sulphur black msds factories

An Overview of Sulphur Black and Its Safety Data Sheets (MSDS) in Manufacturing

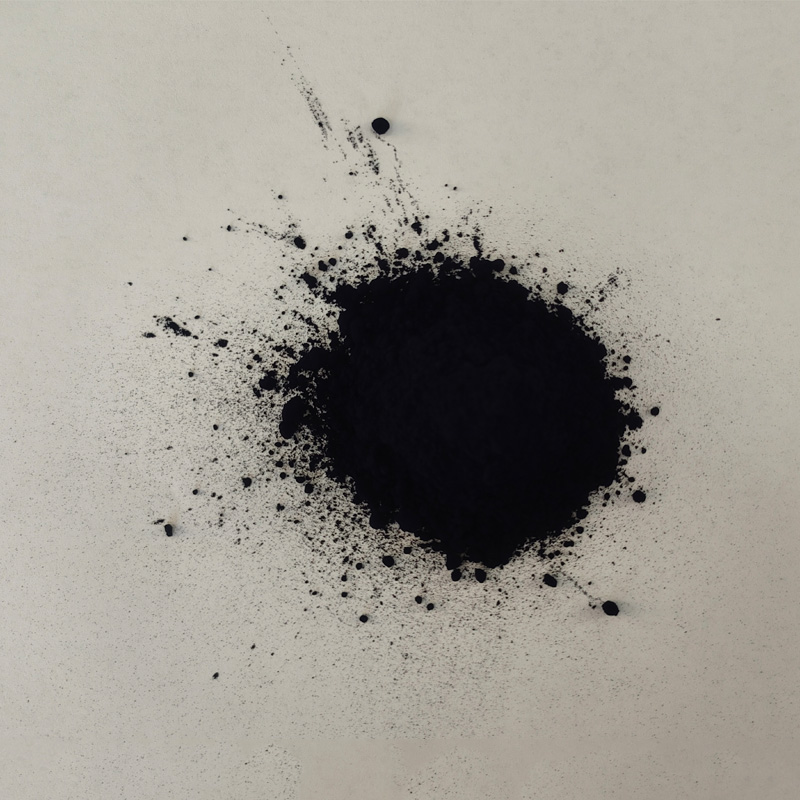

Sulphur black is a widely used dye known for its deep black color and excellent lightfastness, making it a staple in various industries, particularly in textile manufacturing. As markets across the globe strive for higher quality products, the importance of understanding the materials used in production processes has become paramount. This article delves into the critical information contained in Material Safety Data Sheets (MSDS) associated with sulphur black and its implications for factories utilizing this dye.

What is Sulphur Black?

Sulphur black refers to a group of black dyes derived from the reaction of sulphur with organic compounds. These dyes are typically insoluble in water but can be made soluble under alkaline conditions, which makes them suitable for dyeing a variety of fabrics, especially cotton and other cellulose fibers. The primary benefits of sulphur black include its cost-effectiveness, brilliance, and durability. However, its application must be accompanied by a thorough understanding of the associated hazards and safety protocols necessary to protect workers and the environment.

Importance of Material Safety Data Sheets (MSDS)

Material Safety Data Sheets (MSDS), now more frequently referred to as Safety Data Sheets (SDS), are vital documents that provide comprehensive information about a chemical substance, including its properties, hazards, handling instructions, and emergency measures. For sulphur black, the MSDS outlines the physical and chemical properties, potential health risks, safe handling procedures, and protocols for exposure or spillage.

Understanding and utilizing the MSDS for sulphur black is crucial for manufacturers, as it serves as a guideline to ensure workplace safety, regulatory compliance, and environmental protection. By adhering to the information set forth in the MSDS, factories can avoid potential health complications for workers and mitigate the risk of environmental contamination.

Key Information in the MSDS for Sulphur Black

1. Chemical Identification The MSDS will begin with the chemical identity of sulphur black, including synonyms (e.g., Sulphur Black 1, Sulphur Black 2), molecular structure, and common applications. This information is critical for proper identification and potential trade names that may be used in the market.

sulphur black msds factories

2. Hazard Identification This section delineates the hazards associated with sulphur black, such as skin and eye irritation, respiratory issues when inhaled, and environmental risks. Clear identification of the nature and severity of these hazards helps in assessing workplace safety.

3. Composition/Information on Ingredients Factories need to know the proportion of different substances in sulphur black. This section of the MSDS clarifies the main components and any hazardous substances that may be present, allowing facilities to adhere to legal limits.

4. First Aid Measures The MSDS outlines necessary first aid measures in case of exposure. This includes specific actions depending on the route of exposure inhalation, ingestion, or skin contact. Knowledge of these procedures can make a critical difference in emergency situations.

5. Fire Fighting Measures The risk of fire and the appropriate extinguishing methods are discussed in this section. Understanding the flammability of sulphur black and the recommended fire-fighting media ensures factories are equipped to handle emergencies safely.

6. Handling and Storage Guidelines for the safe handling and storage of sulphur black highlight best practices to prevent accidents. This includes recommendations for personal protective equipment (PPE), good hygiene practices, and information on keeping the product in suitable conditions to prevent degradation or hazardous reactions.

7. Environmental Impact As factories increasingly face scrutiny on environmental practices, the MSDS provides guidance on waste management and disposal of sulphur black. Responsible handling and disposal are crucial in minimizing ecological harm.

Conclusion

Premiering as an essential component in textile dyeing, sulphur black must be treated with due caution and responsibility. The MSDS serves not only as a crucial tool for understanding its properties and hazards, but also as a framework for promoting workplace safety and environmental sustainability. By diligently adhering to the guidelines provided in these documents, factories can ensure the health of their employees and the surrounding community while working efficiently with sulphur black. Education and training regarding MSDS are vital for manufacturing operations that utilize this dye, fostering a safer and more compliant industry.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.