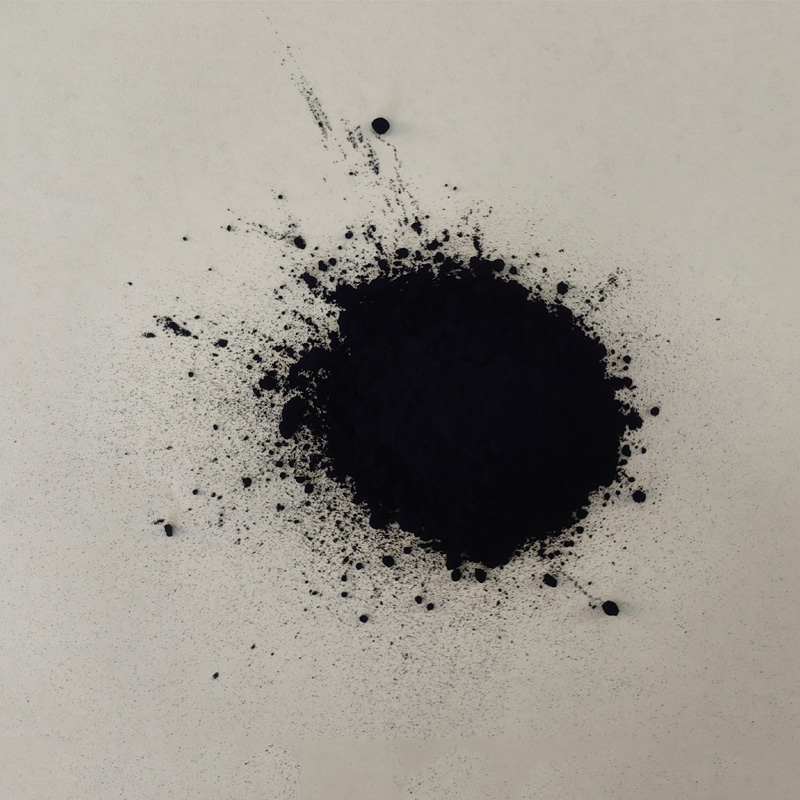

pure organic indigo powder factory

The Art and Science of Pure Organic Indigo Powder Production

Indigo, often referred to as the color of the sky and the sea, has fascinated humanity for centuries. Its rich and vibrant hue has been utilized in textiles, art, and cosmetics. At the heart of this captivating coloration is pure organic indigo powder, a product deeply rooted in tradition yet enhanced by modern sustainable practices. This article explores the world of pure organic indigo powder production, focusing on the ins and outs of its manufacturing process, benefits, and its position in today's eco-conscious marketplace.

Understanding Indigo and Its Historical Significance

Indigo dyeing has a remarkable history that stretches back thousands of years. Ancient Egyptians, Indian artisans, and indigenous communities in the Americas have all harnessed the unique properties of indigo, creating garments and artworks that withstand the test of time. Indigo dye is derived from the leaves of the Indigofera plant, with the oldest known references dating back to the 6th century B.C.

In traditional practices, indigo was valued not only for its color but also for its cultural significance. Regions like West Africa and South Asia developed distinct dyeing techniques that transformed textiles into durable, vibrant pieces synonymous with local heritage.

The Shift to Organic Production

With the rise of sustainable fashion, there has been a concerted effort to shift towards organic production techniques in recent years. The demand for pure organic indigo powder reflects a growing awareness of environmental issues associated with synthetic dyes and chemical-heavy practices. Organic indigo farming emphasizes the use of natural methods that exclude harmful pesticides and fertilizers.

Pure organic indigo powder is obtained through a meticulous process that prioritizes ecological balance. Farmers cultivate Indigofera plants using regenerative agricultural practices, such as crop rotation and natural pest management. This approach not only protects biodiversity but also enhances soil health, ensuring the sustainability of indigo farming for future generations.

The Production Process of Pure Organic Indigo Powder

The production of pure organic indigo powder involves several key stages

pure organic indigo powder factory

1. Cultivation The journey begins with the cultivation of indigo plants. Ideally, a warm, humid climate is required for optimal growth, commonly found in countries like India, Peru, and Madagascar. Farmers select high-quality seeds and nurture the plants throughout their growth cycle.

2. Harvesting Once the plants reach maturity, their leaves are harvested. This usually occurs when the leaves are at their peak, as this enhances the pigment’s quality. Harvesting is often done by hand to ensure minimal damage to the plants.

3. Fermentation The harvested leaves are then subjected to a fermentation process to convert the indican present in the leaves into water-soluble indigo. This process usually takes several days and can involve adding water and natural substances to encourage fermentation.

4. Drying and Pulverizing After fermentation, the indigo is extracted, dried, and transformed into a fine powder. This step is crucial as it ensures that the indigo is pure and ready for various applications.

5. Quality Control A vital component of the production process, quality control checks are conducted to ensure the indigo powder meets the highest standards. This step includes testing the pigment concentration and checking for contaminants.

Applications and Benefits

Pure organic indigo powder is celebrated for its versatility. It can be used in various applications, including textile dyeing, cosmetics, and art supplies. Its natural composition ensures that it is free from harmful chemicals, making it a safe choice for consumers.

Additionally, indigo dyeing is known for its ecological advantages. Unlike synthetic dyes, indigo adheres to textiles in a way that requires fewer water resources and reduces runoff of harmful chemicals into the environment. This makes pure organic indigo powder a beacon of hope for the sustainable fashion movement.

Conclusion

The pure organic indigo powder factory exemplifies a harmonious blend of tradition and innovation. By embracing sustainable practices, it offers a product that not only pays homage to the cultural heritage of indigo dyeing but also aligns itself with modern environmental values. As consumers continue to seek eco-friendly alternatives, pure organic indigo powder stands out as a powerful testament to what conscious craftsmanship can achieve. Whether adorning fabric or enhancing artworks, this vibrant dye will undoubtedly continue to color our lives while respecting the earth.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.