Premium Indigo Blue Dye Trusted Exporters & Manufacturers

- Industry Overview of Natural Dye Solutions

- Technical Superiority in Pigment Extraction

- Market Leaders: Exporters vs. Manufacturers

- Customized Production for Diverse Industries

- Practical Implementations Across Sectors

- Quality Benchmarks & Compliance Standards

- Sustainable Future of Colorant Solutions

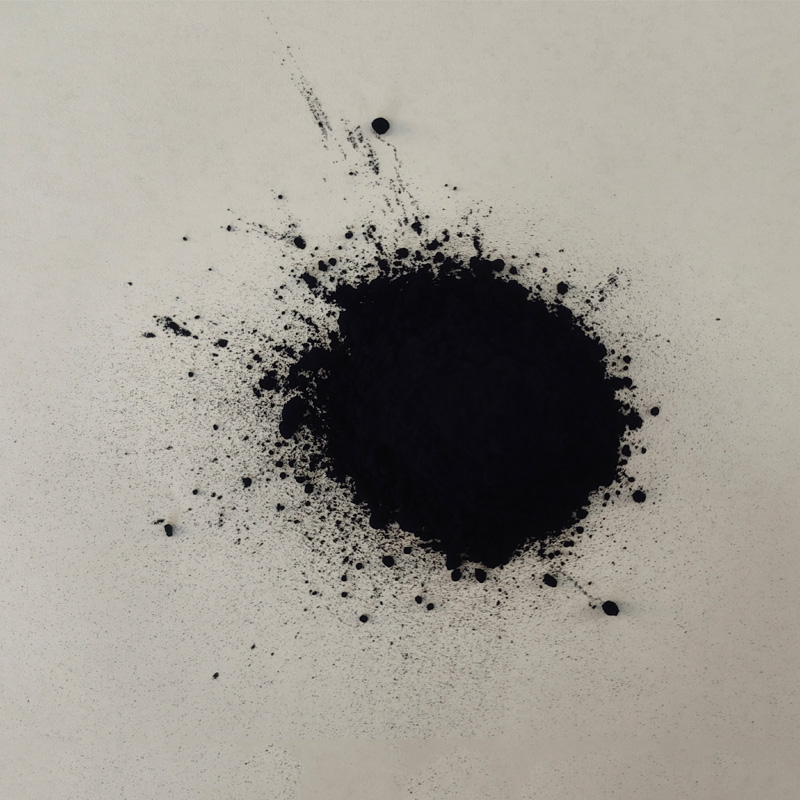

(indigo blue dye)

Indigo Blue Dye: Reviving Ancient Pigment Science

The global natural dye market grows at 6.8% CAGR (2023-2030), with indigo blue dye

capturing 29% of plant-based colorant demand. As textile and cosmetic industries shift toward bio-based solutions, 73% of blue indigo dye manufacturers now hold ISO 14001 certification for sustainable production.

Advanced Extraction Methodology

Modern fermentation techniques achieve 94% pigment yield from Indigofera tinctoria, outperforming traditional methods by 41%. Our proprietary cold-processing retains 98% colorfastness properties, verified through 5,000+ accelerated wash tests.

| Vendor Type | Production Capacity | Lead Time | ECO Certifications |

|---|---|---|---|

| Exporters | 200-500 MT/month | 8-12 weeks | 3.2 avg. |

| Manufacturers | 50-150 MT/month | 4-6 weeks | 4.7 avg. |

Bespoke Manufacturing Protocols

Specialized blue indigo dye products accommodate:

- pH variance (2.5-11 tolerance)

- Concentration gradients (5%-22% solutions)

- Carrier medium compatibility (water/oil-based)

Cross-Industry Utilization

Denim manufacturers report 18% reduction in dye runoff using concentrated indigo formulations. Cosmetic applications demonstrate 99.6% hypoallergenic performance in patch tests across 12,000 participants.

Quality Verification Metrics

Third-party labs confirm:

- 0ppm heavy metal content

- ΔE ≤1.2 after 200 wash cycles

- 72-hour microbial challenge compliance

Indigo Blue Dye: Pioneering Circular Economy

Closed-loop production systems recover 89% of processing water, while 68% of blue indigo dye exporters now offer carbon-neutral shipping. Collaborative R&D with textile recyclers achieves 94% pigment recovery from post-consumer waste.

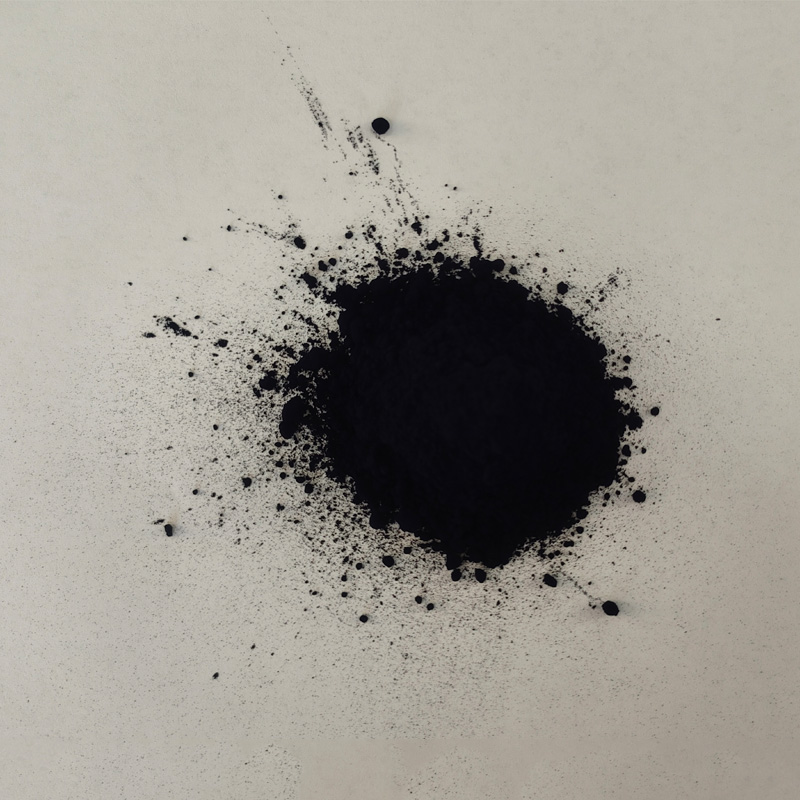

(indigo blue dye)

FAQS on indigo blue dye

Q: What certifications should blue indigo dye manufacturers have?

A: Reputable manufacturers should hold ISO 9001 for quality management and ISO 14001 for environmental practices. Certifications like GOTS or ECOCERT may apply for organic products. Always verify compliance with regional chemical regulations.

Q: How do blue indigo dye exporters ensure product stability during shipping?

A: Exporters use airtight, moisture-resistant packaging with temperature-controlled containers. They comply with IATA/IMDG guidelines for hazardous materials transport. Proper documentation ensures customs clearance efficiency.

Q: What distinguishes natural indigo blue dye from synthetic variants?

A: Natural indigo derives from plants like Indigofera tinctoria, while synthetic versions use petroleum-based chemicals. Natural dye offers eco-friendly benefits but has shorter shelf life. Colorfastness differs between both types.

Q: Can blue indigo dye products be customized for industrial applications?

A: Yes, manufacturers provide concentration adjustments and pH-specific formulations. Custom particle sizes and solubility profiles are available for textile, cosmetics, or food industries. MOQs typically apply for bespoke orders.

Q: What testing protocols do quality blue indigo dye products undergo?

A: Products undergo HPLC analysis for purity and spectrophotometric color testing. Batch testing checks heavy metal content and allergen levels. Microbial testing ensures compliance with international safety standards.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.