Affordable Sulphur Dyeing Techniques for Vibrant and Cost-Effective Color Solutions

Exploring Cheap Sulphur Dyeing An Economic Approach to Textiles

The textile industry has long been under scrutiny for its environmental impacts and the rising costs associated with traditional dyeing methods. One solution that has gained traction in recent years is cheap sulphur dyeing, a process that not only offers economic benefits but also presents a more sustainable alternative to conventional dyeing techniques. This article will delve into the advantages, processes, and considerations of sulphur dyeing, positioning it as a viable option for both manufacturers and consumers.

Understanding Sulphur Dyes

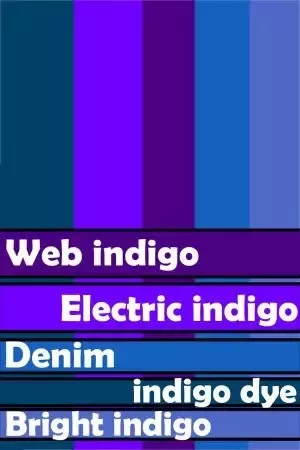

Sulphur dyes are a category of colorants that are primarily used for dyeing cellulose fibers, such as cotton. They are derived from sulphur compounds and are prized for their excellent lightfastness and overall color stability. These dyes are affordable, making them attractive to manufacturers who aim to lower production costs while maintaining quality. Moreover, sulphur dyes can produce a wide range of colors, from deep, rich hues to lighter shades, making them versatile for various applications in the textile industry.

Cost-Effectiveness of Sulphur Dyeing

One of the most compelling arguments for adopting sulphur dyeing is its cost-effectiveness. Traditional dyeing methods often require expensive pigments and complicated procedures that can drive up the overall cost of fabric production. In contrast, sulphur dyes are typically cheaper to produce and apply. The dyeing process consists of a simple fermentation and a reductive process, which not only reduces the material cost but also optimizes the utilization of resources.

Additionally, sulphur dyeing requires less water compared to other dyeing methods, which can significantly lower operational costs in regions where water scarcity is a concern. This reduction in water use can also translate into lower energy costs associated with heating and cooling, further increasing profitability for textile manufacturers.

Eco-Friendly Aspects of Sulphur Dyeing

cheap sulphur dyeing

In recent years, environmental sustainability has become a focal point within the textile industry. The use of sulphur dyes aligns with eco-friendly practices due to their reduced water usage and the lower environmental impact associated with their application. Unlike many synthetic dyes that can release toxic substances into water systems, sulphur dyes tend to be less harmful when managed appropriately.

Moreover, the by-products generated during the dyeing process can often be treated more easily than those from traditional dyeing methods, leading to a decrease in environmental pollution. The long-lasting quality of sulphur dyes also means that dyed fabrics maintain their color over time, reducing the need for frequent re-dyeing and further minimizing waste.

Challenges and Considerations

Despite the advantages, there are challenges associated with sulphur dyeing that manufacturers must consider. The dyeing process requires precise control over pH and temperature, as variations can lead to inconsistent coloring or color loss. Furthermore, while sulphur dyes are generally less toxic, inappropriate handling can still pose risks both to workers and the environment, making proper training and safety measures essential.

Additionally, while sulphur dyes are known for their affordability, the market dynamics can fluctuate due to demand and availability of raw materials. Manufacturers must stay informed about these trends to ensure continued cost-effectiveness.

Conclusion

Cheap sulphur dyeing offers a promising avenue towards making textile production more economical and environmentally friendly. With the potential to significantly reduce costs while promoting sustainable practices, sulphur dyes are becoming an increasingly popular choice in the industry. As manufacturers continue to innovate and improve upon dyeing techniques, the integration of sulphur dyes may well play a pivotal role in the future of the textile sector. By balancing cost, quality, and environmental stewardship, cheap sulphur dyeing could drive positive change within an industry often characterized by its challenges.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.