Exploring the Benefits of OEM Indigo Dye for Sustainable Textile Production

The Role of OEM Indigo Dye Vats in Modern Textile Production

Indigo, one of the oldest dyes in the world, has a rich history that dates back thousands of years. With its deep blue color, indigo has been a staple in textile production, especially in the manufacturing of denim. As the textile industry continues to evolve, Original Equipment Manufacturer (OEM) indigo dye vats have become increasingly essential in optimizing production processes while meeting modern environmental and quality standards.

Understanding OEM Indigo Dye Vats

OEM, or Original Equipment Manufacturer, refers to companies that produce goods that are then marketed by another manufacturer. In the context of indigo dye vats, OEMs provide specialized equipment designed for dyeing fabrics with indigo in a way that is efficient, consistent, and environmentally friendly. These vats are integral to the dyeing process, allowing for precise temperature control, optimal dye absorption, and effective management of indigo's unique dye properties.

Indigo dyeing involves a fermentation process that requires careful monitoring of several variables, including temperature, pH balance, and dye concentration. OEM indigo dye vats are engineered to provide this control, utilizing advanced technology to enhance the dyeing process. This ensures that the final product consistently meets the high standards demanded by both manufacturers and consumers.

The Advantages of Using OEM Indigo Dye Vats

1. Consistency and Quality Control One of the primary benefits of utilizing OEM indigo dye vats is their ability to produce uniformly dyed fabrics. Traditional methods can result in inconsistent colors due to the variability in human handling and environmental factors. With fixed parameters and automated processes, OEM dye vats provide a level of precision that is difficult to achieve manually.

2. Efficiency In the fast-paced fashion and textile industry, time is a crucial factor. OEM dye vats allow for a faster dyeing process compared to traditional methods, which can be labor-intensive and time-consuming. This efficiency reduces lead times, enabling brands to respond more quickly to market demands.

oem indigo dye vat

3. Environmental Considerations The textile industry has faced criticism for its environmental impact, especially concerning water and chemical usage. OEM manufacturers are increasingly focusing on eco-friendly practices. Modern indigo dye vats incorporate closed-loop systems that minimize water waste and prevent the release of harmful chemicals into the environment. Some vats even utilize renewable energy sources, aligning with the sustainability goals of many textile companies.

4. Cost-Effectiveness While the initial investment in OEM indigo dye vats may be significant, the long-term cost savings are substantial. By reducing waste, improving efficiency, and minimizing errors, these systems lower overall production costs. This economic advantage is particularly appealing to manufacturers looking to enhance their competitiveness in the global market.

5. Innovation and Customization OEMs are often at the forefront of technological innovations in textile production. They can provide custom solutions tailored to specific manufacturing needs, such as varying fabric types or unique dyeing patterns. This flexibility allows for creativity in design while maintaining the operational efficacy.

Challenges and Considerations

Despite the numerous benefits, companies considering the transition to OEM indigo dye vats must also address certain challenges. The transition requires a significant initial investment, both financially and in training personnel to operate advanced machinery. Additionally, sourcing high-quality indigo dye and ensuring its sustainability can pose challenges in maintaining ethical manufacturing practices.

The Future of Indigo Dyeing

As the textile industry continues to embrace sustainability and technological advancements, the role of OEM indigo dye vats will likely expand. Innovations in dyeing technology, coupled with an increasing consumer demand for eco-friendly products, suggest a promising future for indigo dyeing processes.

In conclusion, OEM indigo dye vats represent a significant advancement in the textile industry, offering numerous advantages in terms of quality, efficiency, and sustainability. As manufacturers look for ways to enhance their operations while responding to ethical consumer demands, the adoption of these innovative solutions will be crucial. The blue hue of indigo may thus not only be a testament to the past but a key to a more sustainable future in textile production.

-

Thermal Stability Analysis of Bromo Indigo Pigments

NewsJun.06,2025

-

Sulphur Black Dye Oxidation Process Optimization

NewsJun.06,2025

-

Lightfastness Testing of Bromo Indigo Dyed Denim

NewsJun.06,2025

-

Granule Size Distribution and Jeans Color Uniformity

NewsJun.06,2025

-

Gradient Dyeing Methods with Indigo Blue Granules

NewsJun.06,2025

-

Dyeing Temperature Effects on Sulphur Black Color Fastness

NewsJun.06,2025

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

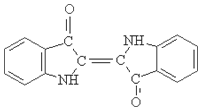

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.