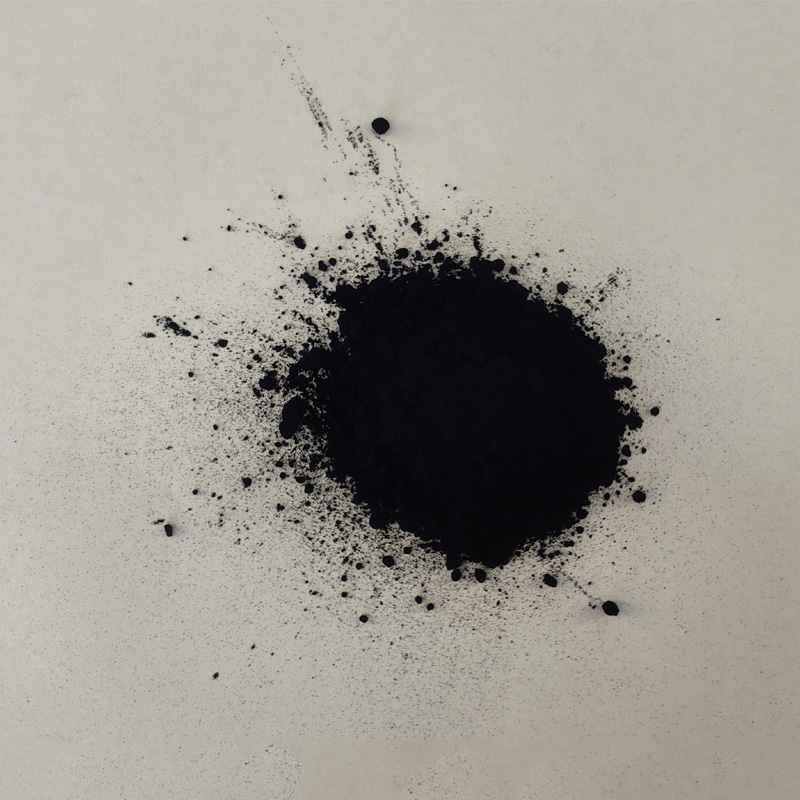

oem indigo natural

Exploring the Origins and Applications of OEM Indigo Natural

In recent years, the market for natural dyes has gained significant momentum as consumers seek sustainable and eco-friendly alternatives to synthetic colorants. Among the various natural dyes, Indigo holds a prominent place due to its rich history and versatile applications. When discussing indigo, the term “OEM Indigo Natural” emerges, referring to Original Equipment Manufacturer products that utilize natural indigo dye. This article will explore the origins of natural indigo, its production process, and its applications in various industries.

The Historical Significance of Indigo

Indigo dye has been celebrated for centuries, dating back to ancient civilizations in Asia, Africa, and the Americas. The name indigo is derived from the Latin word indicum, meaning from India, as it was one of the earliest sources of the dye. Different cultures have relied on indigo for its deep blue hue, which has been used in textiles, pottery, and art.

Historical records indicate that indigo was cultivated and processed in places such as India, West Africa, and Japan. In these regions, indigo became a symbol of wealth and status due to the complexities involved in its production. The dye was extracted from the leaves of the indigo plant (primarily Indigofera tinctoria) and required careful fermentation processes to generate the vibrant colors renowned in various textiles.

The Rise of Natural Dyes in the Modern Age

With the advent of synthetic dyes in the 19th century, indigo experienced a decline in popularity. However, the environmental and health concerns associated with synthetic dyes have prompted a resurgence in natural dyeing practices. As consumers become increasingly aware of the ecological impact of their choices, the shift toward natural alternatives is significant.

OEM Indigo Natural has emerged as a noteworthy player in this trend, emphasizing quality and sustainability in dye production. By collaborating with local farmers and artisans, OEMs ensure that the dye is sourced responsibly, supporting fair trade practices and promoting biodiversity. This approach not only revitalizes traditional methods but also elevates the social and economic conditions of those involved in the indigo supply chain.

The Production Process of OEM Indigo Natural

The process of creating OEM Indigo Natural begins with the careful cultivation of indigo plants. Once harvested, the leaves must undergo fermentation, during which enzymes convert the indican (the glycoside compound found in the leaves) into indigo dye. This fermentation can take several days and requires precise monitoring to achieve optimal results.

oem indigo natural

After fermentation, the indigo is extracted and can be processed into various forms, including powder, liquid, or as a paste. The final product can be tailored to meet the specific requirements of manufacturers looking to dye textiles, garments, or even artisanal crafts.

By utilizing modern technology alongside traditional methods, OEM Indigo Natural can ensure consistency and quality in its dye products. This blending of ancient and contemporary practices results in an indigo dye that not only respects tradition but also meets the rigorous standards of today’s industries.

Applications of OEM Indigo Natural

One of the most prominent applications of OEM Indigo Natural is in the textile industry. From denim to activewear, indigo dye remains a staple due to its vibrant and long-lasting characteristics. Brands that prioritize sustainability are increasingly opting for natural indigo to differentiate their products in a competitive market.

Moreover, the use of OEM Indigo Natural extends beyond textiles. It has found its way into cosmetics, where it is utilized for its coloring properties in makeup formulations. Additionally, artisans use natural indigo in pottery, paint, and ink, showcasing its versatility across various artistic endeavors.

The demand for OEM Indigo Natural is also rising in the food industry, where it is used as a natural coloring agent. Historically, indigo has been used in food products, although caution is necessary regarding culinary applications, as certain compounds can be toxic in large amounts. Nonetheless, ongoing research explores safe, innovative uses of natural indigo in this realm.

Conclusion

As the world shifts toward more sustainable practices, OEM Indigo Natural represents a beacon of hope in the journey towards ecological responsibility in manufacturing. By harnessing the power of traditional textile techniques and modern production methods, OEMs can provide high-quality, sustainable products that resonate with environmentally conscious consumers.

Indigo, with its rich history and diverse applications, continues to be a celebrated natural dye. Its journey from ancient civilizations to contemporary industries reflects not just a commitment to beauty and quality but also a respectful nod to cultural heritage and environmental stewardship. As more brands embrace OEM Indigo Natural, we can look forward to a future where sustainability and creativity go hand in hand.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.