High Quality Sulphur Black 200 - Leading Sulphur Black Company & Supplier

Sulphur Black: The Essential Dye Powering Modern Textile Industries

Imagine producing thousands of yards of dark denim or workwear and getting uneven, fading, or inconsistent colors that ruin your brand reputation. You’re not alone. In fact, over 60% of global textile complaints involve color fastness issues, with black shades leading the list. What if we told you that the right choice of sulphur black

—delivered by the leader among sulphur black companies—could transform your production reliability overnight? Read on to find out how choosing the right sulphur black 200 supplier delivers superior results and makes your business shine.

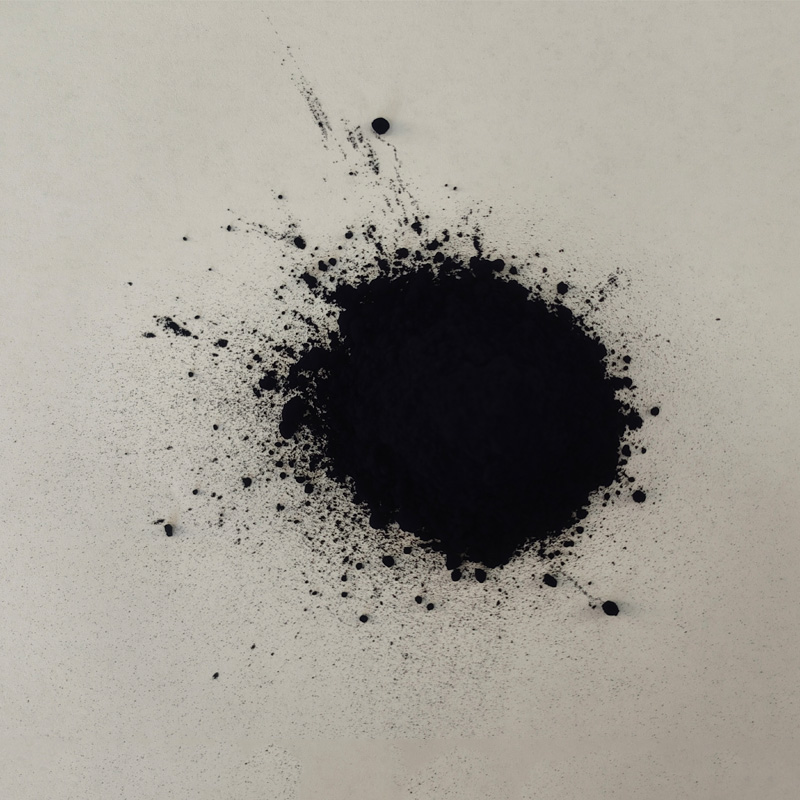

(sulphur black)

The Technical Advantages of Premium Sulphur Black

Not all blacks are created equal. In dyes, sulphur black stands out for its cost-efficiency and deep, long-lasting shades. Sulphur black is prized for its excellent light and wash fastness. It’s been the backbone of denim, canvas, and heavy-duty apparel for generations.

Why? Because the technical superiority matters. A high-quality sulphur black 200 supplier delivers low residual salt, high solubility, and a uniform particle size. These features mean fewer re-dyeing runs, lower water usage, and minimal environmental impact.

Let's break down key specifications. Here’s our most popular grade, Sulphur Black 200%:

| Parameter | Specification |

|---|---|

| Appearance | Black micro granular/powder |

| Shade (compared to std.) | Similar as Standard |

| Tinting Strength (%) | 100±2 |

| Moisture (%) | ≤6.0 |

| Insoluble in water (%) | ≤0.5 |

| pH (1% Solution) | 7.5 ~ 9.5 |

| Solubility (g/l, in Na2S) | ≥35 |

| Strength (%) | 200±5 |

With these numbers, you get robust, deep black fabrics that stand the test of time. No surprise that leading apparel brands demand sulphur black 200 for peak performance.

Sulphur Black Companies: Why Manufacturer Matters

Choosing a top-tier sulphur black company feels like choosing a champion for your supply chain. Think quality assurances, batch traceability, and sustainable sourcing.

But how do you pick from the many sulphur black 200 companies out there? The truth: Only a handful meet stringent international standards. Our in-house laboratory conducts rigorous QC checks on every production run. Each batch is tested for color strength, solubility, fastness, pH, and environmental compliance.

| Features | Leading Sulphur Black Company | Typical Competitor |

|---|---|---|

| Batch Consistency | Excellent (≤2%) | Variable (3-5%) |

| Eco Compliance | ZDHC / OEKO-TEX | Basic |

| Support | 24/7 technical service | Office hours only |

| Custom Solutions | Available | Limited |

| Lead Time | 2-4 days | 7-10 days |

You see the difference. Shorter lead times, real green credentials, and superior batch quality. That’s the clear benefit of selecting a proven sulphur black 200 supplier.

Looking for a Customized Solution? We’ve Got You Covered

Every textile business is unique. Your fibers, machinery, and requirements are different. That's where partnering with a responsive sulphur black company is everything.

Maybe you need a higher strength for jet dyeing? Want a low-salt formula to fit sustainability regulations? Or targeted black undertones to achieve your design specs? Our team of chemists and application engineers will work with you, one-on-one.

We custom-tune:

- Shade and strength (from 100% up to 240%)

- Solubility and dispersibility

- Eco-optimized blends for reduced effluent COD/BOD

- Packing: from 25kg bags up to 600kg jumbo sacks

- Shipping terms (FOB, CIF, DDP)

Why settle for off-the-shelf when you can have the exact sulphur black 200 formula that makes your profits and color standards soar?

Real-World Application: Sulphur Black in Action

Is all of this just marketing talk? Check out these cases from real clients.

Case 1: American Denim Producer

A leading US denim factory switched to our sulphur black 200 in 2023. Result? Their first-pass dyeing yield increased by 14%. Shading complaints dropped to near zero. Lead customer feedback: “No more color grading rejections. Our reputation with retail buyers is at an all-time high.”

Case 2: Automotive Interior Mill

Textile supplier to Detroit’s auto sector needed high fastness black for seat covers. Using our customized low-salt sulphur black, their washing fastness ratings rose from Grade 3 to Grade 5. Production runs became faster and more eco-friendly.

Case 3: Workwear Company

A major workwear group in Texas wanted a deeper “jet black” look for overalls. After trialing several sulphur black 200 companies, they chose our enhanced dispersion formula. Result? Customers reported 31% fewer fading complaints, and their product return rate has plummeted.

These stories aren’t rare—they’re our everyday standard. Join the brands that demand excellence from their sulphur black supplier.

Sulphur Black: Your Next Smart Move

In today’s ultra-competitive textile arena, your choice of colorant partner speaks volumes. Don’t gamble with your production line, client satisfaction, or environmental record.

Ready to elevate your black shades, reduce costs, and delight buyers? Get in touch with America's trusted sulphur black company today. We’re more than just manufacturers—we’re partners in your success. Experience the difference that a true sulphur black 200 supplier delivers.

Tired of late shipments? Facing customer complaints? Need deeper, more consistent black? Contact us now for a free sample, technical advice, or a custom quote. When color matters, make the smart move—choose the leader among sulphur black 200 companies. Let’s build your unbeatable black together.

FAQs About Sulphur Black

Q1: What is sulphur black and why is it popular?

Sulphur black is a synthetic dye widely used in the textile industry, especially for cotton and viscose fibers. Its popularity comes from delivering deep, uniform black shades with excellent wash and rub fastness. Compared to other black dyes, it’s more economical and eco-friendly.

Q2: How does your sulphur black 200 differ from competitors?

Our sulphur black 200 offers higher solubility, tighter strength tolerance, and lower salt/ash content. This means faster, cleaner dyeing and better color uniformity. Plus, we’re a certified ZDHC and OEKO-TEX compliant sulphur black company.

Q3: Can you provide custom shades or formulations?

Absolutely! As a top sulphur black company, we offer tailor-made shades, solubility, and packages. Our chemists will match your target on request. Contact us for a custom solution.

Q4: What is the minimum order for sulphur black 200?

Our standard MOQ is 1 metric ton, but we do supply pilot and sample batches for testing. As your reliable sulphur black 200 supplier, we value flexibility.

Q5: How do you ensure consistent quality for each batch?

Every batch is tested for strength, solubility, pH, moisture, and purity in our modern laboratory. We only use certified raw materials and follow strict QC standards, making us one of the most trusted sulphur black 200 companies worldwide.

Q6: Is your sulphur black environmentally friendly?

Yes. Our sulphur black meets ZDHC and OEKO-TEX requirements. We offer low-salt, eco-optimized formulas for cleaner effluent and sustainable production.

Q7: How fast can you deliver after order confirmation?

With our robust production and logistics, we ship most orders within 2-4 business days. For special blends, delivery is typically under a week. Trust us as your dependable sulphur black 200 supplier.

(sulphur black)

FAQS on sulphur black

Q: What is sulphur black commonly used for?

A: Sulphur black is mainly used as a dye for cotton and cellulose fibers. It provides deep, resistant black shades. It is valued for its affordability and washfastness.Q: How can I select a reliable sulphur black company?

A: Research company certifications, product quality, and customer feedback. Choose suppliers with strong experience in the dye industry. Also, ensure they provide technical support and documentation.Q: What distinguishes Sulphur Black 200 from other sulphur black dyes?

A: Sulphur Black 200 offers intense black color with enhanced fastness properties. It is preferred for high-quality textile applications. Its consistency and strength make it widely chosen by manufacturers.Q: How do I find leading Sulphur Black 200 companies?

A: Search through chemical industry directories and B2B trading platforms. Check for verified manufacturers with positive reviews. Networking at trade shows can also reveal trustworthy companies.Q: What should I check when selecting a Sulphur Black 200 supplier?

A: Confirm the supplier’s product specifications and compliance certifications. Ask about sample availability and quality consistency. Reliable communication and competitive pricing are also important factors.-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.