indigo synthetic factories

The Rise of Indigo Synthetic Factories A Modern Revolution in Dye Production

In the vibrant world of textiles, indigo dye has long been celebrated for its rich, deep blue color, a staple in fashion from denim jeans to traditional garments across various cultures. Historically derived from natural sources, the process of producing indigo dye has evolved significantly, especially with the advent of synthetic options. Today, indigo synthetic factories are transforming the industry, promising a sustainable and cost-effective solution amid growing environmental concerns.

The Historical Context of Indigo Dye

Indigo dye's history dates back thousands of years, with its earliest uses traced to ancient civilizations in India and Egypt. The dye, traditionally sourced from indigo plants like Indigofera tinctoria, produces a stunning blue hue, but the extraction process is labor-intensive and time-consuming. Over the years, as global demand for blue textiles surged, the challenges of natural indigo production became apparent. The shift from natural to synthetic indigo began in the late 19th century, pioneered by German chemists who developed a chemical process to produce indigo artificially, revolutionizing dye manufacturing.

The Need for Synthetic Indigo

The drive towards synthetic indigo production was propelled by various factors. Natural indigo is often more expensive, less consistent in quality, and heavily reliant on agricultural practices that can be compromised by climatic changes. Additionally, the environmental implications of cultivation—such as land use, water consumption, and the potential for chemical runoff—have raised concerns among eco-conscious consumers and brands alike.

Synthetic indigo, on the other hand, can be produced at a larger scale with a more predictable output. It is synthesized using a combination of chemical processes, primarily involving aniline and other petrochemical derivatives. This method not only decreases reliance on agricultural cycles but also allows for control over the dye's qualities and production efficiencies.

The Role of Indigo Synthetic Factories

indigo synthetic factories

The establishment of indigo synthetic factories marks a significant milestone in the textile and dye industry. These factories are equipped with advanced technologies that streamline the dye production process, minimizing waste and energy consumption. By utilizing techniques such as closed-loop systems, where chemicals are reused and treated to reduce environmental impact, synthetic indigo factories address many ecological concerns associated with traditional dyeing methods.

Furthermore, these factories have the ability to create a wider range of shades and qualities for various applications, ensuring that the textile industry can meet evolving consumer demands. The ability to produce indigo at scale also means reduced costs for manufacturers, which can ultimately lower prices for consumers while maintaining profitability for brands.

Sustainability and Future Prospects

One of the most compelling arguments for the transition to synthetic indigo is sustainability. With increasing scrutiny over environmental practices, many clothing brands are prioritizing eco-friendly materials and production methods. Synthetic indigo aligns with these values by offering a solution that can potentially reduce the carbon footprint associated with denim production.

However, the journey is not without challenges. The production of synthetic indigo relies on petrochemical sources, raising questions about the long-term sustainability of such practices. The industry is now exploring bioengineering techniques, where microorganisms or plants might be utilized to produce indigo-like compounds, thus lessening dependencies on fossil fuels and minimizing environmental impact.

Conclusion

The rise of indigo synthetic factories represents a pivotal shift in the textile industry. As consumers increasingly demand transparency and sustainability, these factories provide an innovative solution that balances the need for quality and efficiency while addressing environmental concerns. The future of indigo dye production promises to be as rich and diverse as the color itself, blending tradition with modern ingenuity. The challenge remains to refine these methods further, ensuring sustainability at every step of the dyeing process, paving the way for a more sustainable and responsible fashion industry.

-

The Timeless Art of Denim Indigo Dye

NewsJul.01,2025

-

The Rise of Sulfur Dyed Denim

NewsJul.01,2025

-

The Rich Revival of the Best Indigo Dye

NewsJul.01,2025

-

The Enduring Strength of Sulphur Black

NewsJul.01,2025

-

The Ancient Art of Chinese Indigo Dye

NewsJul.01,2025

-

Industry Power of Indigo

NewsJul.01,2025

-

Black Sulfur is Leading the Next Wave

NewsJul.01,2025

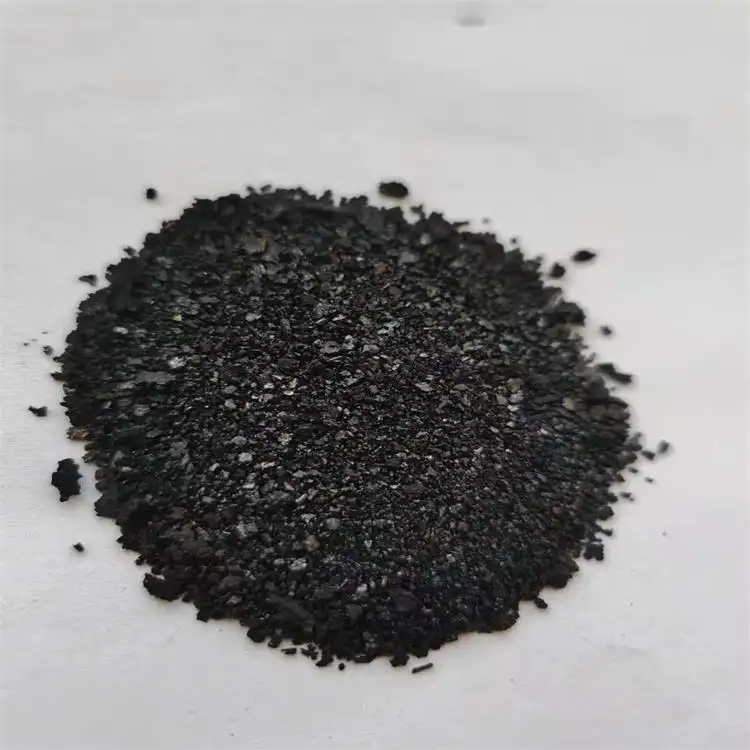

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.