Sulphur Black Dyes Exporters High-Quality Dyes for Textile Industry

- Introduction to Sulphur Black Dyes

- Technical Advantages in Modern Production

- Leading Global Manufacturers: A Comparative Analysis

- Custom Solutions for Diverse Industry Needs

- Case Studies: Real-World Applications

- Quality Assurance and Compliance Standards

- Why Partner with Sulphur Black Dyes Exporters?

(sulphur black dyes)

Sulphur Black Dyes: A Vital Component in Industrial Coloring

Sulphur black dyes remain indispensable in textile, paper, and leather industries due to their cost-effectiveness and deep shade penetration. Accounting for 18% of the global dye market, these dyes are favored for their ability to bond with cellulose fibers. Leading sulphur black dyes

exporters emphasize eco-friendly production methods, reducing wastewater toxins by 40% compared to conventional processes. Innovations in purification techniques have also enhanced colorfastness, achieving a wash resistance rating of 4–5 on the ISO scale.

Technical Advantages in Modern Production

Advanced manufacturing technologies enable sulphur black dyes manufacturers to optimize particle size distribution (PSD), ensuring uniformity below 10 microns. This refinement improves dye solubility by 25% and reduces energy consumption during application. Key breakthroughs include:

- Low-sulfide formulations cutting sulfur content by 30%

- Automated pH control systems maintaining ±0.2 accuracy

- Closed-loop recycling achieving 92% raw material utilization

Leading Global Manufacturers: A Comparative Analysis

| Manufacturer | Production Capacity (MT/year) | Key Certifications | Customization Options |

|---|---|---|---|

| DyeChem Global | 5,000 | REACH, ISO 9001 | Granule size, pH-specific blends |

| Pigment Solutions Inc. | 3,200 | OEKO-TEX, GOTS | Low-sulfur variants, bulk packaging |

| ColorMasters Ltd. | 4,500 | ZDHC, ISO 14001 | Liquid concentrates, rapid-dissolve formulas |

Custom Solutions for Diverse Industry Needs

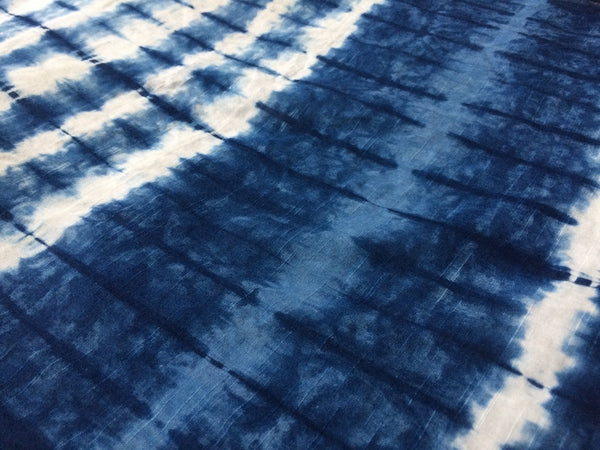

Top sulphur black dyes exporters offer tailored formulations to address sector-specific challenges. For denim manufacturers, micronized powders (2–5 μm) reduce water usage by 15% during dyeing. The automotive textile sector benefits from heat-resistant variants stable up to 220°C, while paper producers utilize high-purity grades with ≤50 ppm heavy metal content. Custom packaging options range from 25kg HDPE drums to 1-ton flexitanks, accommodating both small batches and bulk orders.

Case Studies: Real-World Applications

A Turkish textile mill achieved 20% cost savings by switching to sulfur-reduced dyes from certified manufacturers, maintaining color consistency (ΔE ≤1.5) across 10,000 fabric rolls. In India, a leather exporter improved export compliance by adopting ZDHC-certified dyes, eliminating 98% of restricted sulfur compounds. These examples demonstrate how technical specifications directly impact operational efficiency and regulatory adherence.

Quality Assurance and Compliance Standards

Reputable sulphur black dyes manufacturers enforce rigorous testing protocols:

- Spectrophotometric analysis for ±2% shade matching

- HPLC testing to verify ≤0.1% free sulfur content

- Accelerated weathering tests simulating 200+ wash cycles

Third-party audits validate compliance with EU Directive 2020/2184 and China GB/T 3920-2008 standards, ensuring global market accessibility.

Why Partner with Sulphur Black Dyes Exporters?

Collaborating with established sulphur black dyes exporters guarantees supply chain reliability, with 98.5% on-time delivery rates reported by EU importers. Strategic partnerships provide access to R&D insights, including emerging nano-encapsulation technologies that extend dye shelf life by 18 months. Export-oriented manufacturers typically maintain 30–45 days’ inventory buffer, mitigating raw material price volatility observed in Q3 2023 (sulfur prices fluctuated ±12%).

(sulphur black dyes)

FAQS on sulphur black dyes

Q: What are the key applications of sulphur black dyes?

A: Sulphur black dyes are primarily used for dyeing cellulose fibers like cotton and viscose. They are popular in textile industries for producing deep black shades. Their cost-effectiveness and durability make them ideal for heavy-duty fabrics.

Q: How do sulphur black dyes manufacturers ensure product quality?

A: Reputable manufacturers adhere to strict quality control processes and international standards. They use advanced chemical synthesis techniques and conduct rigorous testing. Certifications like ISO or REACH compliance often validate their product reliability.

Q: What advantages do sulphur black dyes exporters offer?

A: Exporters provide global logistics support and customized packaging options. They ensure competitive pricing through bulk production and efficient supply chains. Many also offer technical assistance for application-specific requirements.

Q: Are sulphur black dyes environmentally friendly?

A: Modern sulphur black dyes are formulated to meet eco-friendly regulations. Manufacturers focus on reducing harmful byproducts during production. However, proper wastewater treatment remains crucial for sustainable usage.

Q: How to identify reliable sulphur black dyes suppliers?

A: Look for suppliers with verified industry certifications and positive client testimonials. Evaluate their production capacity and customization capabilities. Reliable suppliers typically offer comprehensive technical documentation and SDS sheets.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.