Finding Reliable Sources for Sulfur Black Manufacturing and Its Applications

The Evolution of Sulfur Black Manufacturing A Deep Dive

Sulfur Black, a chemical compound widely used in the dyeing industry, is a staple for producing deep black shades on various textiles and materials. Its unique properties and effectiveness have made it a preferred choice for manufacturers and consumers alike. This article explores the history, production processes, applications, and environmental considerations surrounding Sulfur Black manufacturing.

Historical Background

The origins of Sulfur Black can be traced back to the early 19th century when chemists began experimenting with sulfur compounds for textile dyeing. The introduction of synthetic dyes marked a significant evolution in the dyeing industry, as they offered a more consistent and vibrant palette. By the late 1800s, Sulfur Black emerged as a cost-effective and efficient option for achieving rich black hues on cotton and other fibers. Its ability to bond with fibers during the dyeing process outlined a new chapter in textile manufacturing.

Production Processes

The manufacturing of Sulfur Black involves several chemical reactions, predominantly using substances such as sulfur, sodium sulfide, and various organic compounds. The process typically begins with the sulfuration of organic intermediates, followed by oxidation to form the final dark pigment.

1. Sulfuration The initial step involves heating the organic intermediate with sulfur, leading to the formation of polysulfide compounds. This step is crucial as it determines the quality and shade of the final product.

2. Oxidation The polysulfide compounds are then oxidized, often using sodium hypochlorite or other oxidizing agents, which results in the dark, stable dye that can be applied to various materials.

3. Purification The crude Sulfur Black may undergo purification processes to remove any impurities and to ensure the product's dyeing efficiency and safety for consumer use.

4. Finishing The final product is then dried and packaged for distribution. Care is taken during this process to maintain the quality of the dye and prevent degradation.

Applications

Sulfur Black is predominantly used in the textile industry, particularly for dyeing cotton, wool, and synthetic fibers

. Its ability to produce a rich, long-lasting black color has made it popular forsulfer black manufacturer

1. Denim One of the main applications of Sulfur Black is in denim production, giving jeans their iconic black coloration while maintaining the fabric's strength and durability.

2. Industrial Textiles This dye is also used in various industrial applications such as automotive upholstery, workwear, and other textiles requiring robust dyeing solutions.

3. Non-textile Products Beyond textiles, Sulfur Black is utilized in the manufacturing of some plastics, leather, and rubber products, further showcasing its versatility.

Environmental Considerations

As the demand for Sulfur Black continues to rise, so does the scrutiny surrounding its environmental impact. The manufacturing of synthetic dyes, including Sulfur Black, has been criticized for generating hazardous waste and polluting water resources. A growing number of regulations focus on minimizing waste production and improving the sustainability of dyeing processes.

In response to these challenges, manufacturers are exploring eco-friendly practices, such as

- Using Alternative Raw Materials Research is being conducted to replace harmful chemicals with more sustainable alternatives.

- Water Management Implementing closed-loop systems in dyeing processes to recycle water and reduce consumption.

- Waste Treatment Technologies Developing effective waste management practices to treat and reuse by-products from the dyeing process.

Conclusion

Sulfur Black has become an indispensable component of the textile industry and continues to evolve through technological advancements and environmental considerations. As manufacturers strive for a balance between efficiency, product quality, and sustainability, the future of Sulfur Black manufacturing looks promising. Continued innovation in production processes and a commitment to environmental stewardship will likely shape the next chapter in this dynamic industry, ensuring that Sulfur Black remains a cornerstone of textile dyeing for years to come.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

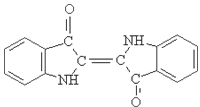

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.