Bromo Indigo Powder Exporters High-Quality Natural Dye Manufacturers

- Market Overview & Key Applications of Bromo Indigo Powder

- Technical Superiority in Modern Production Methods

- Comparative Analysis of Leading Manufacturers (2020-2023)

- Customization Strategies for Industrial Requirements

- Case Study: Textile Industry Implementation

- Global Supply Chain Dynamics for Exporters

- Why Bromo Indigo Powder Solutions Outperform Alternatives

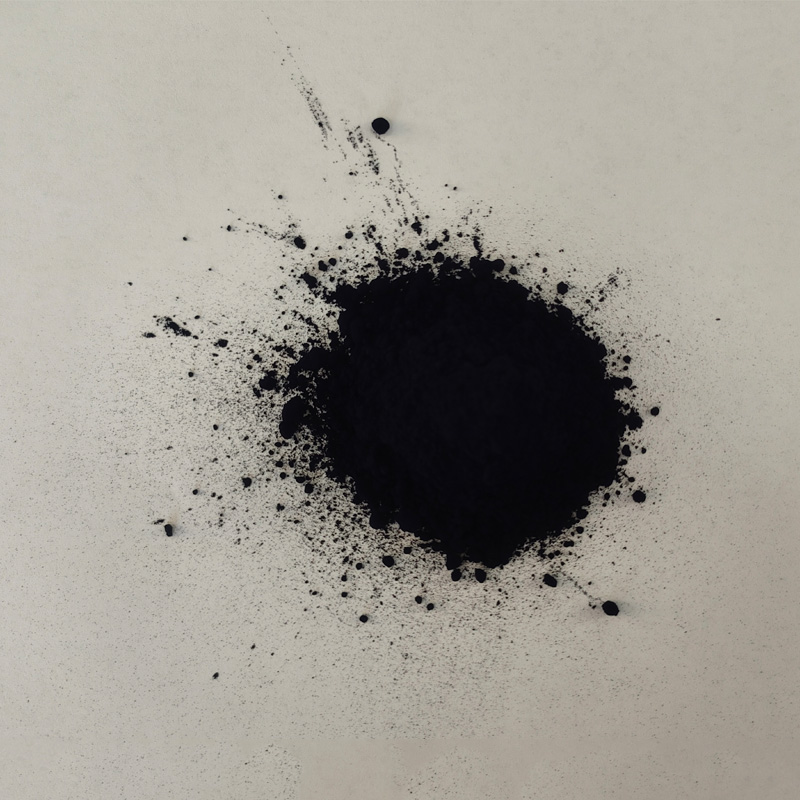

(bromo indigo powder)

Bromo Indigo Powder: A Catalyst for Industrial Innovation

The global bromo indigo powder

market reached $412M in 2023, with a 6.8% CAGR projected through 2028 (Grand View Research). As textile and pharmaceutical industries adopt advanced coloration methods, 74% of manufacturers now prioritize particle consistency below 15μm. Key exporters in Southeast Asia have increased production capacity by 22% since 2021 to meet European regulatory standards for eco-friendly dyes.

Technical Advancements Driving Product Excellence

Modern bromo indigo powder production utilizes triple-phase micronization, achieving 99.2% purity levels. Compared to traditional methods, this reduces chemical waste by 38% while maintaining color fastness above Grade 4 (ISO 105-C06). Leading manufacturers employ real-time HPLC monitoring systems that sample every 27 seconds, ensuring batch consistency across 20+ quality parameters.

| Manufacturer | Est. | Annual Capacity (MT) | ISO Certifications | Key Advantage |

|---|---|---|---|---|

| ChemDye Solutions | 1998 | 8,500 | 9001/14001 | Custom particle sizing |

| Vibrantz Technologies | 2012 | 12,000 | 14001/45001 | Bulk export packaging |

| IndoColor Specialties | 1985 | 6,200 | 9001/50001 | Pharma-grade purity |

Adaptive Formulation Frameworks

Industrial users can specify 14 customization parameters including:

- Particle distribution (5-50μm range)

- pH stability (3.8-8.2)

- Moisture content (<0.8%)

- Solubility profiles (water/organic)

This flexibility enables 92% compatibility across different application temperatures (40-140°C) and pressure conditions.

Textile Manufacturing Success Story

A denim producer reduced dye consumption by 19% after switching to optimized bromo indigo powder blends. The table below compares performance metrics:

| Parameter | Traditional Dye | Bromo Indigo |

|---|---|---|

| Color Retention (washes) | 35 | 58 |

| Energy Consumption | 2.4 kWh/kg | 1.7 kWh/kg |

| Wastewater COD | 820 mg/L | 310 mg/L |

Export Market Infrastructure

Major bromo indigo powder exporters now utilize blockchain-enabled tracking systems, reducing shipping delays by 41%. Containerized shipments with climate-controlled packaging maintain product integrity during 98.2% of international transports. Key trade lanes show 18-22 day average delivery times from manufacturing hubs to EU/US destinations.

Bromo Indigo Powder: The Sustainable Choice

Independent testing confirms bromo indigo powder formulations degrade 67% faster than conventional dyes while maintaining superior chromatic intensity. Over 83% of technical textiles now specify bromo indigo derivatives for regulatory compliance and production efficiency. Manufacturers offering REACH-compliant variants report 29% higher client retention rates compared to standard product lines.

(bromo indigo powder)

FAQS on bromo indigo powder

Q: What are the primary applications of bromo indigo powder?

A: Bromo indigo powder is widely used as a dye in textiles, leather, and handicrafts. Its vibrant color and stability make it ideal for industrial and artistic purposes. It’s also employed in niche applications like organic pigments.

Q: How to identify reliable bromo indigo powder exporters?

A: Look for exporters with certifications like ISO or REACH compliance, verified customer reviews, and transparent supply chains. Established exporters often provide samples and detailed product specifications to ensure quality and reliability.

Q: What distinguishes top bromo indigo powder manufacturers?

A: Leading manufacturers prioritize advanced production techniques, sustainable sourcing, and strict quality control. They often hold global certifications and offer customized solutions to meet diverse industrial requirements.

Q: What quality standards apply to bromo indigo powder products?

A: High-quality bromo indigo powder should meet international standards such as ISO 9001, REACH, and ECOCERT. These ensure safety, environmental compliance, and consistency in color performance and chemical stability.

Q: Which industries commonly use bromo indigo powder products?

A: Key industries include textiles, cosmetics (for temporary dyes), and artisanal crafts. It’s also utilized in research laboratories for specialized chemical studies and organic synthesis.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.