advanced technology is revolutionizing the indigo dye manufacturing sector. Innovations such as digital dyeing technologies allow for precise color application, reducing the amount of dye needed while maintaining high-quality output. These technical advancements help manufacturers to meet the increasing demand for indigo across various industries, including fashion, interior design, and art.

Moreover, computer-assisted design (CAD) tools enable designers to visualize and experiment with indigo shades before production, ensuring that the final product aligns with aesthetic requirements. This integration of technology not only streamlines the manufacturing process but also nurtures creativity and innovation in using indigo in new contexts.

Conclusion

The journey of indigo color dye manufacturers is a testament to the blend of tradition and modernity. From its ancient roots to contemporary production methods, indigo continues to play a pivotal role in the textile industry and beyond. As consumers increasingly seek sustainable and eco-friendly products, the future of indigo dye manufacturing looks promising, emphasizing the importance of environmentally-conscious practices.

Embracing both the historical significance and modern advancements in the industry, indigo dye manufacturers are paving the way for a sustainable future while celebrating the enduring allure of this captivating color. Whether in the form of artisanal hand-dyed fabrics or synthetic applications, indigo remains a vibrant symbol of cultural heritage and innovation, ensuring its place in the hearts of many for generations to come.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.