Exploring the Traditional Process of Mixing Indigo Powder in China

The Art and Science of Mixing Indigo Powder A Journey into Traditional Chinese Dyeing Techniques

Indigo, a deep blue dye derived from the plant Indigofera, has been cherished for centuries, particularly in traditional Chinese textile practices. The process of mixing indigo powder highlights not only the artistic flair of artisans but also the intricate chemistry involved in creating vibrant hues that capture the essence of nature. This article explores the historical significance, modern applications, and the meticulous techniques involved in mixing indigo powder within the context of Chinese culture.

Historical Significance

The use of indigo in Chinese dyeing dates back to ancient times, making it one of the earliest known dyes utilized in textile production. Historical records indicate that indigo plants were cultivated as early as the Han Dynasty (206 BC – 220 AD). The dyeing techniques evolved over centuries, incorporating various methods of extraction and application. Indigo was not only valued for its beauty but also for its symbolism; the color blue represented purity and healing, deeply resonating with Chinese philosophies.

The Indigo Dyeing Process

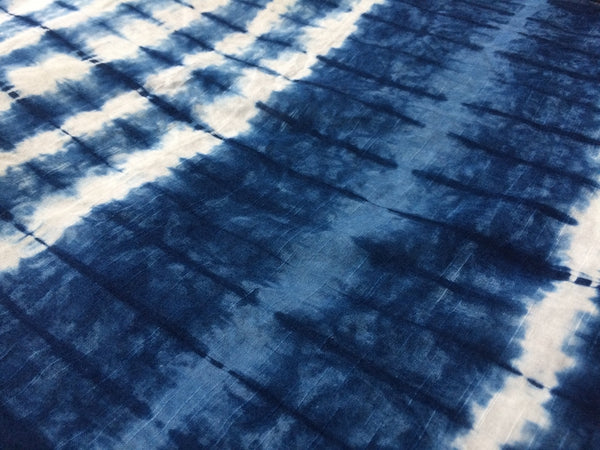

Mixing indigo powder involves a meticulous process that requires both skill and reverence for tradition. The basic components of indigo dyeing are the indigo plant, which produces the dye through fermentation, and a range of auxiliary materials. Artisans often begin by soaking the indigo leaves in water, allowing them to ferment and transform into a pigment known as indigo paste. Once the paste is ready, it is mixed with a reducing agent, typically lye or hydroxide, which helps to convert the solid dye into a soluble form that can adhere to fabrics.

The mixing process is crucial; it not only determines the shade of blue achieved but also the quality and durability of the dye. By adjusting the proportions of water, reducing agents, and indigo powder, dyers can create a spectrum of blues, from soft pastels to deep navy. This bespoke approach to dye mixing is a testament to the artisan’s experience and intuition, often honed through generations.

china mixing indigo powder

Modern Applications

While traditional methods remain prevalent, modern technology has also influenced how indigo dye is mixed and applied. Today, some artisans blend indigo powder with synthetic dyes to achieve more consistent results or to create shockingly vibrant colors not attainable through natural processes alone. Furthermore, advancements in dyeing technology have enabled a broader range of applications, including Ikat and batik techniques, where indigo is used not only as a dye but as a means of creating intricate patterns on fabrics.

In recent years, there has been a resurgence of interest in natural dyes, spurred by a growing awareness of environmental issues and the harmful effects of synthetic chemicals in textile production. Many contemporary designers and brands are returning to traditional indigo mixing techniques, celebrating the sustainability and unique aesthetics of natural dyeing.

The Cultural Connection

Indigo powder mixing is more than just a technical process; it is deeply embedded in the cultural identity of various regions in China, particularly in areas like Guizhou, which is renowned for its indigo-dyed textiles. The skill of mixing and dyeing with indigo has been passed down through generations, with each artisan adding their distinct touch to the practice. This connection to heritage fosters a strong sense of community, with workshops and festivals dedicated to promoting indigo dyeing and educating the public about its significance.

Conclusion

The art of mixing indigo powder is a fascinating intersection of history, culture, and science. It reflects centuries of tradition while adapting to modern influences. As artisans continue to honor the past and innovate for the future, the rich heritage of indigo dyeing remains an essential aspect of Chinese textiles, reminding us of the beauty that can emerge from the delicate balance of craftsmanship and nature. Whether in the form of a handcrafted garment or a piece of art, the deep blue hues of indigo carry with them stories of tradition, resilience, and creative expression that resonate profoundly within the fabric of Chinese culture.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.