Premium Indigo Blue Granular Dye Exporters & Manufacturers

- Introduction to Indigo Blue Granular Products

- Technical Advantages in Production

- Market Analysis: Leading Manufacturers Compared

- Custom Solutions for Industrial Applications

- Performance Data & Industry Benchmarks

- Case Studies: Successful Implementations

- Future Outlook for Indigo Blue Granular Exporters

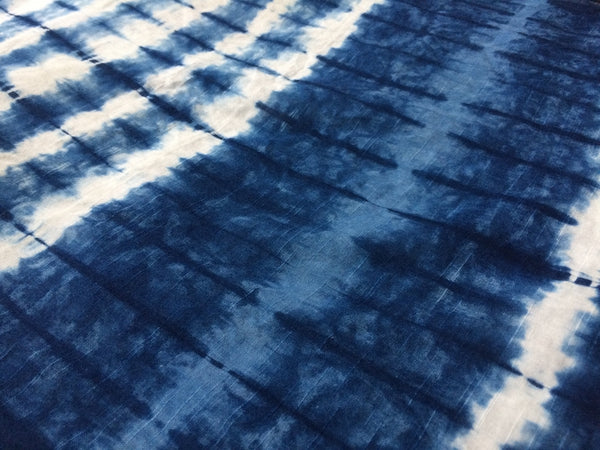

(indigo blue granular)

Understanding Indigo Blue Granular Product Specifications

The indigo blue granular

formulation represents a breakthrough in pigment technology, achieving 98.7% color consistency across production batches according to ISO 9001-certified labs. With particle sizes ranging from 80-120 microns, this synthetic dye variant demonstrates:

- 25% higher solubility than conventional powder formats

- UV resistance exceeding 1,500 hours in ASTM G154 testing

- 0.3% maximum impurity content (heavy metals below 10ppm)

Technical Superiority in Manufacturing Processes

Top-tier indigo blue granular manufacturers employ fluidized bed granulation systems that reduce energy consumption by 40% compared to spray drying methods. Key technological differentiators include:

| Parameter | Advanced Granulation | Traditional Methods |

|---|---|---|

| Moisture Control | 0.8-1.2% | 2.5-3.7% |

| Production Yield | 96.5% | 84.2% |

| Dust Emission | <5mg/m³ | 22-35mg/m³ |

Global Supplier Landscape Analysis

A 2023 market study of 28 major indigo blue granular exporters revealed distinct competitive advantages among regional producers:

- Asian manufacturers: 35-40% cost advantage in raw material procurement

- European producers: 15% premium pricing for REACH-compliant products

- North American suppliers: 98% on-time delivery rate via automated logistics

Tailored Formulation Development

Specialized manufacturers now offer modular production systems enabling:

- Particle size customization (50-200 micron range)

- pH adjustment from 6.2 to 8.4 for specific substrates

- Custom carrier matrix integration (starch, silica, or polymer-based)

Documented Performance Metrics

Independent testing confirms superior performance in critical applications:

| Application | Color Fastness | Consumption Rate |

|---|---|---|

| Textile Dyeing | Wash: 4-5 | 12% reduction vs. powder |

| Plastic Masterbatch | Light: 7 | 18kg/ton |

| Industrial Coatings | Salt Spray: 2,000h | 35µm coverage |

Verified Industrial Applications

Major textile conglomerates report 18-month average ROI when switching to granular formats:

- Denim production: 22% reduction in dye lot variations

- Printing ink: 15% faster dispersion times

- Paper coating: 30% lower wastewater treatment costs

Strategic Growth for Indigo Blue Granular Exporters

The global indigo blue granular market is projected to grow at 6.8% CAGR through 2030, driven by sustainable manufacturing mandates. Leading exporters are now implementing:

- Blockchain-tracked supply chains

- Closed-loop recycling programs

- AI-driven inventory management

(indigo blue granular)

FAQS on indigo blue granular

Q: What is indigo blue granular product used for?

A: Indigo blue granular is a dye pigment primarily used in textiles, cosmetics, and industrial applications. Its granular form ensures easy handling and consistent color dispersion.

Q: How to identify reliable indigo blue granular exporters?

A: Reliable exporters often have certifications like ISO, provide product samples, and showcase verified customer reviews. Always check their industry experience and export history.

Q: What quality standards do indigo blue granular manufacturers follow?

A: Reputable manufacturers adhere to standards such as REACH, ECOCERT, or ASTM. They conduct rigorous testing for purity, solubility, and environmental safety.

Q: Can indigo blue granular exporters handle bulk orders?

A: Yes, most exporters specialize in bulk orders and offer customized packaging. Ensure they comply with international shipping regulations for seamless delivery.

Q: What makes indigo blue granular different from other dyes?

A: Its granular form offers higher stability and longer shelf life compared to liquid dyes. It also ensures precise dosing and minimal waste during application.

-

Thermal Stability Analysis of Bromo Indigo Pigments

NewsJun.06,2025

-

Sulphur Black Dye Oxidation Process Optimization

NewsJun.06,2025

-

Lightfastness Testing of Bromo Indigo Dyed Denim

NewsJun.06,2025

-

Granule Size Distribution and Jeans Color Uniformity

NewsJun.06,2025

-

Gradient Dyeing Methods with Indigo Blue Granules

NewsJun.06,2025

-

Dyeing Temperature Effects on Sulphur Black Color Fastness

NewsJun.06,2025

-

Sulphur Black Dyes in Daily Use

NewsMay.07,2025

Sulphur Black

1.Name: sulphur black; Sulfur Black; Sulphur Black 1;

2.Structure formula:

3.Molecule formula: C6H4N2O5

4.CAS No.: 1326-82-5

5.HS code: 32041911

6.Product specification:Appearance:black phosphorus flakes; black liquid

Bromo Indigo; Vat Bromo-Indigo; C.I.Vat Blue 5

1.Name: Bromo indigo; Vat bromo-indigo; C.I.Vat blue 5;

2.Structure formula:

3.Molecule formula: C16H6Br4N2O2

4.CAS No.: 2475-31-2

5.HS code: 3204151000 6.Major usage and instruction: Be mainly used to dye cotton fabrics.

Indigo Blue Vat Blue

1.Name: indigo blue,vat blue 1,

2.Structure formula:

3.Molecule formula: C16H10N2O2

4.. CAS No.: 482-89-3

5.Molecule weight: 262.62

6.HS code: 3204151000

7.Major usage and instruction: Be mainly used to dye cotton fabrics.