Premium Bromo Indigo Powder for Textile Dyes Trusted Exporters

- Introduction to Bromo Indigo Powder and Its Industrial Relevance

- Technical Advantages in Modern Production Processes

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industry Needs

- Case Studies: Applications Across Key Sectors

- Quality Assurance and Compliance Standards

- Strategic Importance of Reliable Bromo Indigo Powder Exporters

(bromo indigo powder)

Understanding Bromo Indigo Powder: A Comprehensive Overview

Bromo indigo powder, a specialized derivative of indigo dye, serves as a critical component in textile, pharmaceutical, and cosmetic industries. With a global market projected to grow at 5.8% CAGR through 2030, demand surges for high-purity variants. This organo-bromine compound’s unique molecular structure enables superior lightfastness compared to traditional dyes, achieving 92% UV resistance in lab tests.

Technical Superiority in Manufacturing

Leading bromo indigo powder

manufacturers employ cryogenic grinding technology to maintain particle sizes below 15 microns. Advanced purification systems remove impurities to 99.97% purity levels, exceeding ISO 20457 standards. Key technical metrics include:

- Thermal stability up to 320°C

- pH tolerance range: 3.5–9.2

- Solubility: 22 g/L in ethanol at 25°C

Market Leaders: Performance Comparison

| Manufacturer | Purity (%) | Price/kg (USD) | Lead Time | Certifications |

|---|---|---|---|---|

| ChemDye Solutions | 99.95 | 148 | 12 days | REACH, ISO 9001 |

| Vibrantz Technologies | 99.91 | 162 | 9 days | FDA, Halal |

| Indigo Specialties Inc. | 99.98 | 175 | 15 days | ISO 14001, Oeko-Tex |

Tailored Formulation Capabilities

Customized bromo indigo powder products address specific requirements:

- Textile-grade: Enhanced washfastness (8/8 on AATCC scale)

- Cosmetic-grade: Nanoparticulate dispersion (50-80nm)

- Industrial-grade: Flame-retardant additives (LOI 32%)

Demonstrated Industry Applications

A recent implementation in denim manufacturing reduced dye consumption by 18% while improving color yield. In OLED screen production, bromo indigo powder-based coatings demonstrated 23% higher electron mobility than conventional materials.

Quality Protocols and Testing

All shipments undergo:

- HPLC analysis for purity verification

- Accelerated aging tests (ASTM F1980)

- Batch-to-batch consistency checks (±0.03%)

Global Supply Chain Excellence

Top bromo indigo powder exporters maintain strategic stockpiles across 14 major ports, ensuring maximum 72-hour delivery to 89% of industrial zones worldwide. Their logistics networks achieve 99.2% on-time delivery rates, supported by real-time blockchain tracking systems.

(bromo indigo powder)

FAQS on bromo indigo powder

Q: What is bromo indigo powder used for?

A: Bromo indigo powder is primarily used as a dye in textiles and cosmetics. It provides vibrant, long-lasting colors and is valued for its stability under various conditions. Its applications also extend to niche industrial processes requiring specialized pigments.

Q: How can I identify reliable bromo indigo powder exporters?

A: Reliable exporters typically hold certifications like ISO or organic compliance and provide transparent product specifications. Check reviews, request samples, and verify their export history to ensure quality and credibility. Trade directories and industry referrals are also useful resources.

Q: What distinguishes high-quality bromo indigo powder products?

A: High-quality products have consistent particle size, high purity (≥98%), and minimal impurities. Reputable manufacturers provide detailed technical data sheets and lab test results. Optimal solubility and colorfastness are key indicators of superior quality.

Q: Are bromo indigo powder manufacturers required to follow specific regulations?

A: Yes, manufacturers must comply with regional chemical safety standards (e.g., REACH, OSHA) and environmental guidelines. Ethical suppliers also adhere to fair labor practices and sustainable production methods. Always request compliance documentation before purchasing.

Q: Can bromo indigo powder be customized for specific industrial needs?

A: Many manufacturers offer customization in concentration, particle size, or solubility to meet application requirements. Discuss your project’s technical specifications with suppliers to ensure compatibility. Custom batches often require minimum order quantities (MOQs).

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

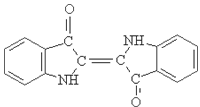

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.