sulphur black msds factories

Understanding Sulphur Black Safety Data and Factory Considerations

Sulphur black, a widely used dye, primarily in the textile industry, provides a deep, rich black color to fabrics. Its unique properties and versatility make it a popular choice among manufacturers. However, like many industrial chemicals, it requires careful handling and an understanding of safety protocols, especially when considering its use in factories. This article aims to shed light on the importance of the Material Safety Data Sheet (MSDS) for sulphur black, focusing on safety, health, and environmental aspects relevant to factories.

What is Sulphur Black?

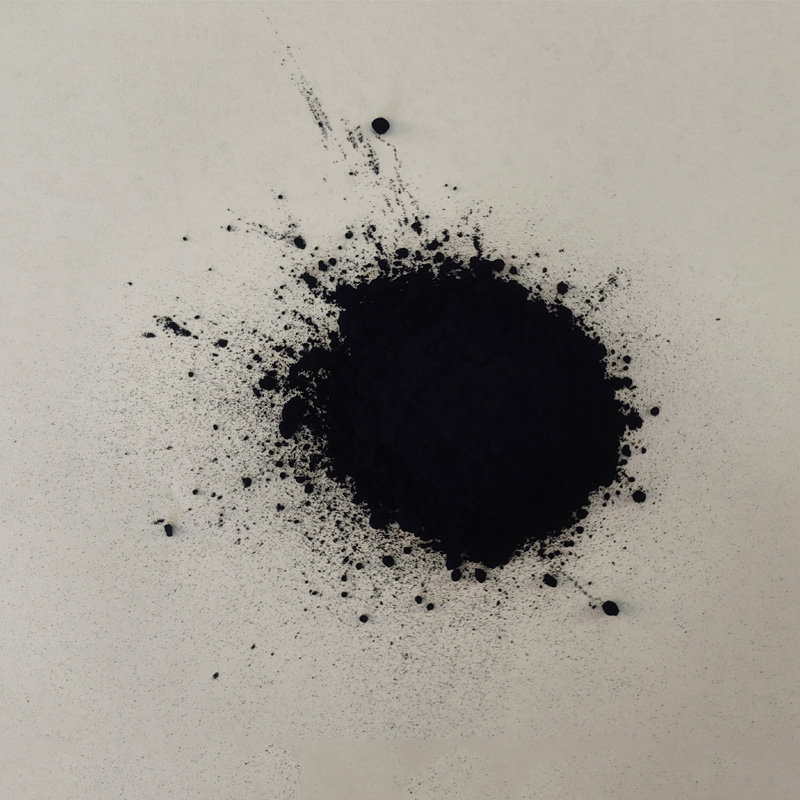

Sulphur black is a type of sulfur-containing dye that is often applied to cotton and other cellulosic fibers. It has excellent lightfastness and wash fastness properties, making it ideal for products subjected to high levels of washing and exposure to sunlight. Typically available in powdered form, sulphur black is soluble in alkaline solutions, allowing it to be used effectively in various dyeing applications.

The Importance of the MSDS

The MSDS is a critical document that provides detailed information about a chemical substance. For sulphur black, the MSDS contains data on its composition, hazards, handling and storage requirements, first aid measures, and environmental considerations. Factories using sulphur black must ensure that employees are familiar with the MSDS to promote safe practices and minimize risks associated with its use.

Health Hazards and Safety Precautions

sulphur black msds factories

Sulphur black can pose several health risks. Inhalation of dust or vapors may lead to respiratory irritation, while skin contact can cause dermatitis. Therefore, it is essential for factory workers to wear appropriate personal protective equipment (PPE), including gloves, masks, and goggles, whenever dealing with this substance. Additionally, proper ventilation in work areas is crucial to reduce the concentration of airborne particulates.

In the event of accidental exposure, the MSDS outlines specific first aid measures. For instance, if sulphur black comes into contact with the skin, the affected area should be washed thoroughly with soap and water. If ingested, medical attention should be sought immediately. Factories should also establish an emergency response plan to address spills and ensure that all employees know how to react in such situations.

Environmental Considerations

The use of sulphur black in industrial settings necessitates a commitment to environmental stewardship. When discharged into water bodies or the environment, the dye can have harmful effects on aquatic life and ecosystems. Factories must adhere to local regulations regarding wastewater management and ensure proper treatment of effluents containing sulphur black before release.

Moreover, factories should explore sustainable practices that limit the use of toxic chemicals and recycled water systems to minimize environmental impact. Employing alternative dyes that offer similar results with less toxicity can also contribute to a more sustainable approach to dyeing processes.

Conclusion

In conclusion, while sulphur black is an essential dye in textile manufacturing, its handling requires a strong emphasis on safety and environmental responsibility. Factories must prioritize their adherence to the MSDS and train their workforce accordingly. By fostering a culture of safety and environmental awareness, companies can enjoy the benefits of using sulphur black while protecting their workers and the planet. Effective communication and proactive measures are vital in ensuring that the use of such chemicals aligns with best practices and industry standards.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.