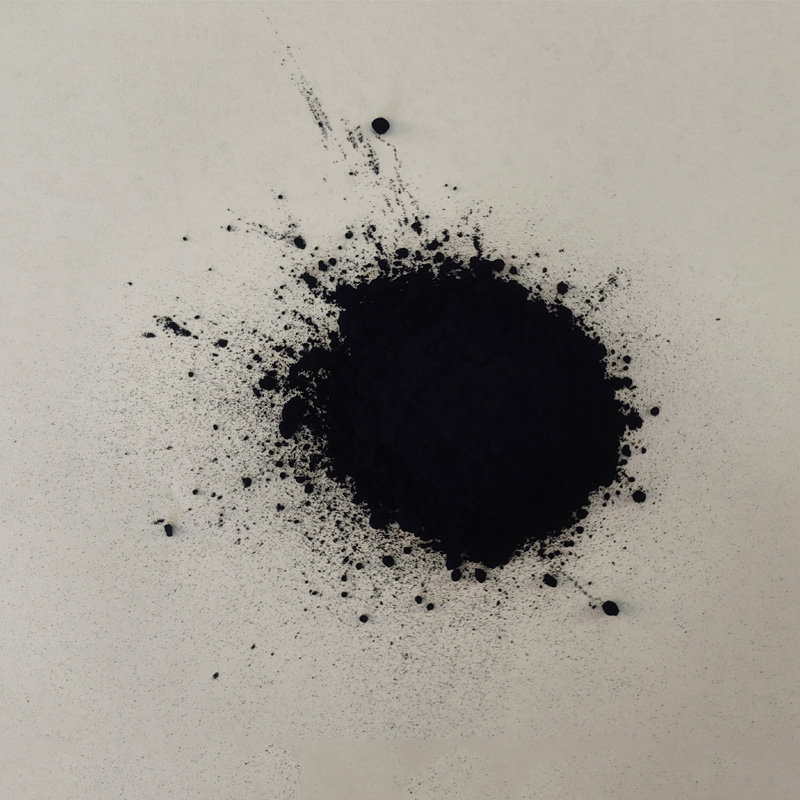

vat dye indigo manufacturers

The Role of VAT Dye Indigo Manufacturers in the Textile Industry

Indigo, with its rich and vibrant hues, has been a fundamental dye in the textile industry for centuries. Among various indigo dyeing processes, the Vat dyeing method stands out due to its remarkable colorfastness and versatility. The production of VAT indigo dye involves a specific chemical process that allows it to bond effectively with textile fibers, resulting in deep and enduring colors. This article explores the significance of VAT dye indigo manufacturers within the textile industry, highlighting their contributions, challenges, and future prospects.

Understanding VAT Dye Indigo

VAT dyes are a class of dyes that are insoluble in water and require a reduction process to become soluble, allowing them to penetrate the fabric. Once the fabric is dyed, it is exposed to air, restoring the dye’s insoluble form and locking in the color. Indigo, specifically, is one of the oldest dyes used in human history, known for its unique ability to produce varying shades of blue based on the concentration and application method.

VAT dye indigo is prized for its exceptional colorfastness, meaning that it resists fading from washing and light exposure. This characteristic makes it particularly valuable in the manufacturing of denim, workwear, and various other textiles that require durability. The process of creating VAT indigo involves significant chemical expertise and precision, underscoring the critical role of manufacturers in this niche market.

The Role of Manufacturers

VAT dye indigo manufacturers are vital to the functioning of the textile industry. They not only produce the dye but also ensure its quality, consistency, and adherence to safety and environmental regulations. The production process typically involves several stages, including

1. Synthesis of Indigo The base chemical structure of indigo is synthesized from precursor materials. This process demands careful control of chemical reactions to ensure high purity and optimal yield.

2. Reduction Process The dye is then reduced to a soluble form, often using reducing agents like sodium hydrosulfite. This process transforms the pigment and enables dye uptake by the fabric.

3. Quality Control Quality assurance is pivotal, as manufacturers must consistently produce dyes that meet industry standards. This involves rigorous testing for color consistency, solubility, and performance.

vat dye indigo manufacturers

4. Sustainability Practices In light of increasing environmental concerns, many VAT dye indigo manufacturers are adopting sustainable practices. This includes using eco-friendly reducing agents, recycling water, and minimizing waste in the dyeing process.

Challenges Faced by Manufacturers

Despite the vital role VAT dye indigo manufacturers play, they face several challenges in the industry. One major challenge is the environmental impact of dye production. Traditional dyeing processes can lead to significant water pollution and require substantial water usage, prompting public scrutiny and regulatory pressure.

Moreover, the increasing popularity of synthetic dyes, which are often cheaper and easier to produce, poses a competitive threat to VAT indigo manufacturers. As a result, many are exploring innovative solutions to reduce production costs while maintaining quality.

The volatility of raw materials can also impact production, as price fluctuations and supply chain disruptions often affect the cost margins of manufacturers. Sustainable sourcing of raw materials and efficient supply chain management are therefore critical for maintaining operational stability.

Future Prospects

Looking ahead, VAT dye indigo manufacturers have exciting opportunities driven by the growing demand for sustainable textile products. As consumers become more environmentally conscious, there is an increasing preference for natural and eco-friendly dyes. This trend is spurring manufacturers to invest in sustainable technologies and practices that align with market demand.

Furthermore, advances in biotechnological methods for dye production could revolutionize the industry. Innovations, such as bio-based reduction processes or the use of genetically engineered organisms for indigo production, could potentially reduce reliance on traditional chemical processes, improving both environmental and economic outcomes.

In conclusion, VAT dye indigo manufacturers play an indispensable role in the textile industry, embodying the fusion of tradition and modernity. While they face numerous challenges, their commitment to quality, sustainability, and innovation positions them strategically for future growth. As the industry continues to evolve, these manufacturers will remain at the forefront of delivering vibrant and durable textile solutions that meet the demands of both consumers and the environment.

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

-

Indigo Dyeing for Daily Life

NewsMay.07,2025

-

Indigo Dye Production and Its Growing Demand

NewsMay.07,2025

-

Color That Lasts

NewsMay.07,2025

-

Bromo Indigo for Modern Use

NewsMay.07,2025

-

Blue From Nature

NewsMay.07,2025

-

The Timeless Color in Fashion and Textiles

NewsApr.10,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.