indigo dyeing factories

The Rich History and Modern Revival of Indigo Dyeing Factories

Indigo dyeing has a storied tradition that dates back thousands of years, rooted in various cultures across the globe. From the ancient civilizations of India to contemporary textile industries in Japan and Africa, indigo has played a vital role in fabric dyeing practices. The resurgence of interest in traditional indigo dyeing techniques and sustainable practices has led to new growth in indigo dyeing factories, combining age-old methods with modern innovation.

Historical Significance of Indigo

Indigo, derived from the leaves of the indigo plant, was historically processed through intricate fermentation and extraction methods. The deep, rich blue produced by this dye is unique and has been revered for its vibrancy and durability. In ancient India, the use of indigo was closely linked to trade, with indigo-dyed textiles becoming sought-after commodities along the Silk Road. Similarly, in West Africa, indigo dyeing formed an integral part of cultural identity and expression.

Traditionally, indigo was often considered a symbol of wealth and status. The complexity of the dyeing process itself added to the textile's allure. Craftspeople perfected their skills over generations, leading to the development of unique regional styles and techniques.

The Craft of Indigo Dyeing

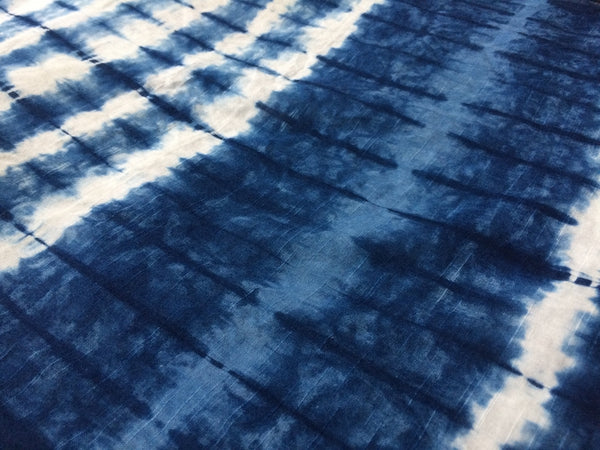

The process of indigo dyeing is labor-intensive, requiring a deep understanding of the chemistry behind the dye. The leaves of the indigo plant are harvested and fermented to produce a liquid dye known as indigo vat. The dyeing process involves several stages, including soaking, oxidation, and rinsing, which can be time-consuming but results in the captivating hues characteristic of indigo-dyed fabrics.

In modern indigo dyeing factories, artisans blend traditional methods with contemporary technology to optimize production while maintaining craftsmanship. Many factories today utilize eco-friendly practices, reducing the environmental impact associated with chemical dyes. This sustainable approach not only resonates with consumers who are increasingly concerned about environmental issues but also revives ancient methods that are in danger of being lost.

indigo dyeing factories

Modern Indigo Dyeing Factories

Today, indigo dyeing factories can be found around the world, from small artisanal workshops to larger industrial plants. These factories often serve as cultural hubs, where visitors can witness the dyeing process firsthand. They offer workshops, allowing enthusiasts to engage with the craft and learn about its history and applications.

In countries like Japan, the tradition of shibori, a method of resist dyeing, has become popularized, leading to a revitalization of indigo dyeing techniques. Factories that specialize in this art have gained international recognition, promoting the cultural heritage behind their products. Each piece created in these workshops tells a story, often echoing ancient traditions while catering to modern aesthetics.

The Future of Indigo Dyeing

The future of indigo dyeing is bright, with a growing appreciation for handmade, sustainable textiles. Consumers are increasingly leaning towards eco-conscious fashion, seeking products that align with their values. This shift drives demand for indigo-dyed textiles, allowing traditional factories to thrive and adapt.

Moreover, collaborations between designers and indigo artisans are evolving, as fashion brands seek to incorporate traditional techniques into their collections. This synergy not only elevates the visibility of indigo dyeing but also ensures that artisans receive fair compensation for their craft.

In conclusion, indigo dyeing factories represent a confluence of artistry, tradition, and sustainability. As we move forward, it is crucial to preserve these practices, ensuring that they continue to play an essential role in our cultural fabric. Whether through fashion, home textiles, or art, the deep blue of indigo will remain a poignant testament to human creativity and the timeless connection between nature and culture.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.