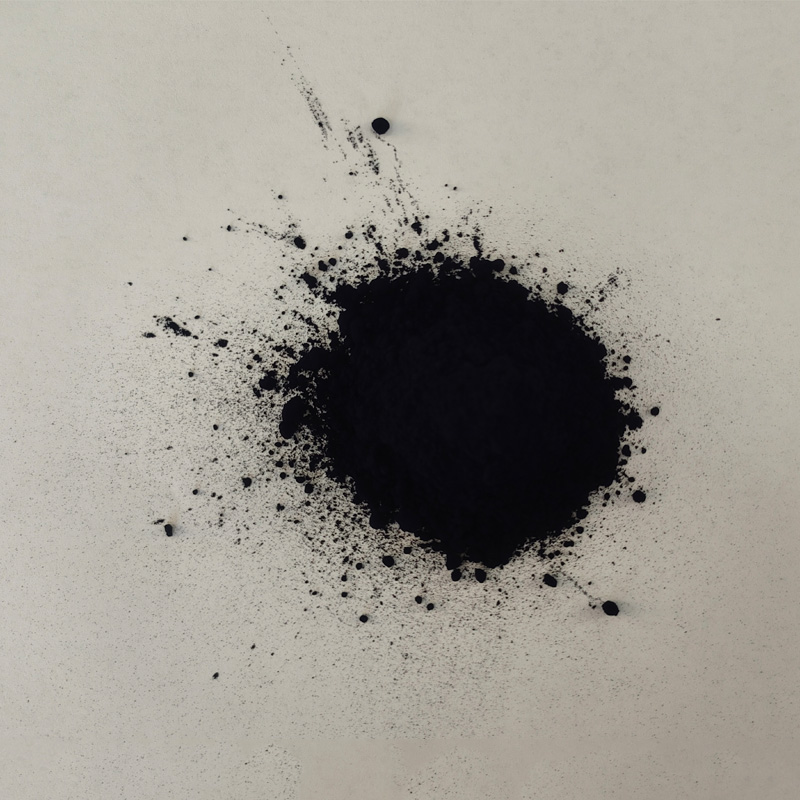

oem source for indigo dye

Exploring OEM Sources for Indigo Dye A Sustainable Approach

Indigo dye, renowned for its deep blue hue, has been a cornerstone of textile production for centuries. Originating from natural sources, particularly the indigo plant, the dye has found a significant place in modern manufacturing. With the rise of environmentally conscious practices, Original Equipment Manufacturers (OEMs) are increasingly turning their attention toward sustainable sources of indigo dye to meet the demands of eco-friendly consumers.

Exploring OEM Sources for Indigo Dye A Sustainable Approach

One of the most promising trends in the indigo dye industry is the shift towards organic farming and sustainable sourcing. OEMs are increasingly collaborating with farmers who cultivate indigo plants using organic practices. This approach not only supports local economies but also reduces the carbon footprint associated with synthetic dye production. Additionally, the use of natural indigo enhances the quality of the dyed fabrics, as they tend to be softer and more breathable compared to their synthetic counterparts.

oem source for indigo dye

Innovative technologies have also played a significant role in improving the efficiency of indigo dye extraction. Techniques such as microbial fermentation are being explored to produce indigo in a more sustainable manner. This method utilizes microorganisms to convert precursors into indigo, resulting in a lower environmental impact compared to traditional chemical processes.

Moreover, the rise of the circular economy has influenced how OEMs source indigo dye. Many companies are now focused on recycling and reusing dye, which not only minimizes waste but also lowers production costs. By integrating these practices, OEMs can ensure a more sustainable supply chain while appealing to environmentally conscious consumers.

As the demand for sustainable textiles continues to grow, OEMs focusing on natural indigo sources will have a competitive advantage. Brands that prioritize eco-friendly practices are likely to capture the attention of a discerning market that increasingly values transparency and sustainability.

In conclusion, the exploration of OEM sources for indigo dye embodies a significant shift towards sustainable practices in the textile industry. By embracing organic farming, innovative extraction techniques, and recycling initiatives, OEMs can provide high-quality, eco-friendly dyes that meet the needs of modern consumers. This not only contributes to environmental preservation but also fosters a more responsible textile industry, paving the way for a future where fashion and sustainability coexist harmoniously.

-

Thermal Stability Analysis of Bromo Indigo Pigments

NewsJun.06,2025

-

Sulphur Black Dye Oxidation Process Optimization

NewsJun.06,2025

-

Lightfastness Testing of Bromo Indigo Dyed Denim

NewsJun.06,2025

-

Granule Size Distribution and Jeans Color Uniformity

NewsJun.06,2025

-

Gradient Dyeing Methods with Indigo Blue Granules

NewsJun.06,2025

-

Dyeing Temperature Effects on Sulphur Black Color Fastness

NewsJun.06,2025

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.