OEM Indigo Powder Dyeing for Custom Fabric Solutions and Sustainable Fashion

The Art of OEM Dyeing with Indigo Powder

Indigo dyeing is one of the oldest and most fascinating textile dyeing techniques in the world, often celebrated for the vibrant and rich hues it produces. When combined with Original Equipment Manufacturer (OEM) practices, the use of indigo powder offers innovative possibilities in textile manufacturing, providing brands with unique opportunities to create customized designs while maintaining sustainable practices.

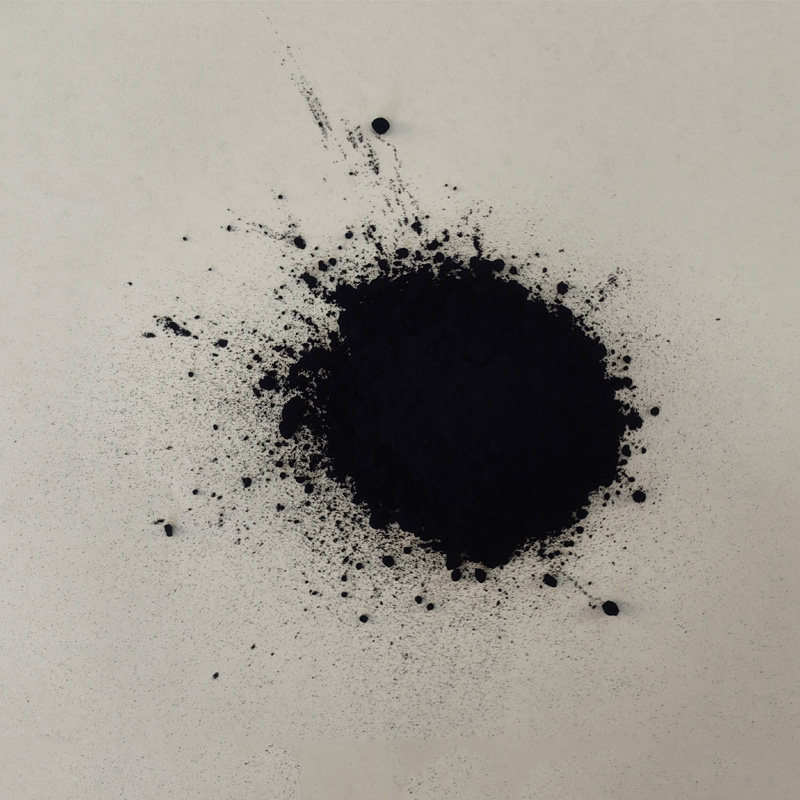

Understanding Indigo Powder

Indigo dye is derived from the leaves of the Indigofera plant, which has been used for centuries to produce a striking blue color. The indigo powder itself is a natural dye made by fermenting and drying the leaves. Unlike synthetic dyes, indigo is biodegradable and non-toxic, making it a popular choice among environmentally conscious brands. The process of dyeing with indigo is unique; it involves the reduction of indigo into a soluble form in an alkaline dye bath. Once the fabric is submerged in this solution and removed, it is exposed to air, allowing the indigo to oxidize and develop its characteristic blue hue.

The OEM Advantage

The term OEM refers to companies that produce goods that are marketed and sold by other brands. In the textile industry, OEM dyeing services enable brands to outsource their dyeing processes while customizing colors, patterns, and materials according to their specifications. This approach offers several advantages

1. Customization Brands can create exclusive products that resonate with their target audience. By utilizing indigo powder, companies can develop unique shades and patterns that enhance their identity in a competitive market.

2. Quality Control Partnering with experienced OEM manufacturers ensures that the dyeing process adheres to high-quality standards. This is crucial, especially with natural dyes like indigo, which require precise craftsmanship to achieve the desired results.

oem dyeing with indigo powder

3. Sustainability As consumers increasingly demand eco-friendly products, using indigo powder aligns with sustainable practices. OEM partners can implement processes that focus on waste reduction and water conservation, enhancing the brand's commitment to environmental responsibility.

4. Cost Efficiency Outsourcing dyeing processes can lead to significant cost savings for brands. OEM partners often have established supply chains and the expertise necessary to dye fabrics efficiently, allowing brands to focus on their core business activities.

Techniques in Indigo Dyeing

The process of dyeing with indigo powder can vary, but some techniques have gained prominence. One popular method is shibori, a Japanese technique that involves folding, twisting, or bunching the fabric before dyeing, creating intricate patterns that reflect the beauty of indigo’s depth. Another common technique is ikat, where the threads are dyed before weaving, resulting in beautiful blurred designs that are distinctive and eye-catching.

Additionally, the dip dye method allows multiple layers of indigo dyeing, leading to darker and more intense shades with each dip. OEM partnerships can enhance these techniques, allowing for innovative applications in creating fashion-forward garments and home textiles.

Conclusion

In the realm of textile dyeing, OEM practices combined with indigo powder offer a unique pathway for creativity, sustainability, and economic efficiency. By leveraging the advantages of indigo dyeing, brands can create memorable products that not only stand out in the marketplace but also resonate with consumers' growing interest in ethical fashion. As the industry evolves, the timeless art of indigo dyeing continues to inspire and connect artisans, brands, and consumers, fostering a deeper appreciation for craftsmanship and sustainability in textiles. Thus, OEM dyeing with indigo powder is not just a technique; it's a movement toward a more innovative and responsible future in fashion.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.