Top Suppliers for Sulfur Dyes in the Textile Industry and Their Offerings

The Growing Demand for Sulfur Dyes and Reliable Suppliers

The textile industry is a vital part of the global economy, and one of the critical components that contribute to its vibrancy is the use of dyes. Among the various types of dyes available, sulfur dyes have gained considerable popularity due to their remarkable properties and versatility. Given the increasing demand for sulfur dyes in textiles, identifying and collaborating with reliable suppliers has become a significant focus for manufacturers.

Understanding Sulfur Dyes

Sulfur dyes, as the name suggests, are synthetic dyes primarily derived from sulfur. Known for their affordability and high level of colorfastness, these dyes are particularly suited for dyeing cotton and other cellulose fibers. The dyeing process typically involves creating a soluble form of the dye using a reductive agent, which is then applied to the fabric. Once the dyeing process is complete, the fabric is subjected to oxidation to fix the dye—leading to vibrant colors that resist fading, even after multiple washes.

Another notable advantage of sulfur dyes is their ability to produce a wide spectrum of colors. From deep blacks to bright shades, they can meet the diverse aesthetic demands of the fashion industry. Their resistance to light and washing makes them ideal for producing textiles that require durability, such as workwear, sportswear, and home furnishings.

The Rise in Demand

As sustainable practices gain traction across industries, sulfur dyes are coming to the forefront as an eco-friendly dyeing option. They require less water in the dyeing process compared to other dye types and often do not produce harmful wastewater. This reduced environmental impact makes them a more appealing choice for textile manufacturers aiming to reduce their ecological footprint.

Furthermore, the increasing popularity of organic fabrics and sustainable clothing lines has contributed to the rise in demand for sulfur dyes. As manufacturers navigate consumer preferences for eco-friendly products, the need for dyes that align with these values has become paramount. This growing interest translates into an increased focus on sourcing sulfur dyes from reliable suppliers, ensuring high-quality products that meet both industry standards and consumer expectations.

Selecting Reliable Suppliers

sulfur dyes suppliers

With the demand for sulfur dyes on the rise, the importance of choosing reliable suppliers cannot be understated. Manufacturers looking to partner with dye suppliers must consider several key factors

1. Quality Assurance Quality should be the foremost consideration. Suppliers must provide consistent dye quality, as variations can affect the final product's appearance and performance. Requesting samples and testing the dyes on fabric can ascertain quality before making long-term commitments.

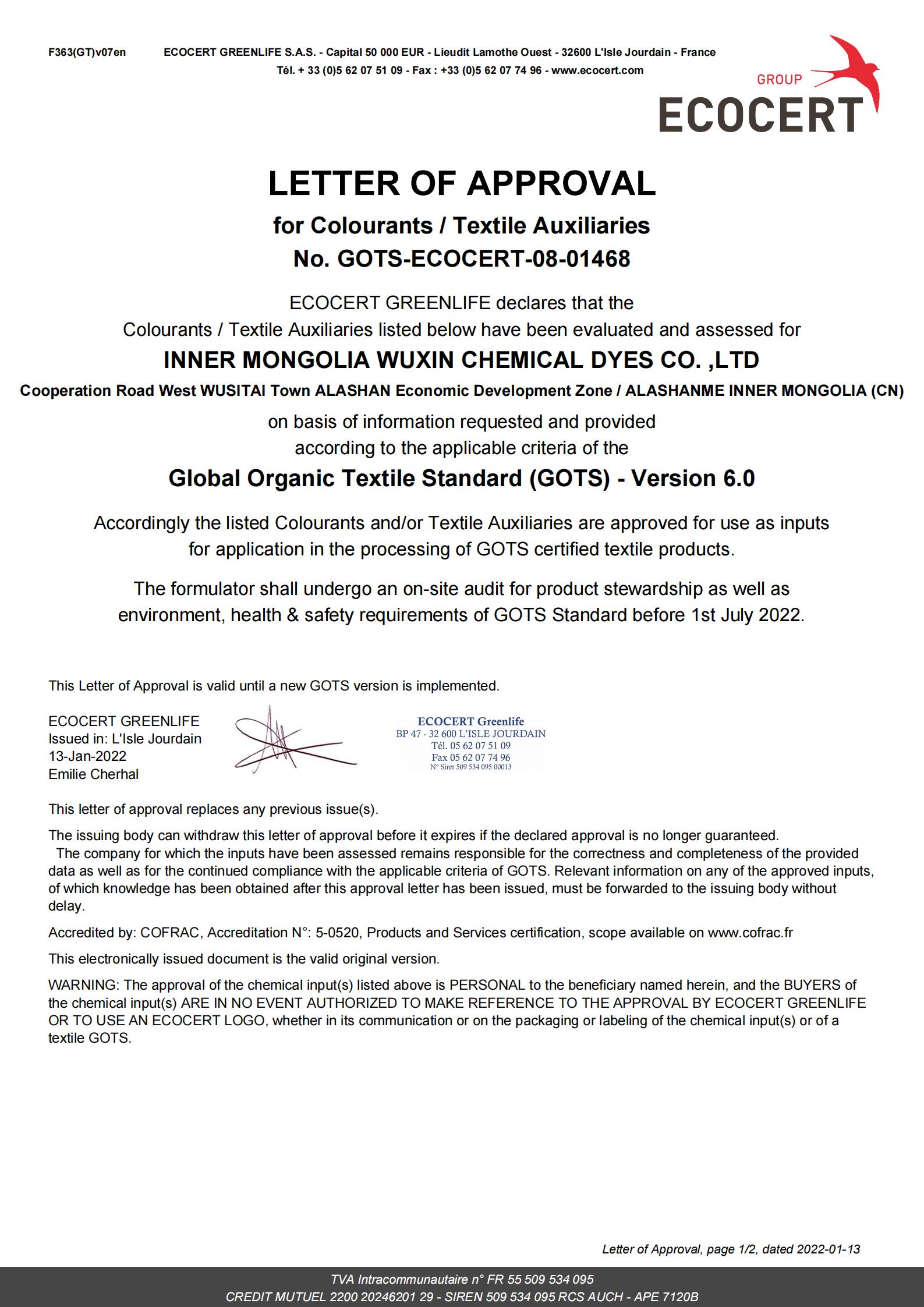

2. Compliance and Sustainability Suppliers should adhere to regulations surrounding chemical use and environmental impact. Certifications such as Oeko-Tex or GOTS can indicate that a supplier operates sustainably and complies with safety standards, which is increasingly important in the eco-conscious market.

3. Product Range and Innovation Reliable suppliers will offer a diverse range of sulfur dyes with the ability to create custom shades to meet specific requirements. An innovative supplier will also keep pace with trends, ensuring that they can meet the evolving needs of the market.

4. Customer Service Strong customer service support is essential. Suppliers that provide responsive communication, technical support, and transparent operations contribute to smoother business transactions and foster strong long-term partnerships.

5. Reputation and Reliability Researching a supplier’s reputation in the industry, including customer reviews and case studies, can provide insights into their reliability and performance. Engaging with other manufacturers who have experience with suppliers can yield valuable information.

Conclusion

As the textile industry continues to embrace sustainable practices, sulfur dyes are poised to play a pivotal role in meeting the demands of the modern market. Manufacturers must prioritize finding reliable suppliers who can provide high-quality, environmentally friendly products and support their growth in an increasingly competitive landscape. By carefully selecting partners in the supply chain, textile manufacturers can ensure they meet consumer expectations while contributing to a more sustainable future.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.